ACT140DL Direct-Drive Linear Actuator

The ACT140DL high-performance, cost-effective, linear-servomotor-driven actuator is faster and more accurate than a ball screw or belt-drive, and it doesn’t require costly, time-consuming maintenance. An integrated, assembled mechanical system, the ACT140DL eliminates the design complexity and guesswork in choosing and assembling individual components.

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

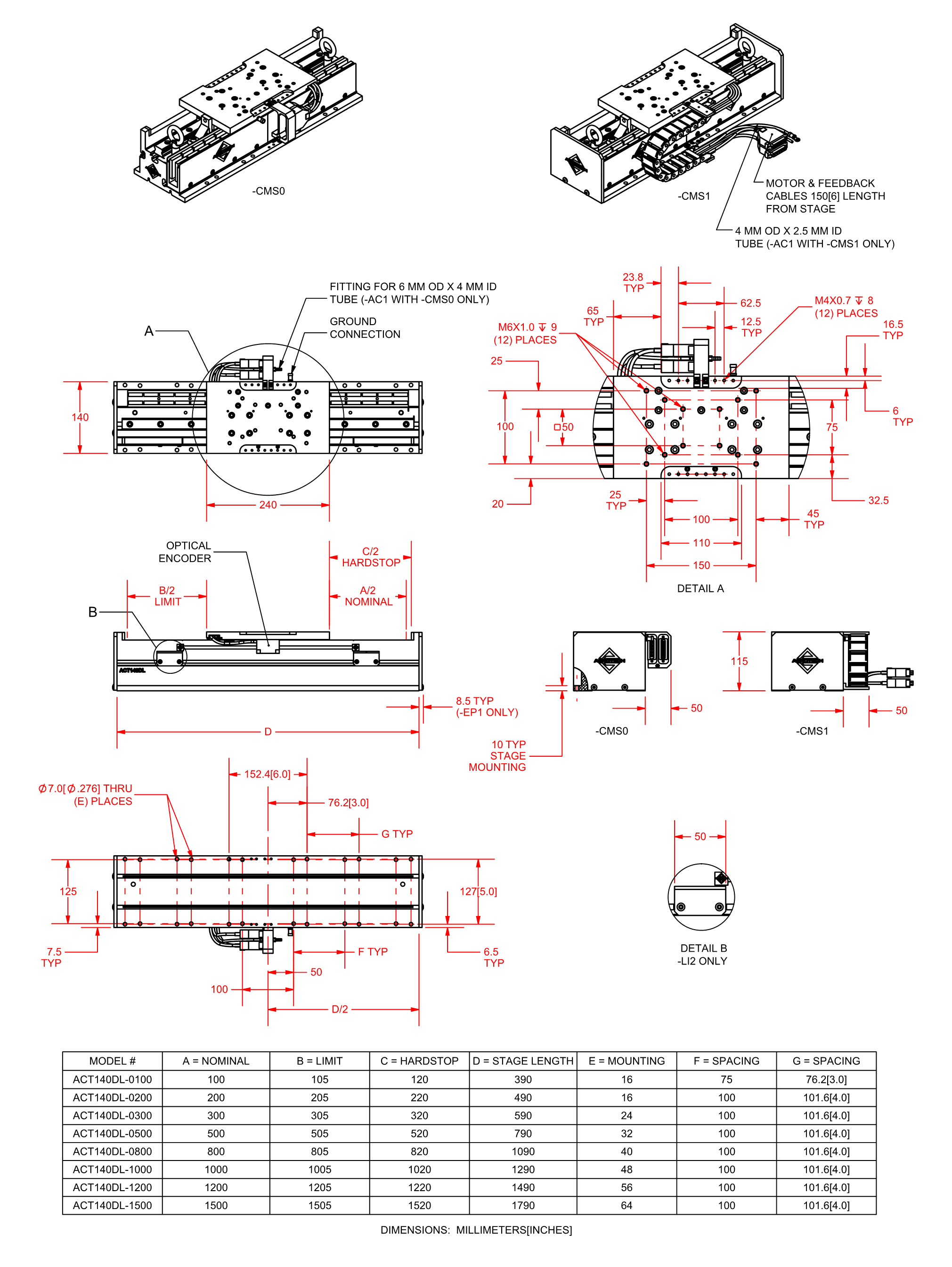

Dimensions

Ordering Info

Downloads

Description

Design Features

- High performance, cost-effective actuator

- Travel range from 100 mm to 1.5 m

- Acceleration capability up to 5 g

- Velocity capability up to 5 m/s

- Maximum continuous force output up to 173.2 N

- Maintenance free, direct drive, zero-cogging motor and noncontact optical linear encoder

The ACT140DL is ideal for applications including assembly, pick and place machines, electronic assembly and qualification, packaging, vision inspection, dispensing, life sciences, image scanning and processing and inkjet printing.

Linear Motor Drive

Aerotech’s high-power, cog-free linear motors drive the ACT series in no load conditions to accelerations of 5 g and a top speed of 5 m/s, enabling the ideal solution to increase throughput. The stiff mechanical structure of the actuator allows for excellent dynamic performance and reduced settling times. The non-magnetic forcer coil provides high force with zero cogging for super-smooth velocity and position control. This zero cogging design is ideal for applications requiring outstanding contour accuracy and smooth velocity profiling. As with all Aerotech linear motor stages, the linear motor has zero backlash, no windup, zero friction and outstanding system responsiveness. The magnetic field of the linear motor is totally self-contained within the U-channel design. Many high-performance applications cannot tolerate the stray magnetic fields generated by flat motor magnet tracks.

High Performance

Noncontact linear optical encoders with micron-level repeatabilities are standard on all ACT series actuators. Either a line-driver output or amplified sine-wave output encoder is available for maximized flexibility. The optional factory calibration further increases standard accuracy and repeatability. Aerotech manufactures a wide range of matching drives and controls to provide a fully integrated and optimized motion solution.

High Reliability

The ACT actuators consist of noncontact linear motors and encoders, making the actuators virtually maintenance-free. As a result, there is no backlash, windup, wear or maintenance that is normally associated with contacting-type systems such as ball screws or belt drives.

Adjustable Options Maximize Application Flexibility

Multiple cable management options allow flexibility in design. For applications requiring a complete solution, a cable management chain is provided. For OEM or applications requiring user-defined cable management, simple connectorized pigtails are available. Moveable limits allow easy adjustment of usable travel for varying application requirements.

Ordering Information

ACT-DL Series Direct-Drive Linear Actuator

| Option | Description |

Model (Required)

| Option | Description |

| ACT115DL | Direct-drive linear actuator |

| ACT140DL | Direct-drive linear actuator |

| ACT165DL | Direct-drive linear actuator |

Travel (Required)

| Option | Description |

| -0100 | 100 mm travel |

| -0200 | 200 mm travel |

| -0300 | 300 mm travel |

| -0500 | 500 mm travel |

| -0800 | 800 mm travel |

| -1000 | 1000 mm travel |

| -1200 | 1200 mm travel |

| -1500 | 1500 mm travel |

Feedback (Required)

| Option | Description |

| -E1 | 20 µm linear encoder, amplified sine (1 Vpp) output |

| -E2 | 0.1 µm linear encoder, line driver (digital TTL) output |

Limits (Required)

| Option | Description |

| -LI1 | Normally-closed limit switches, fixed locations |

| -LI2 | Normally-closed limit switches, adjustable locations |

Cable Management (Required)

| Option | Description |

| -CMS0 | No cable management system |

| -CMS1 | Single axis cable management system |

Air Cooling (Optional)

| Option | Description |

| -AC1 | Forced air cooling for motor |

End Plates (Optional)

| Option | Description |

| -EP1 | End plates mounted to ends of actuator base |

Metrology (Required)

| Option | Description |

| -PL0 | No metrology performance plots |

| -PL1 | Metrology, uncalibrated with performance plots |

| -PL2 | Metrology, calibrated (HALAR) with performance plots |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |