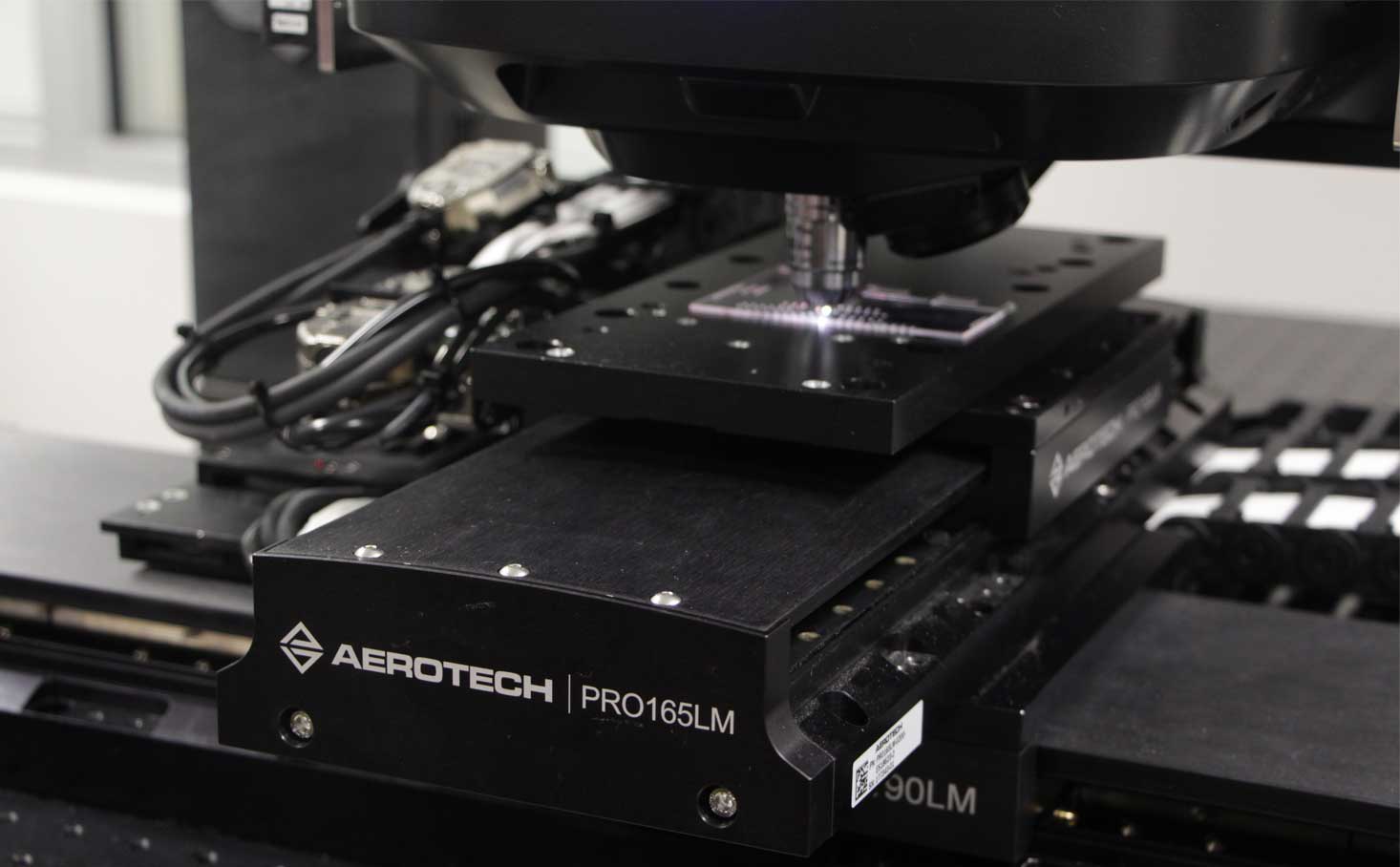

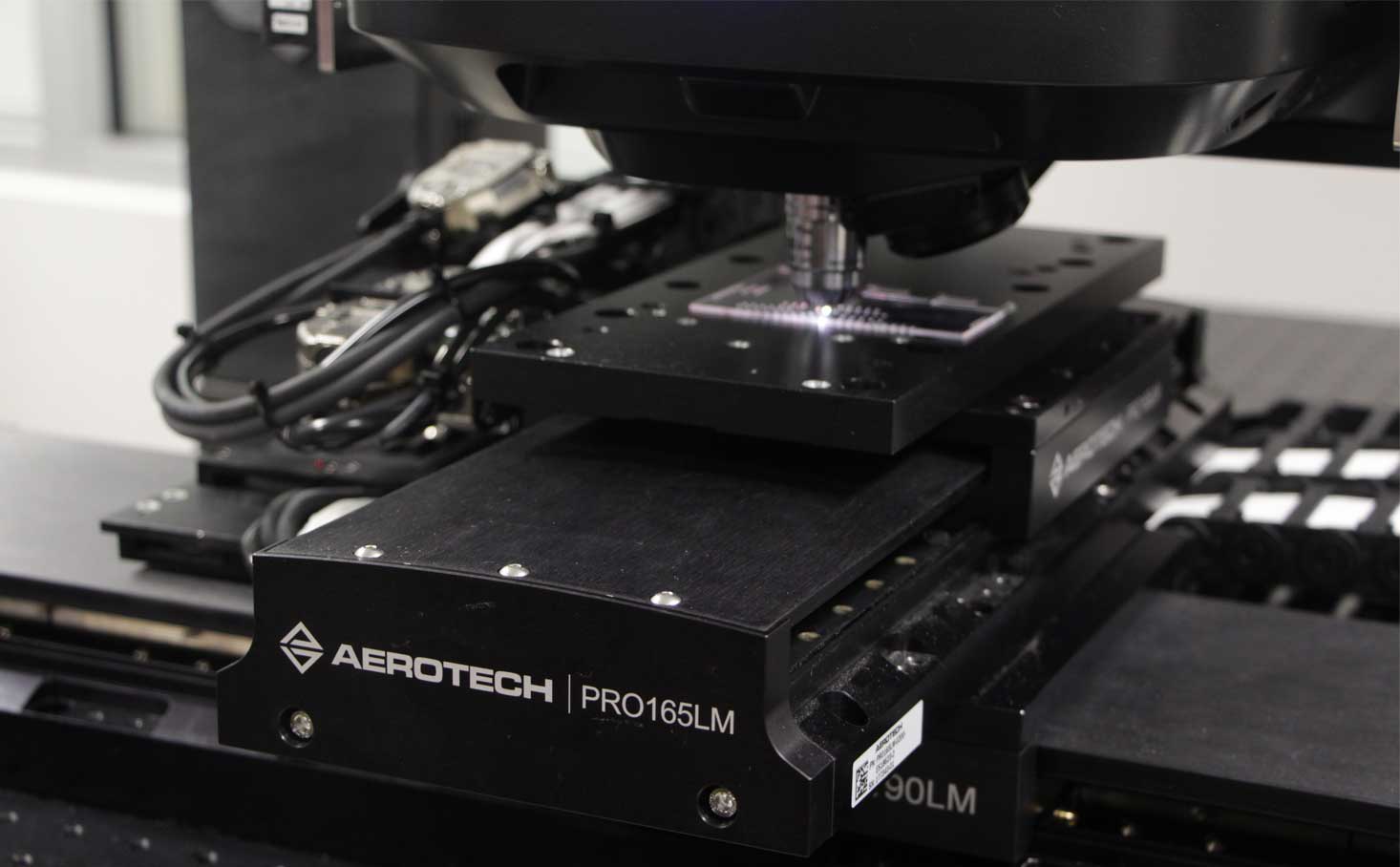

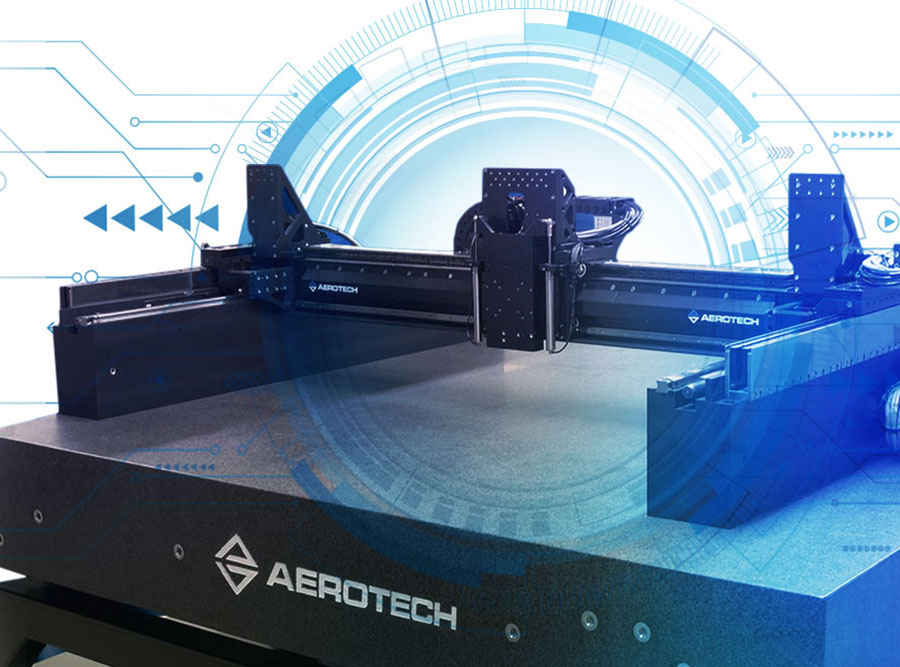

OPTICS INSPECTION

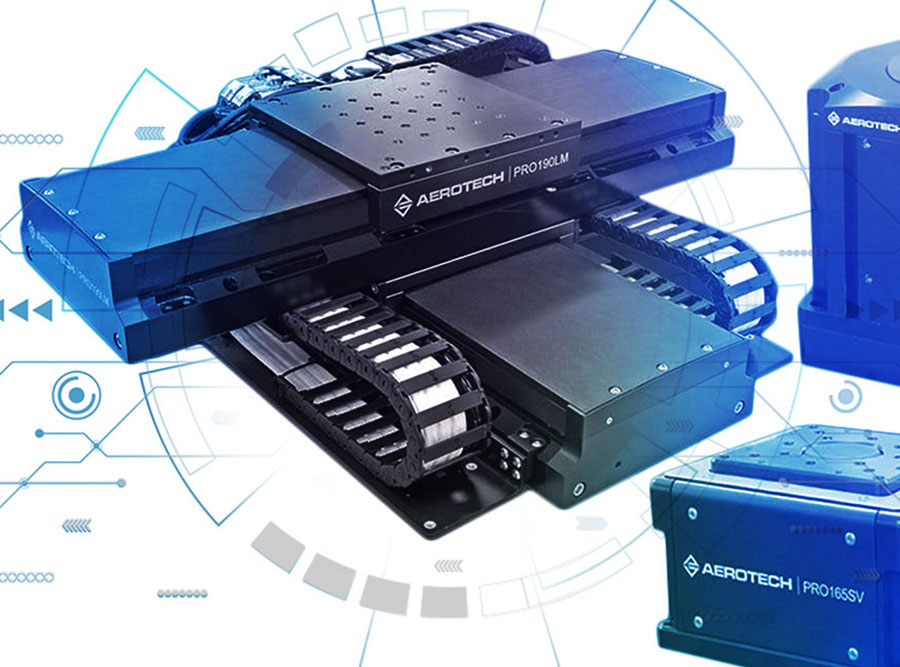

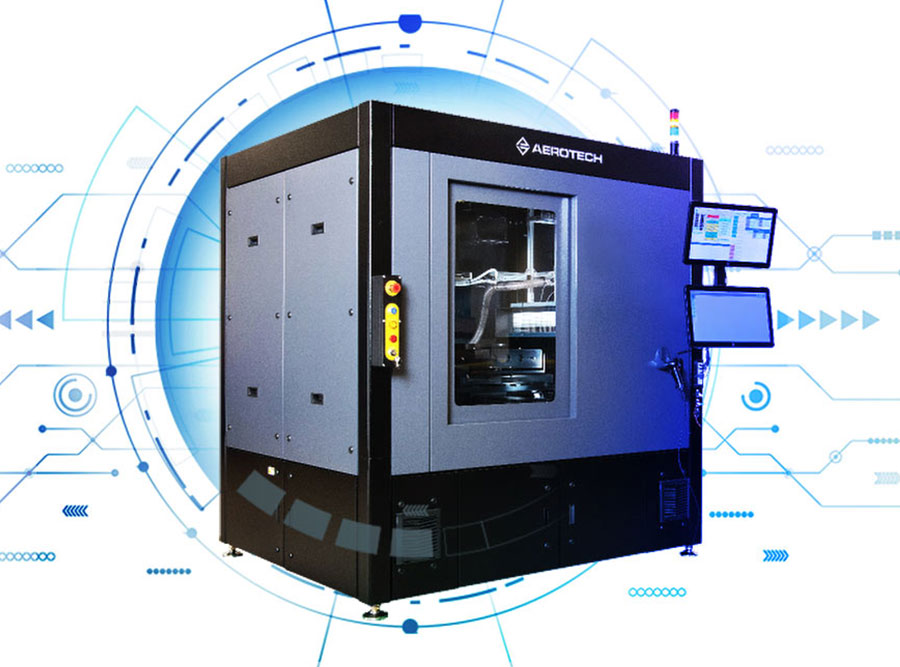

Increase precision while minimizing your machine footprint.

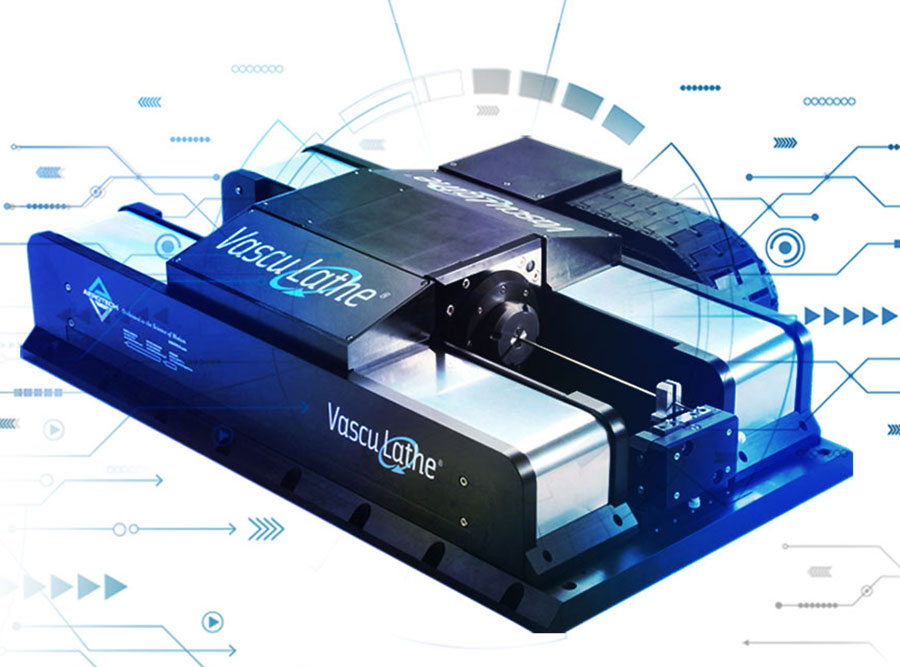

Whether you use non-contact or tactile means to inspect and measure optics, our positioning solutions enhance your process’s precision and reliability.

Low Measurement Uncertainty

Whether you are measuring free-form, asphere or plano surfaces, our precision solutions help you maximize measurement reproducibility and achieve low measurement uncertainty.

Creative Machine Solutions

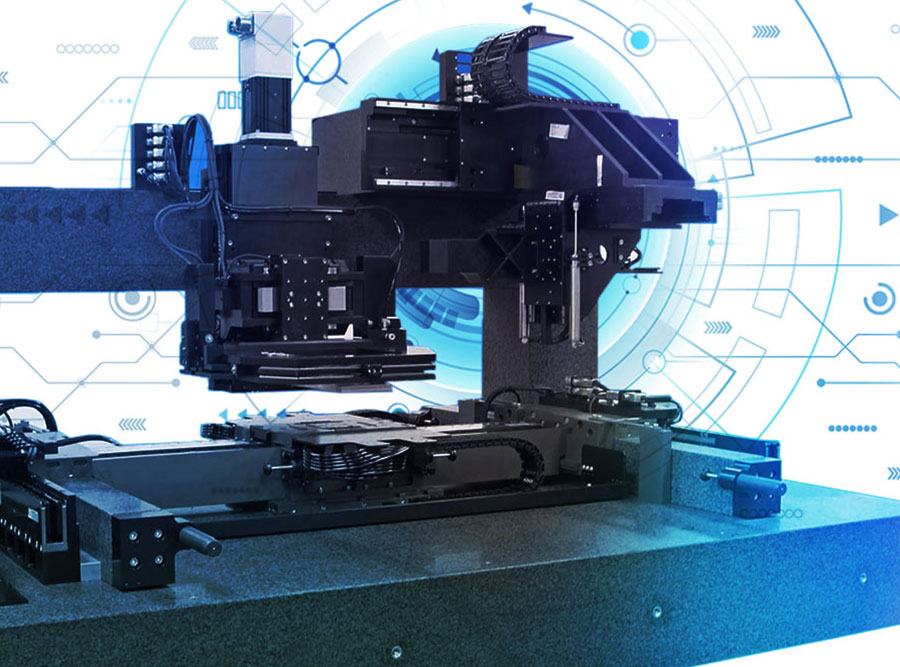

Want to reduce measurement error and increase your metrology throughput? We help you select innovative configurations that are ideal for your process to minimize machine footprint and maximize performance.

Automated Data Collection

We integrate and tie your measurement device output to true position in real time using innovative control features. You’ll trigger, collect and display your measurement data based on real-time, calibrated position feedback.