S Series Brushless, Frameless Torque Motors

The S-series motors are Aerotech’s high-performance brushless, frameless torque motors. The motors feature rare-earth magnets for maximum torque and acceleration in a compact assembly – while delivering excellent velocity stability.

Interested in buying online? Learn more here.

Description

Specifications

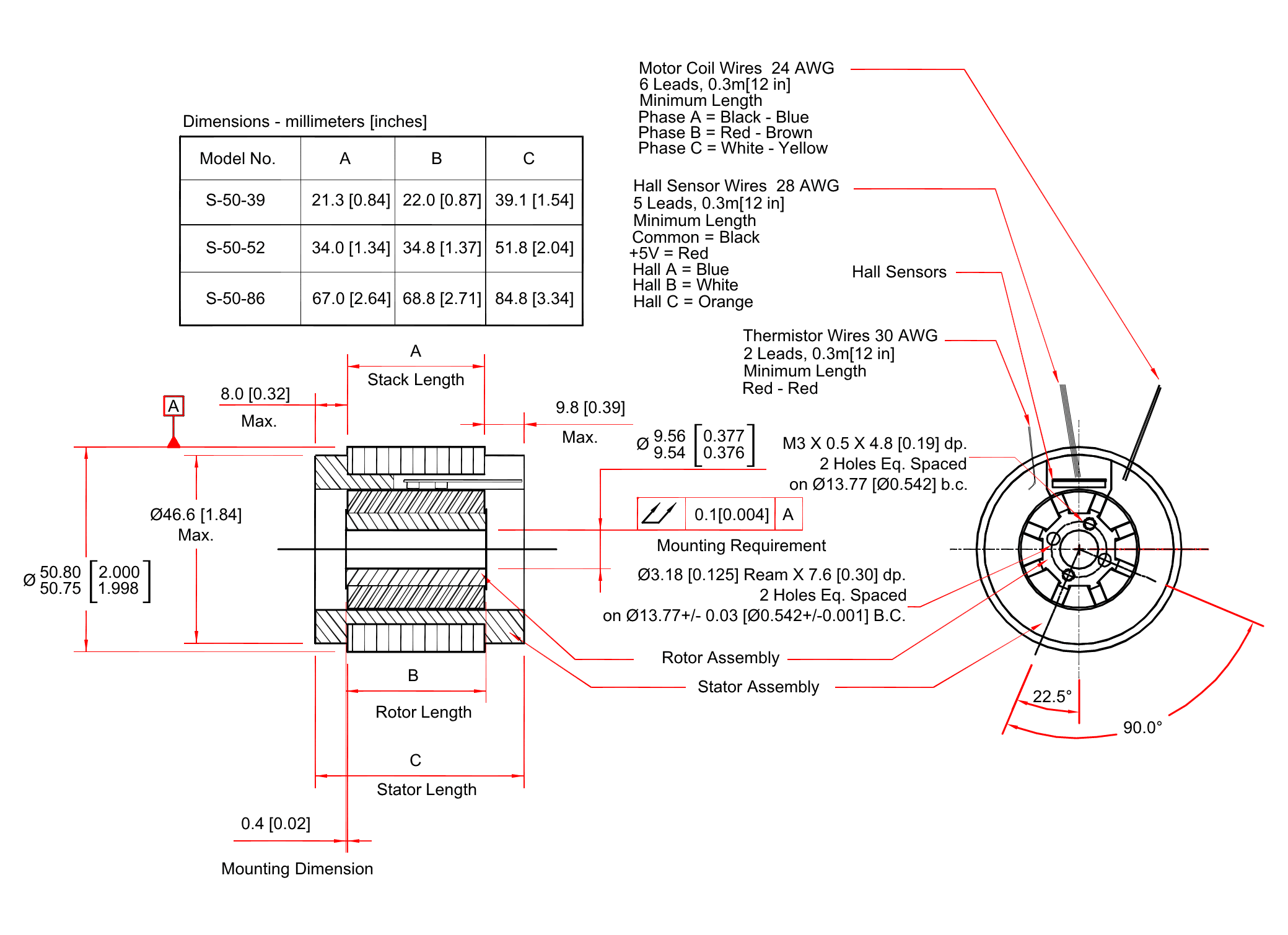

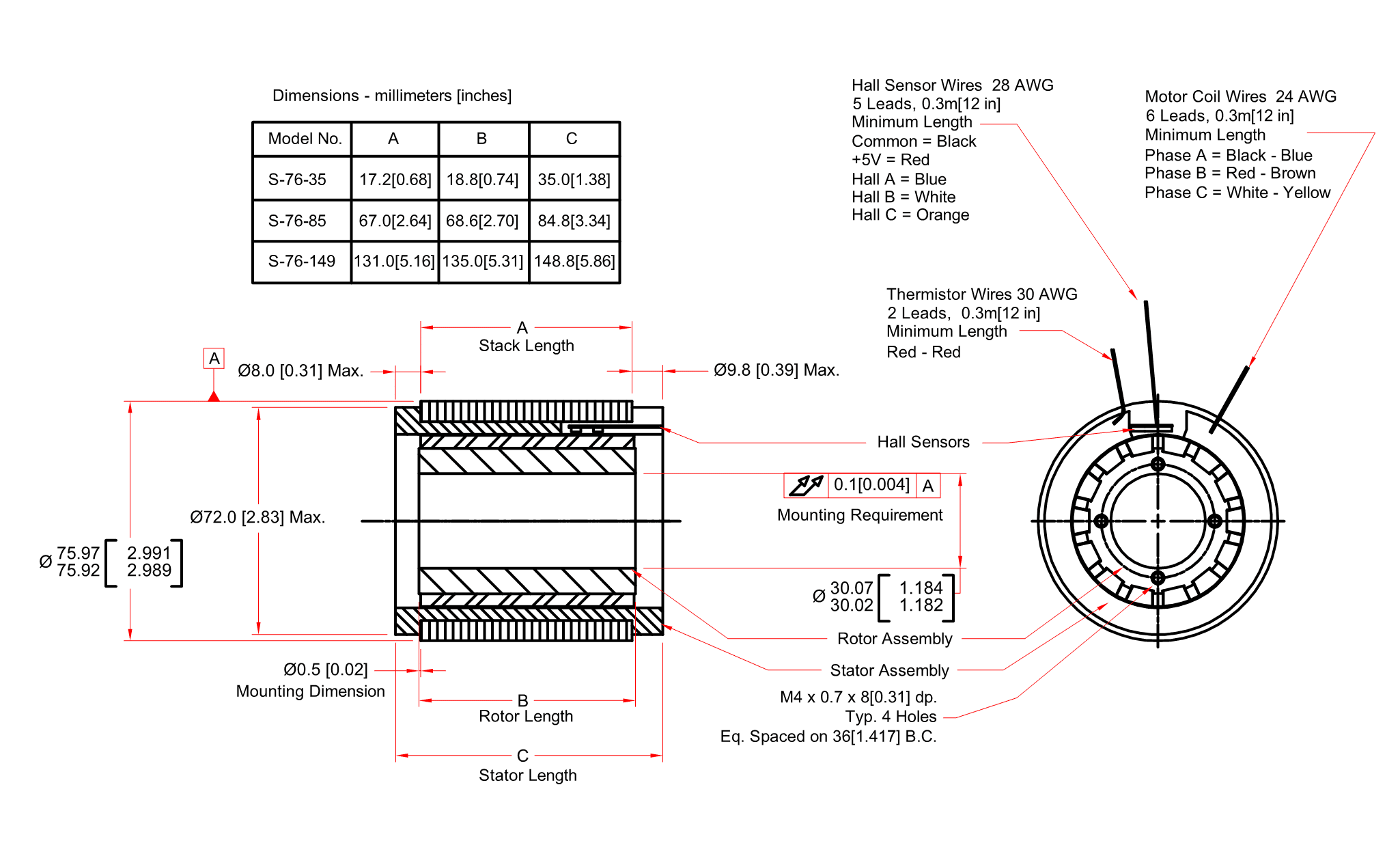

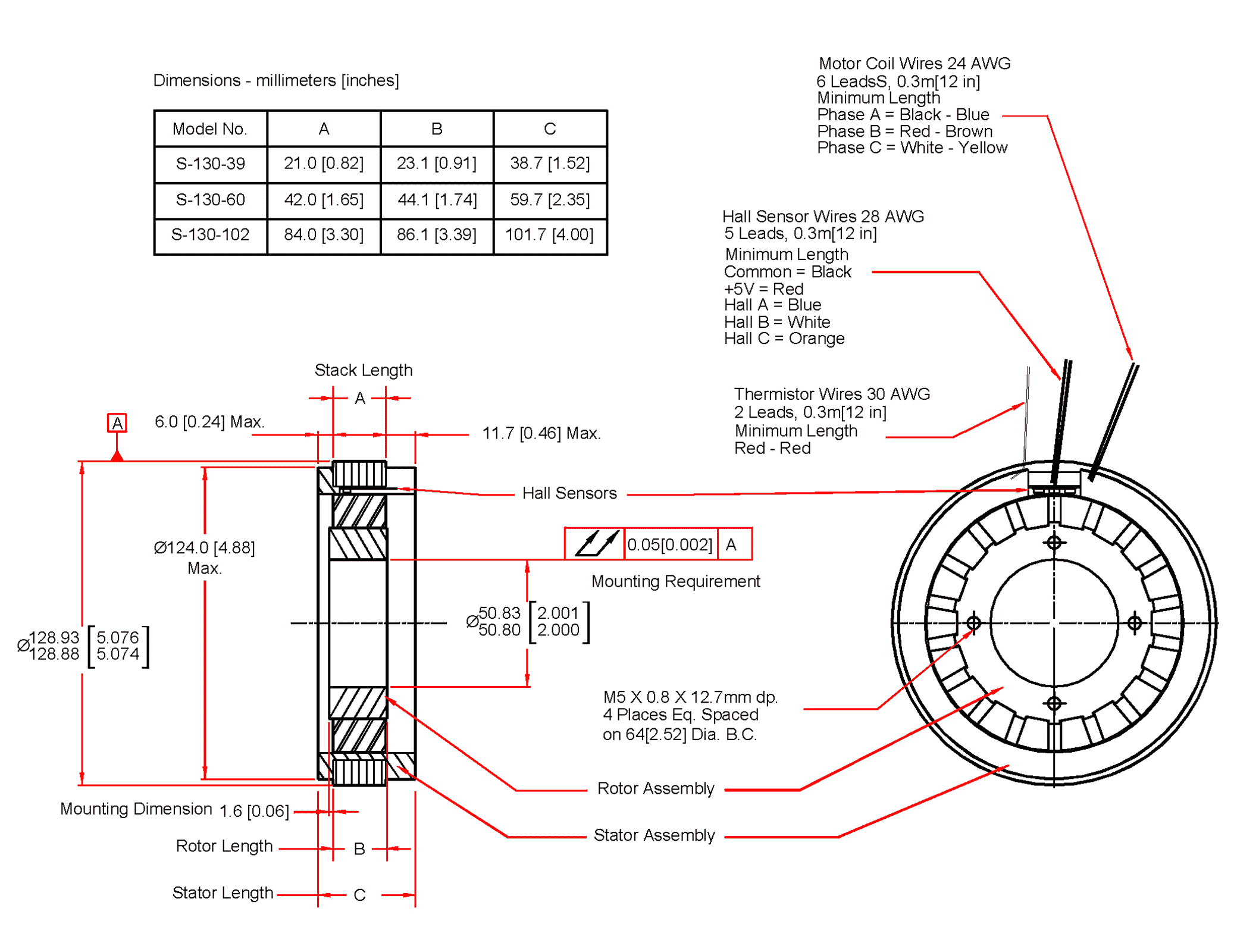

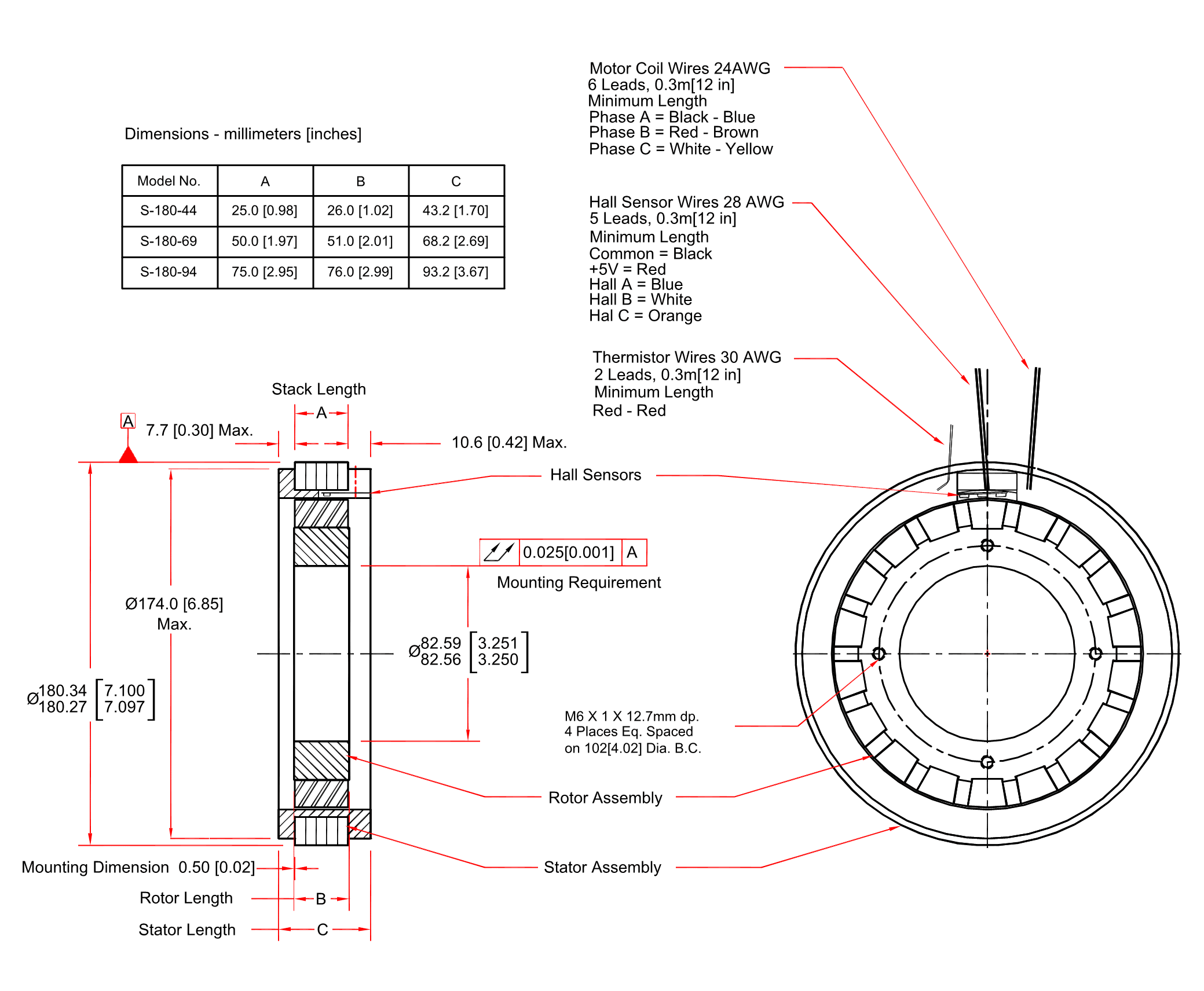

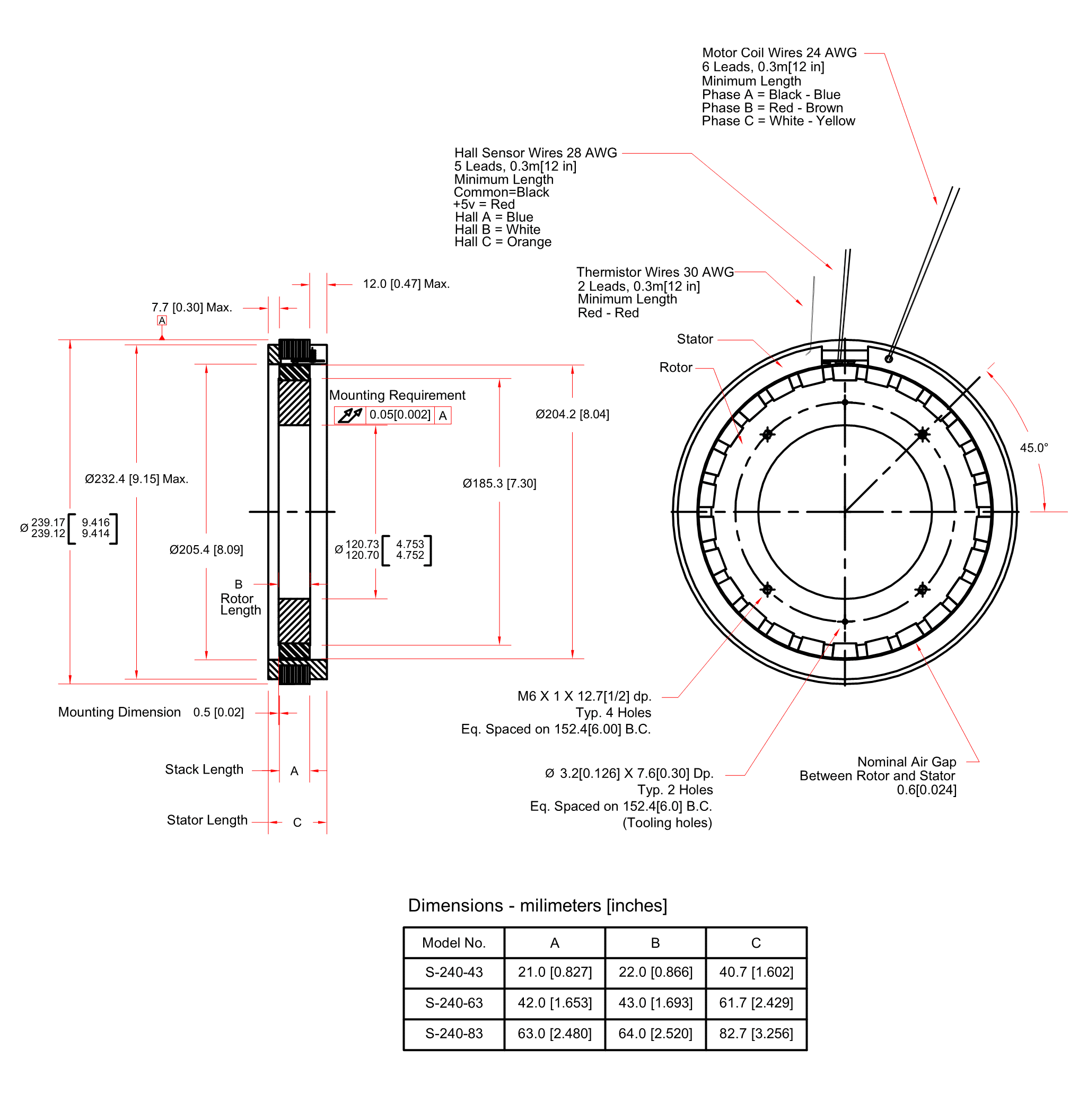

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Slotless, brushless ring motors with high torque output and zero cogging

- Frameless design for easy integration into OEM machines

- Various winding options available

- Includes Hall effect sensors for commutation

- CE approved, follows the EU 2015/863 RoHS 3 directive

High-Performance Design

The S-series motors utilize a slotless stator design and high pole-count rotor to provide zero cogging for exceptional velocity stability. The laminations contain no slots, eliminating torque ripple and cogging torque that produces velocity disturbance. The S-series motors are well-suited for direct-drive applications such as printing and scanning where velocity ripple cannot be tolerated.

Wide Range of Output Torque and Sizes

The S-series slotless motors cover a wide range of torque and package sizes. Continuous torque ranges from 0.20 N·m to 29.09 N·m. Peak torque ranges from 0.82 N·m to 116.37 N·m. The open design of the S-series motors allows for custom winding or mechanical variations to meet any application need.

The S-series motors are designed for applications in OEM machines. The S-50 (50 mm diameter) motor is ideal for small, tight spaces such as spindles or small feed rolls. The S-180 (180 mm diameter) and S-240 (240 mm diameter) can accelerate large print drums or precision positioning tables.

Easy Machine Integration

All S-series motors are supplied as two pieces – a slotless stator and a permanent magnet rotor. The stator is a standard 3-phase winding assembly with Hall-effect devices. They can be driven using a simple six-step or sinusoidal commutation algorithm. Aerotech’s Ndrive series amplifiers are performance-matched to the S-series motors for easy integration. The hollow rotor mounts directly to a drive axis with no gearing required.

Custom variations can be engineered to your requirements with minimal lead time.

Need help sizing your motor? Try Aerotech's Motor Sizer software to specify the ideal motor for your application.

Ordering Information

Slotless Torque Ring "Kit" Servomotors

| Option | Description |

| S-50-39 | Slotless motor, rotor, and stator, 50 mm O.D., 39 mm length. |

| S-50-52 | Slotless motor, rotor, and stator, 50 mm O.D., 52 mm length. |

| S-50-86 | Slotless motor, rotor, and stator, 50 mm O.D., 86 mm length. |

| S-76-35 | Slotless motor, rotor, and stator, 76 mm O.D., 35 mm length. |

| S-76-85 | Slotless motor, rotor, and stator, 76 mm O.D., 85 mm length. |

| S-76-149 | Slotless motor, rotor, and stator, 76 mm O.D., 149 mm length. |

| S-130-39 | Slotless motor, rotor, and stator, 130 mm O.D., 39 mm length. |

| S-130-60 | Slotless motor, rotor, and stator, 130 mm O.D., 60 mm length. |

| S-130-102 | Slotless motor, rotor, and stator, 130 mm O.D., 102 mm length. |

| S-180-44 | Slotless motor, rotor, and stator, 180 mm O.D., 44 mm length. |

| S-180-69 | Slotless motor, rotor, and stator, 180 mm O.D., 69 mm length. |

| S-180-94 | Slotless motor, rotor, and stator, 180 mm O.D., 94 mm length. |

| S-240-43 | Slotless motor, rotor, and stator, 240 mm O.D., 43 mm length. |

| S-240-63 | Slotless motor, rotor, and stator, 240 mm O.D., 63 mm length. |

| S-240-83 | Slotless motor, rotor, and stator, 240 mm O.D., 83 mm length. |

- S-Series torque ring motors include the stator w/flying leads, adjustable-phase Hall bd., and rotor w/magnets.

Winding Designation (Required)

| Option | Description |

| -A | 76 cm (2.5 ft) flying leads std |

- Contact factory to inquire about or check availability of alternate winding options.

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |