ANT180L Single-Axis Direct-Drive Nanopositioning Stage

ANT180L provides nanometer resolution, superior bi-directional repeatability and exceptional low-velocity performance, making it the ultimate solution for high-accuracy alignment, measurement, scanning and other demanding applications. Compared to ANT130L, ANT180L offers greater payload capacities and longer travel lengths.

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

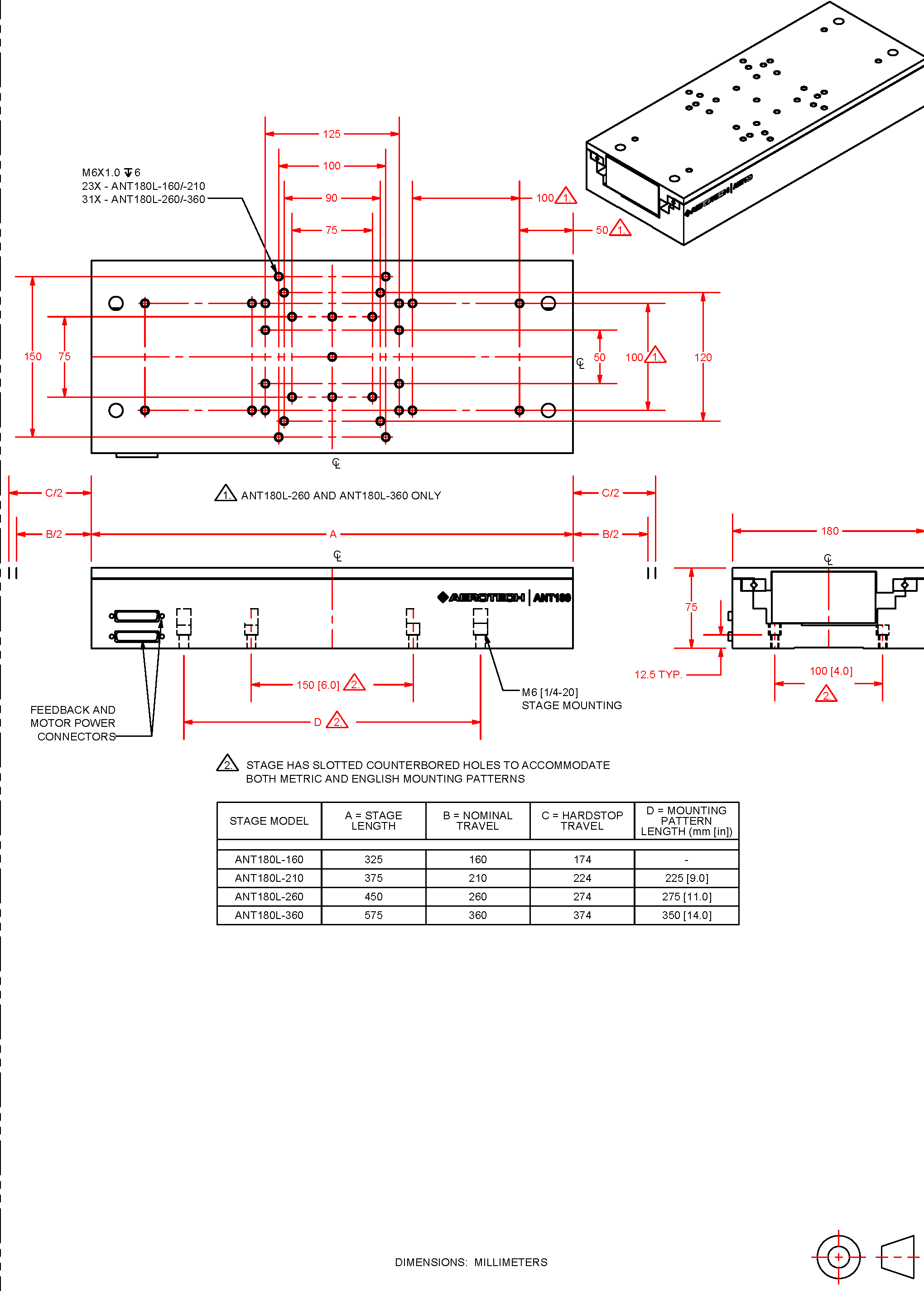

Dimensions

Ordering Info

Downloads

Description

Design Features

- Noncontact, non-cogging, frictionless direct-drive

- Zero backlash or hysteresis

- High resolution, repeatability and accuracy

- Anti-creep crossed-roller bearings

- Travel to 360 mm

- Integral cable management for multi-axis systems

Noncontact Direct-Drive

The ANT180L is driven by a high-power linear motor with ironless forcer and U-channel magnet track. The direct-drive linear motor drives the stage to a peak unloaded acceleration of 2 g and maximum velocity of 500 mm/s. Because the forcer is ironless, it is a cog-free design that provides exceptional velocity control.

Outstanding Resolution

The direct-drive linear motor and high-accuracy linear encoder make possible outstanding step-to-step resolution when coupled with an Aerotech control system. This is critical in spectroscopy, optical delay line and other applications. Furthermore, the linear motor and high resolution linear encoder system also provide excellent in-position stability.

Superior Geometry for High Performance

Its large cross-section provides a robust and stable base axis for multi-axis systems. Aerotech’s ultra-stiff construction and compact two-piece design result in a stage with unparalleled geometric tolerances. As a result, the straightness and flatness typically are <±1 μm over the entire travel.

Designed for smooth, vibration-free motion, the ANT180L utilizes precision anti-cage-creep crossed-roller bearings for outstanding smoothness of motion. Since neither the bearing system nor the drive system utilize any recirculating elements, the ANT180L exhibits the outstanding ripple-free motion required for scanning and inspection applications.

Precision Alignment and Cable Management

ANT180L series stages are easily configured into XY and other multi-axis assemblies. Precision orthogonality alignment to 5 arc seconds and multi-axis cable management systems (CMS) are standard options. We include all customer-required cables, air hoses, etc. in our CMS bundle to facilitate incorporation into the final system. Both ends are fully conne4torized for simple integration into the customer’s machine.

Ordering Information

Travel (Required)

| Option | Description |

| -160 | 160 mm travel stage |

| -210 | 210 mm travel stage |

| -260 | 260 mm travel stage |

| -360 | 360 mm travel stage |

Feedback (Required)

| Option | Description |

| -E1 | Incremental encoder, 1 Vpp |

| -E2 | Incremental encoder, 0.1 µm TTL output |

| -E3 | High-accuracy incremental encoder, 1 Vpp |

Cable Management (Optional)

| Option | Description |

| -CMS1 | Cable management system for XY assembly - order with lower-axis only |

| -CMS2 | Cable management system for XY assembly w/6 mm air line - order with lower-axis only |

| -CMS3 | Cable management system for XYZ assembly - order with lower-axis only |

| -CMS4 | Cable management system for XYZ assembly w/6 mm air line - order with lower-axis only |

| -CMS5 | Cable management system for XY assembly - order with upper-axis only |

| -CMS6 | Cable management system for XY assembly w/6 mm air line - order with upper-axis only |

| -CMS7 | Cable management system for XYZ assembly - order with upper-axis only |

| -CMS8 | Cable management system for XYZ assembly w/6 mm air line - order with upper-axis only |

Metrology (Required)

| Option | Description |

| -PL1 | Base performance |

| -PL2 | High-accuracy performance, PLUS |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

Accessories (to be ordered as separate line item)

| Option | Description |

| ALIGN-PA10 | XY assembly; 10 arc sec orthogonality |

| ALIGN-PA5 | XY assembly; 5 arc sec orthogonality |