AMG-LP Low-Profile Direct-Drive Gimbals

Aerotech’s AMG-LP (Low Profile) gimbal mounts provide ultra-precise angular position, rate, and acceleration for development and production testing of a wide range of systems. The AMG-LP series is ideal for directing optics, lasers, antennas, and sensors at high speed to precise pointing angles.

Description

Specifications

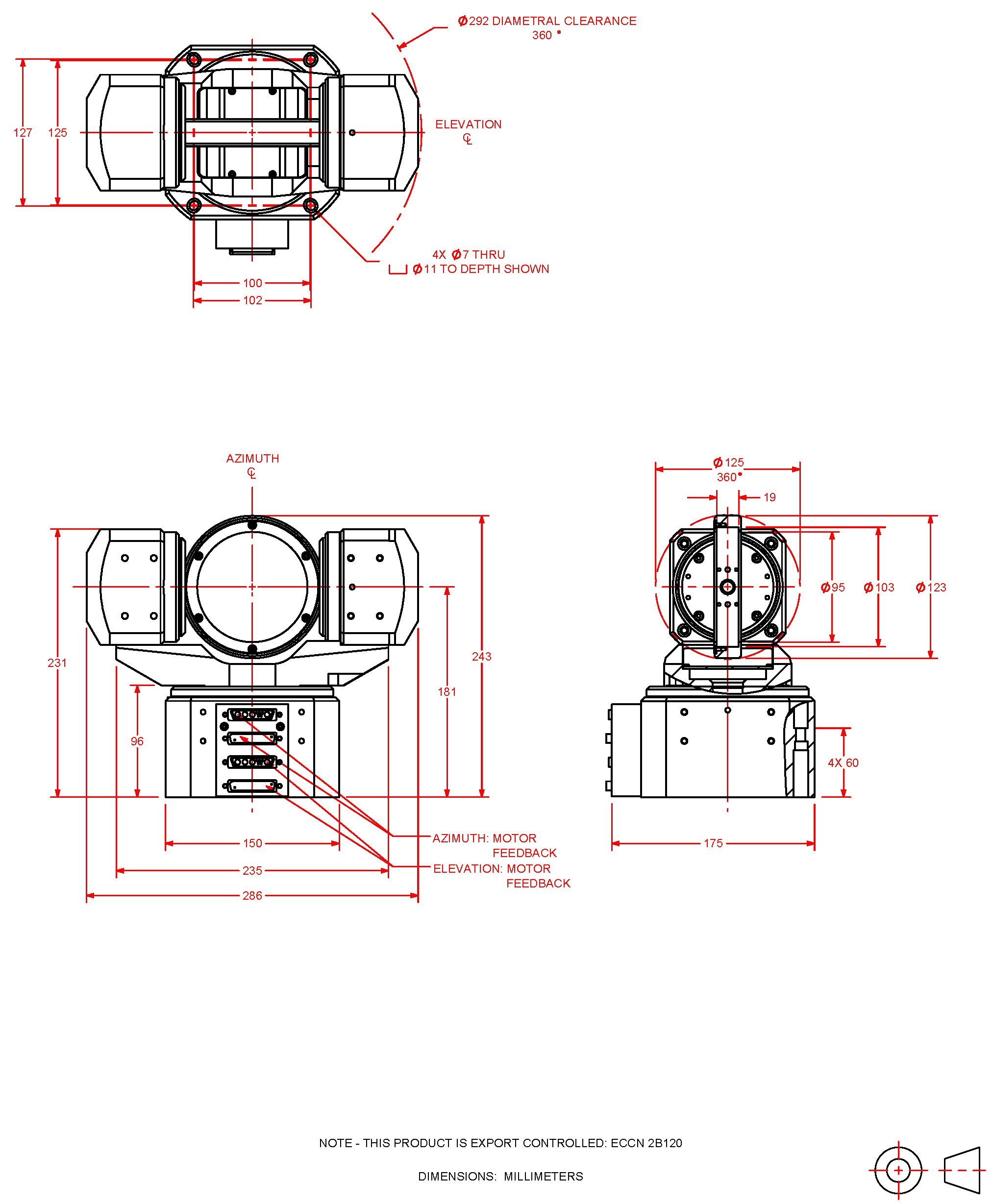

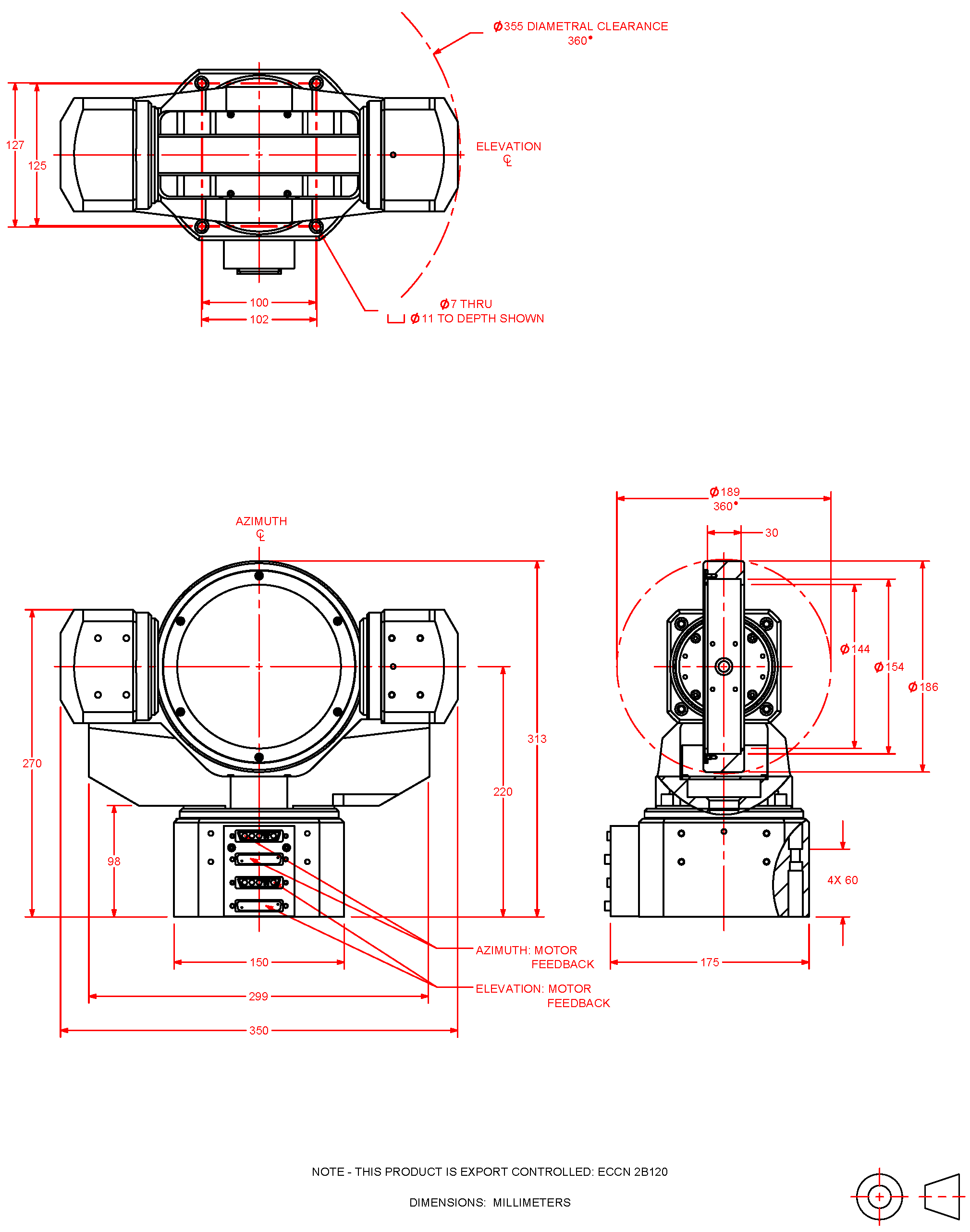

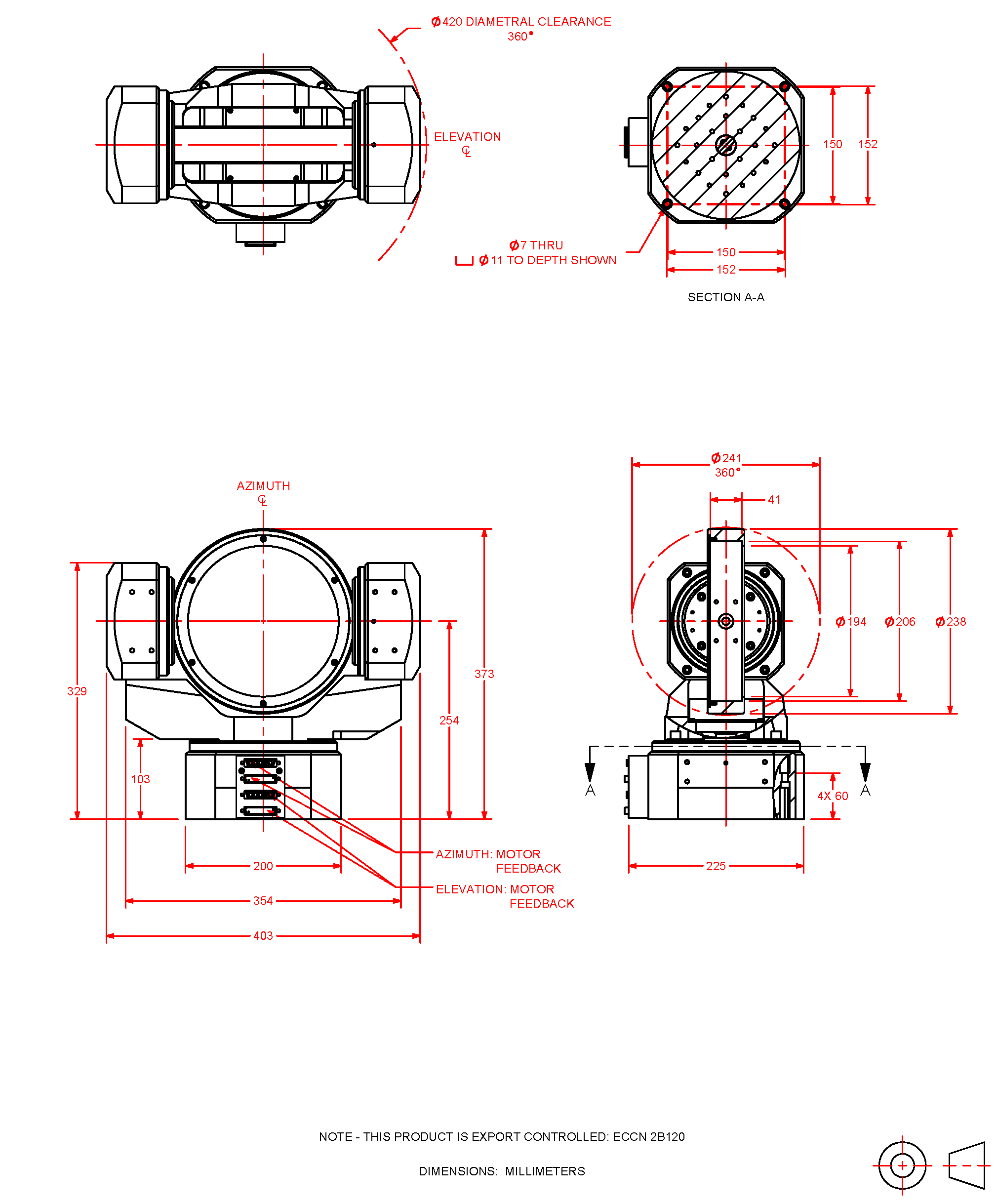

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Continuous 360 degree rotation of azimuth and elevation including built-in slip ring

- High accuracy angular position and rate capability

- Direct-drive brushless servomotors result in zero backlash

- Cog-free design for outstanding velocity stability

- Accommodate loads up to 200 mm in diameter

- Low maintenance and high reliability provide the lowest cost of ownership

Typical applications include missile seeker test and calibration, electro-optical sensor and FLIR testing, optical testing of sensors in a vacuum and angular testing of inertial sensors such as gyros, MEMS and accelerometers. The AMG-LP gimbal provides high performance at an affordable price. The finest quality motors, bearings and encoders are integrated into precision-machined housings to ensure peak performance.

Low Profile

By incorporating our low-profile direct-drive rotary stages, the AMG-LP series is capable of speeds and accelerations that are significantly higher than other competing products of this size. These gimbals have a lower profile compared to competing products within given torque ranges. This results in a smaller and more effective gimbal for many applications where beam height and chamber volume are of utmost concern.

Accurate 360° Positioning and Rate Generation

Direct-drive brushless torque motors, with rare-earth magnets and high-accuracy angular transducers are coupled directly to precision shafts for accurate and smooth 360° continuous motion. The absence of gear trains and other drive mechanisms eliminates position error contributions due to mechanical hysteresis and backlash. Directly-coupled high-resolution position feedback devices ensure highly accurate and repeatable positioning.

A wide range of performance feedback grades is available. Typical line gimbal resolution ranges from 0.87 to 0.32 µrad with Aerotech controls. A built-in azimuth slip ring provides for continuous rotation with no cable wrap-up.

Mirror and Alternate Payload Accommodation

A variety of mirror cell diameters are available for standard optic applications. We also provide for custom payload attachment solutions for various device interfaces. Each gimbal mirror cell can be modified or replaced with different shaped cells to accommodate sensors or other odd shaped payloads.

Direct-Drive Motors for Outstanding Control

To maximize positioning and velocity performance, AMG-LP gimbal mounts utilize Aerotech’s high torque S-series brushless, slotless servomotors. These motors have all of the advantages of a brushless direct-drive motor — no brushes to wear, no gear trains to maintain, high acceleration, and high speeds. Since it is a slotless, ironless design, there is zero cogging, meaning there is absolutely no torque ripple. This results in smoother motion throughout travel and more precise positioning. These motors are available in different winding configurations to work with high- or low-voltage power supplies.

Ordering Information

AMG-LP Low Profile Direct-Drive Gimbals

| Option | Description |

| AMG100LP | AMG100 low-profile direct-drive gimbal |

| AMG150LP | AMG150 low-profile direct-drive gimbal |

| AMG200LP | AMG200 low-profile direct-drive gimbal |

Feedback (Required)

| Option | Description |

| -E1 | Incremental encoder, 1 Vpp |

| -E2 | Incremental encoder, TTL, x5 interpolation |

| -E3 | Incremental encoder, TTL, x10 interpolation |

| -E4 | Incremental encoder, TTL, x25 interpolation |

| -E5 | Incremental encoder, TTL, x50 interpolation |

Metrology (Required)

| Option | Description |

| -PL1 | Metrology, uncalibrated with performance plots |

| -PL2 | Metrology, calibrated (HALAR) wtih performance plots |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system

Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components

Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |