LaserTurn1 Laser Machining System

The LaserTurn®1 cylindrical laser machining system supports material from 0.1 mm to 7.9 mm in diameter, making it an ideal platform for the manufacture of cardiovascular and neural stents. The system can be configured for wet or dry cutting and includes options for material advance and bushing alignment platforms. The integrated linear-rotary system combines automated material handling functionality with high performance direct-drive linear and rotary motion.

Description

Specifications

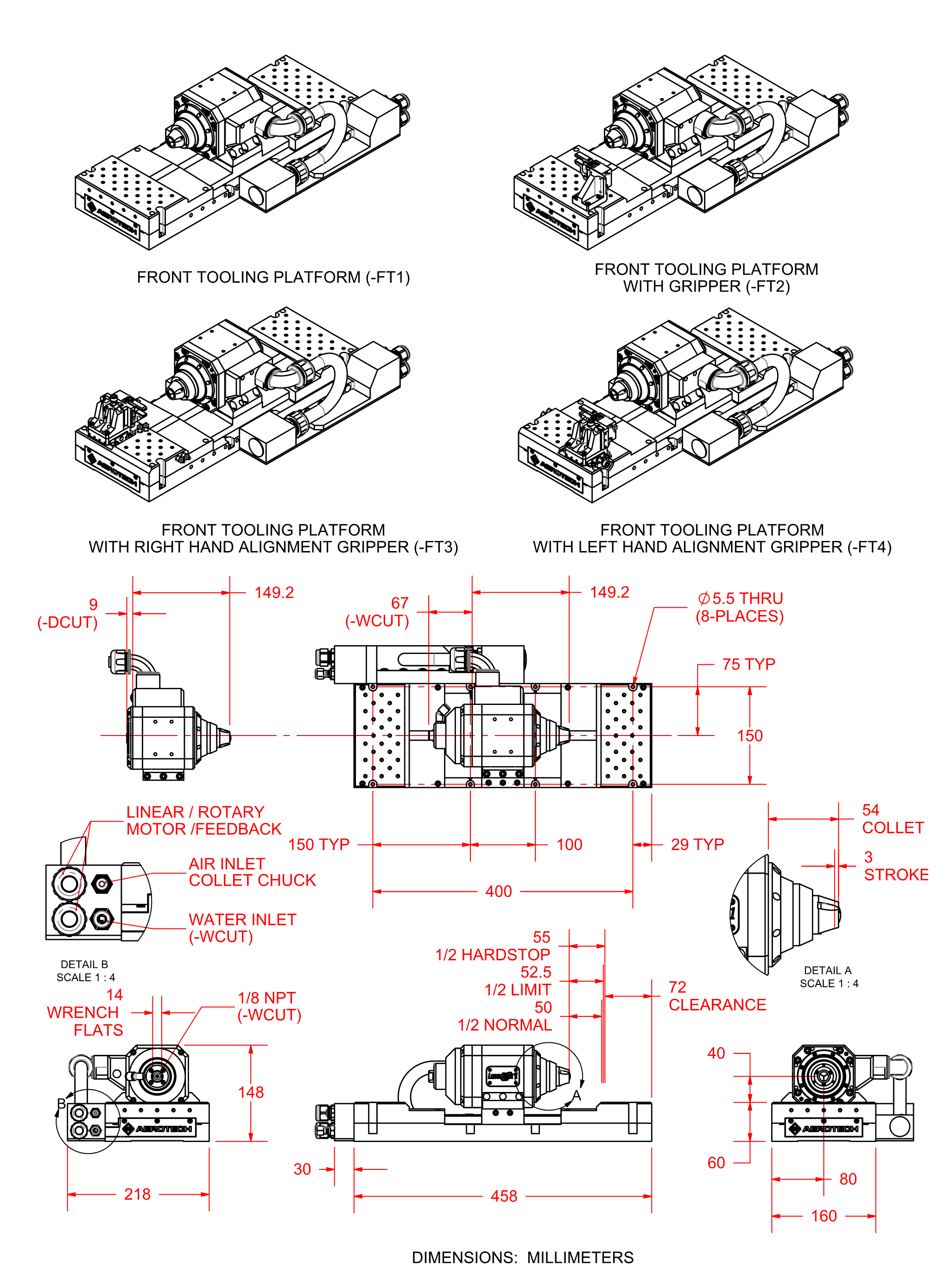

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- High integration linear/rotary motion platform

- Pneumatically-actuated collet closer supports 0.1 mm to 7.9 mm O.D. materials with frictionless rotary union

- Clear aperture for product feed-through

- Standard front and rear tooling platforms

- Direct-drive linear and rotary motor technology

- Configure for wet or dry cutting

Integral Tooling Platform

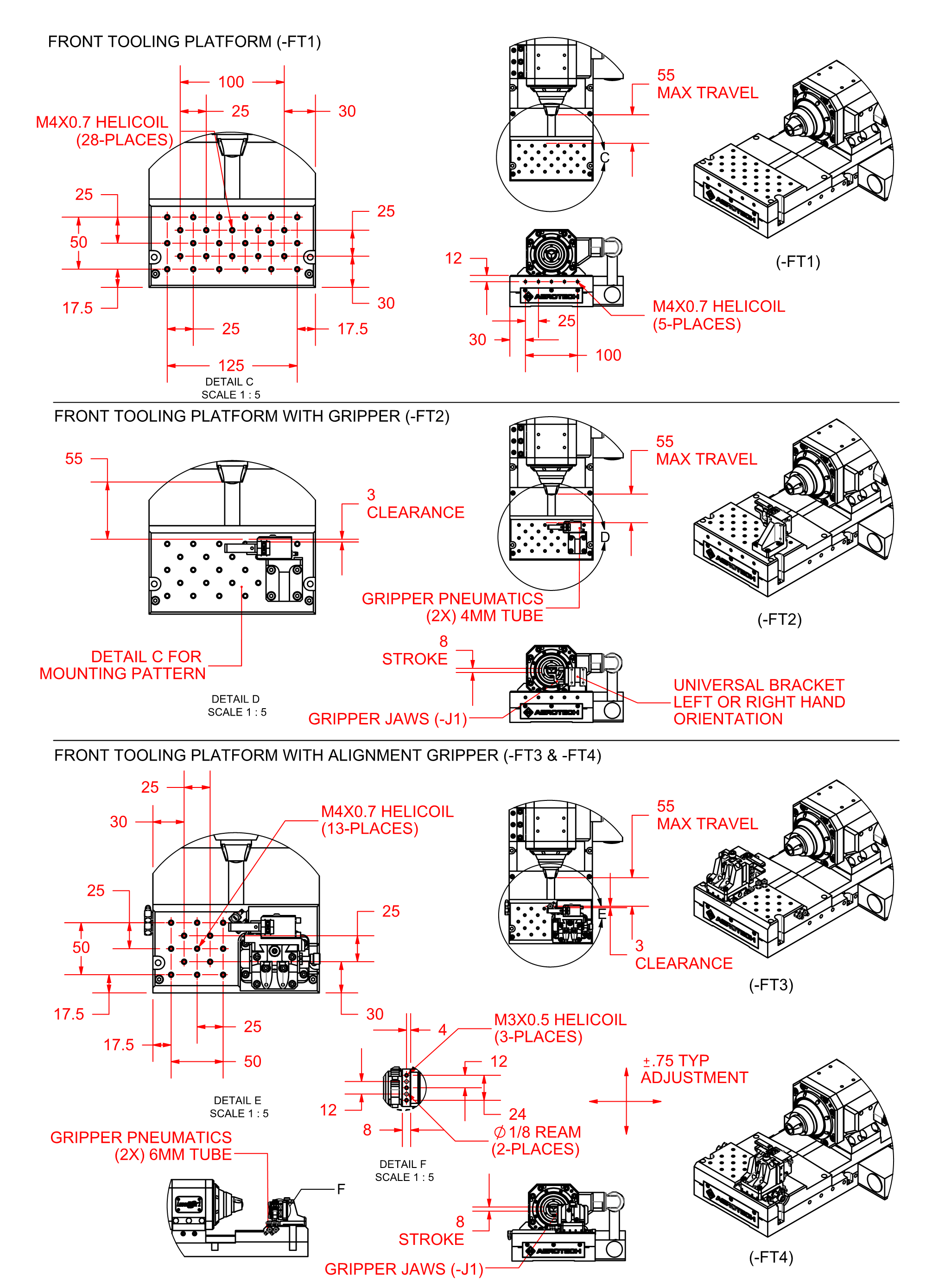

The LaserTurn1 includes standard front and rear tooling platforms with M4 mounting features. The tooling platforms are bolted directly to the base of the linear stage providing a stiff, monolithic, common inertial frame of reference. Fixtures such as bushing alignment assemblies, part collection, or automated material advance functions can be attached easily.

Automated Material Handling

The LaserTurn1 is a complete motion and material handling subsystem. The system includes an automated, pneumatically activated Type D collet closer. The collet closer has a clear aperture for product feed through and can support tubing diameters from 0.1 mm (0.0039 in) to 7.9 mm (0.3125 in) in dry cutting applications and up to 3 mm (0.118 in) when configured for wet cutting operation. The collet closer is designed to minimize axial tube motion during clamping operations by keeping the collet stationary and moving the tapered mating surface during collet open/close operation.

Direct-Drive Technology

The LaserTurn1 series utilizes direct-drive noncontact motor and encoder technology for both the linear and rotary axes. Direct-drive motors exhibit significantly higher throughput and maintenance-free operation when compared to gear and screw-driven technology. Linear and rotary encoders coupled directly to the load have the highest level of system accuracy and repeatability over the operating lifetime of the stage.

Noncontacting Labyrinth Cover Design

The overlapping hard cover design protects the linear stage of the LaserTurn1 from contact with fluids used in wet cutting processes. The sloped hard covers provide robust protection from fluid and machining byproduct ingress as well as incidental operator contact that may occur during part changeover.

Advanced Control Architecture

The LaserTurn1 is available with Aerotech’s Automation1 Software-Based Machine Controller (iSMC). The Automation1-iSMC is a part of the Automation1 high-performance motion control platform which also includes the Automation1 Motion Development Kit (MDK). Automation1 drives are networked to the controller over the HyperWire® fiber optic communication bus. This ultra-fast bus and premium servo motor drive hardware enable new levels of optimization across several axes of motion. Advanced trajectory generation capabilities such as multi-block look-ahead minimize geometric errors in tight profiles by transparently regulating cutting speed. Aerotech’s Position Synchronized Laser Firing Output (PSO) functionality automatically adjusts the laser pulse frequency to match the current cutting speed to maintain optimal laser power coupling.

Ordering Information

Cutting Configuration Option

| Option | Description |

| -DCUT | Dry cutting configuration |

| -WCUT | Wet cutting configuration with fluid rotary union |

Front Tooling Options

| Option | Description |

| -FT1 | Front tooling platform |

| -FT2 | Front tooling platform with gripper |

| -FT3 | Front tooling platform with right-hand alignment gripper |

| -FT4 | Front tooling platform with left-hand alignment gripper |

Gripper Jaws (Optional)

| Option | Description |

| -J1 | Gripper jaws for 0-8 mm tube diameters |

Metrology - Linear (Required)

| Option | Description |

| -PL1 | Metrology, uncalibrated with performance plots |

| -PL2 | Metrology, calibrated (HALAR) with performance plots |

- Metrology option applies to linear axis only.

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

Accessories (ordered as separate items)

| Option | Description |

| Collet-D-CLTxx | Levin type D collet, 0.1 mm to 8 mm part diameter sizes available |

| RingSeal-D-RSxx | Ring seal for wet cutting - consult with Aerotech for available sizes |

| CGF | Collet and Gripper Filtration Kit |