ABL8000 Air-Bearing Direct-Drive Linear Stage

The ABL8000 direct-drive, wide-body linear air bearing stage features an air-on-air preload, exceptionally high stiffness and excellent geometric characteristics, in order to meet the precision positioning demands of leading-edge manufacturing and inspection applications.

Description

Specifications

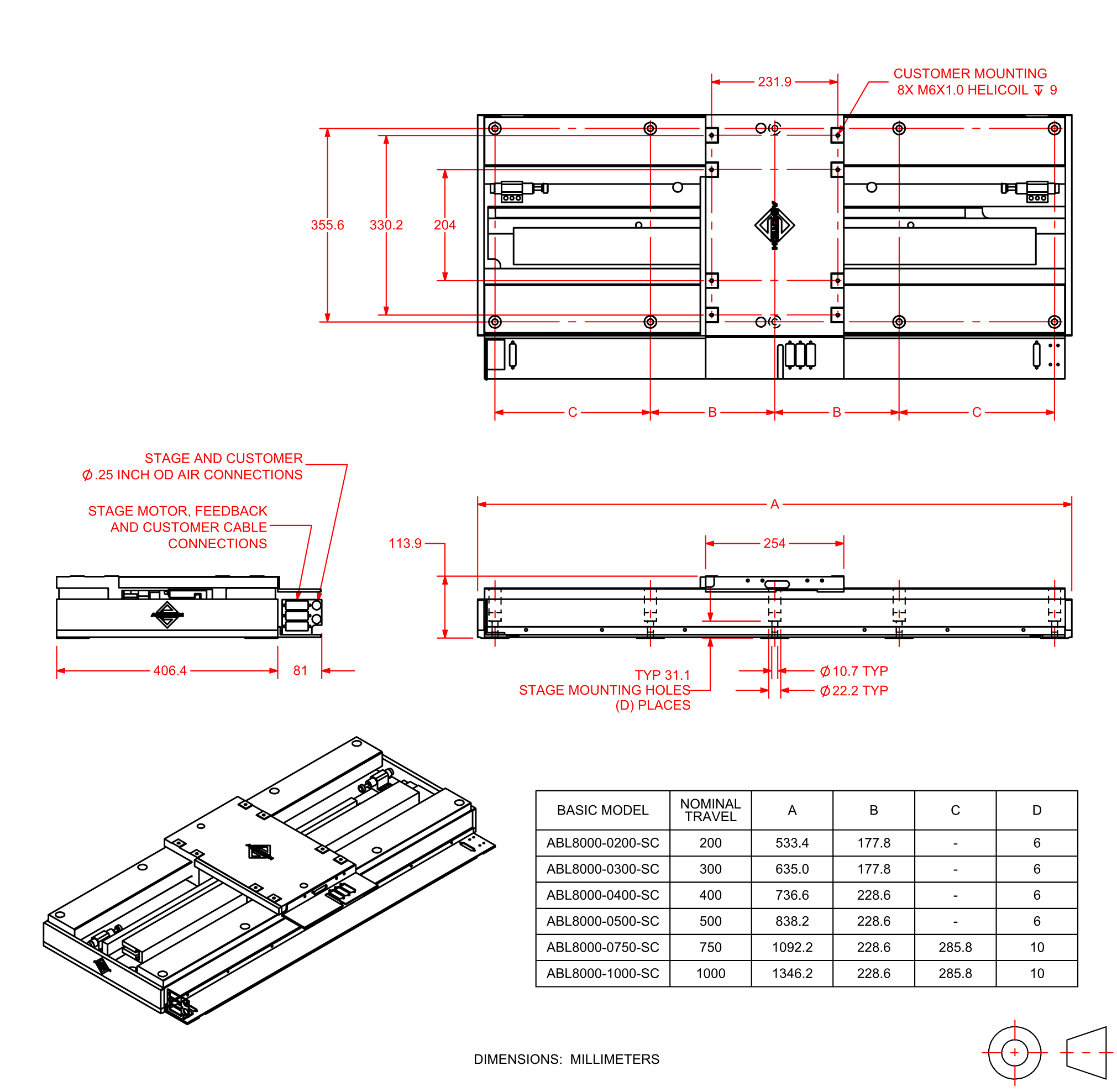

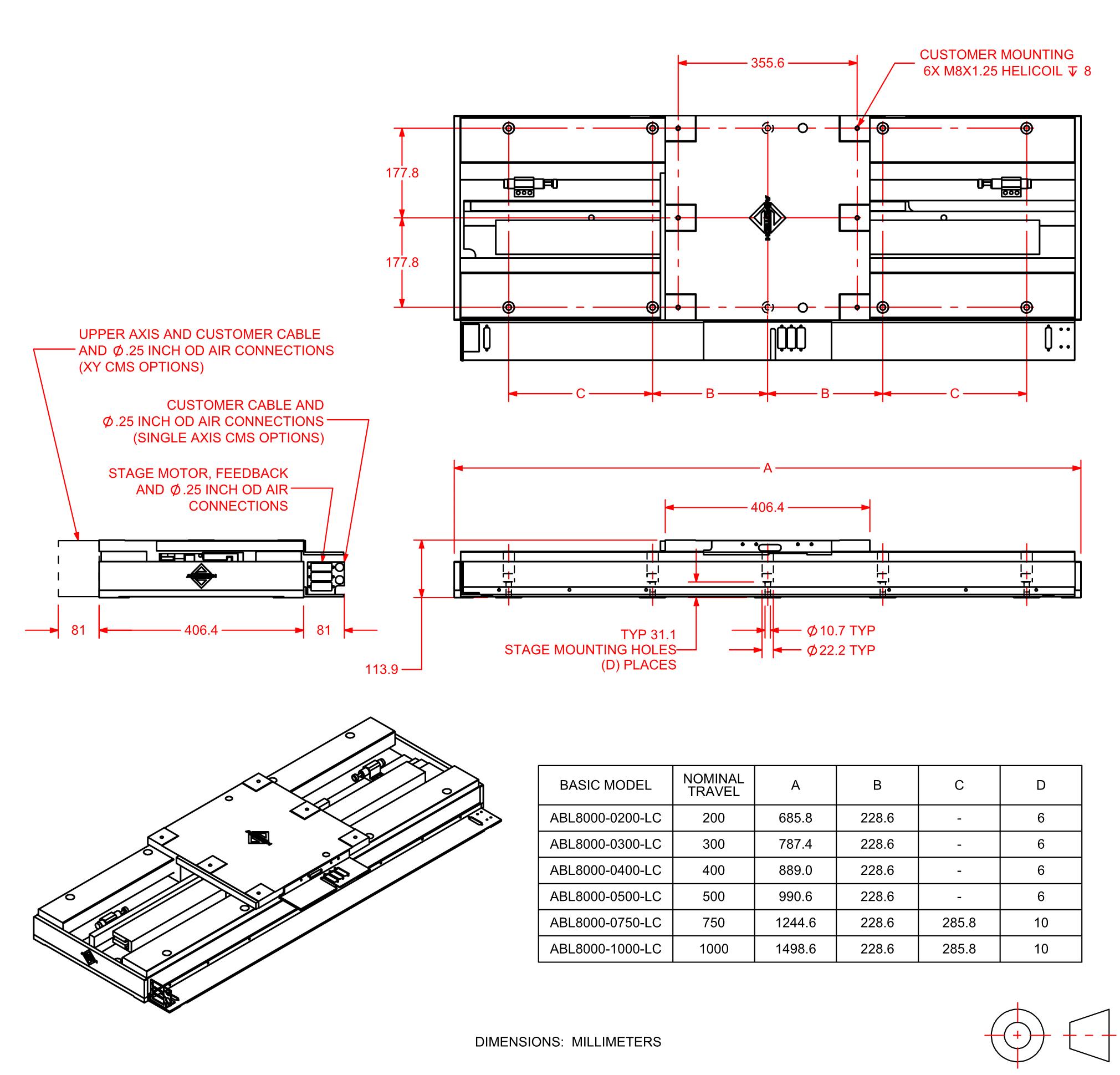

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Available with up to 1000 mm travel

- High-accuracy linear encoder

Air-Bearing Design

The ABL8000 incorporates an active preload on both the vertical and horizontal surfaces. The opposing thin-film pressure maintains the bearing nominal gap tolerance. This design, in addition to the large air-bearing surface that distributes the load over a large surface area, results in a stage with outstanding stiffness that is ideal for heavy or offset loading.

Proprietary manufacturing techniques result in a stage with unsurpassed geometric characteristics. The air bearing has an inherent averaging effect that maximizes performance. The thin film will fill small surface voids and allow for other irregularities. This characteristic yields superior pitch, roll, yaw, straightness and flatness specifications.

Linear Motor Drive

The driving force behind this stage is Aerotech’s BLM series brushless linear servomotor. Aerotech’s long history and experience as a motor manufacturer is reflected in this design. The BLM utilizes an ironless forcer, which means there is zero cogging and no attractive forces – resulting in unsurpassed smoothness of motion. Capable of generating high force and velocity, the BLM represents the ultimate combination of power and performance.

Zero Maintenance

Our totally noncontact air bearing, noncontact linear motor drive and noncontact feedback device ensure years of maintenance-free operation at the high performance levels that are expected of Aerotech equipment. Because there is no mechanical contact between moving elements, the ABL8000 experiences no wear or reduction in performance over time. Service life is virtually unlimited and since there is no lubrication – only clean, dry gas – air bearings are ideal for clean room and medical applications.

Cable Management

We carefully optimize the cable bend radius to ensure years of trouble-free operation. In the unlikely event of failure, Aerotech’s modular design makes cable replacement quick and easy with minimal downtime.

To facilitate integration into the final system, we include all customer-required cables, air hoses, etc. in our CMS bundle. Both ends are fully connectorized for simple integration into the customer’s machine.

Ordering Information

ABL8000 Air-Bearing Direct-Drive Linear Stage

| Option | Description |

| -0200 | 200 mm travel |

| -0300 | 300 mm travel |

| -0400 | 400 mm travel |

| -0500 | 500 mm travel |

| -0750 | 750 mm travel |

| -1000 | 1000 mm travel |

Carriage (Required)

| Option | Description |

| -SC | Short carriage - 250 mm length |

| -LC | Long carriage - 400 mm length |

- In an XY-assembled configuration, the -LC option is required for the lower (X) axis, and the -SC option with a maximum travel of 400 mm is required for the upper (Y) axis

Limits (Required)

| Option | Description |

| -Ll1 | Normally-closed, 5V end-of-travel limit switches |

| -Ll2 | Normally-open, 5V end-of-travel limit switches |

Feedback (Required)

| Option | Description |

| -E1 | Incremental linear encoder; 1 Vpp |

| -E2 | Incremental linear encoder; high accuracy, 1 Vpp |

Cable Management (Optional)

| Option | Description |

| -CMS1 | External cable management system for single axis |

| -CMS2 | External cable management system for single axis w/air/vac line |

| -CMS3 | External cable management system for single axis w/signal cable |

| -CMS4 | External cable management system for single axis w/air/vac line and signal cable |

| -CMS5 | External cable management system for lower-axis XY |

| -CMS6 | External cable management system for lower-axis of XY w/air/vac line |

| -CMS7 | External cable management system for lower-axis of XY w/signal cable |

| -CMS8 | External cable management system for lower-axis of XY w/air/vac line and signal cable |

Metrology (Required)

| Option | Description |

| -PL1 | Metrology, uncalibrated with performance plots |

| -PL2 | Metrology, calibrated (HALAR) with performance plots |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

Accessories (to be ordered as seperate line item)

| Option | Description |

| ABF | Air bearing filtration kit |