ANT95L Single-Axis Linear Nanopositioning Stages

Our second-generation ANT95L linear stages are the leading solution for addressing your nanometer-level motion and positioning needs. Available in a variety of configurations, they’re best-in-class in combining resolution, accuracy, repeatability, size and reliability. Plus, with impressive dynamic capabilities and an enhanced load-carrying capacity, ANT95L stages are an excellent choice to amplify your process.

Description

Specifications

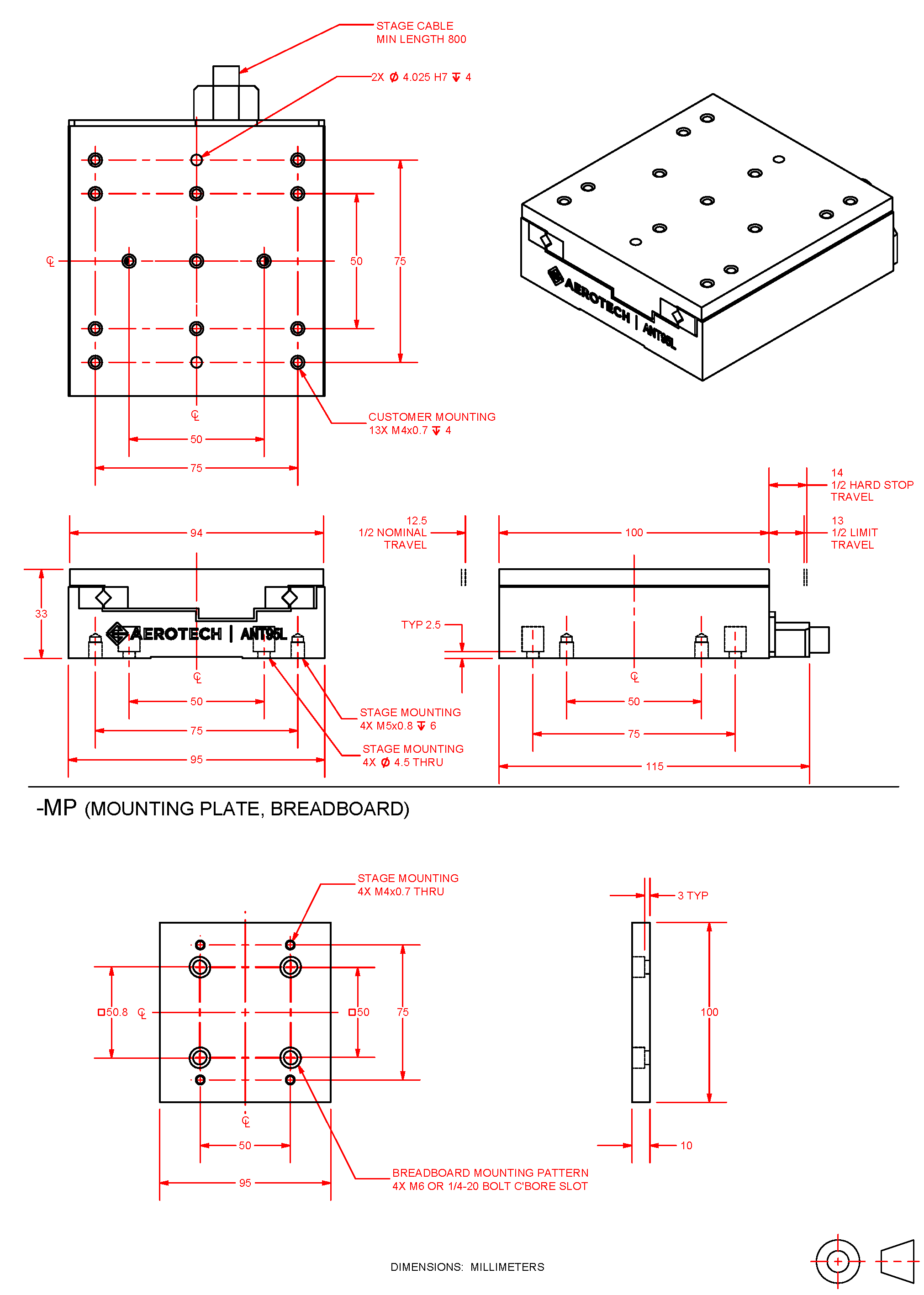

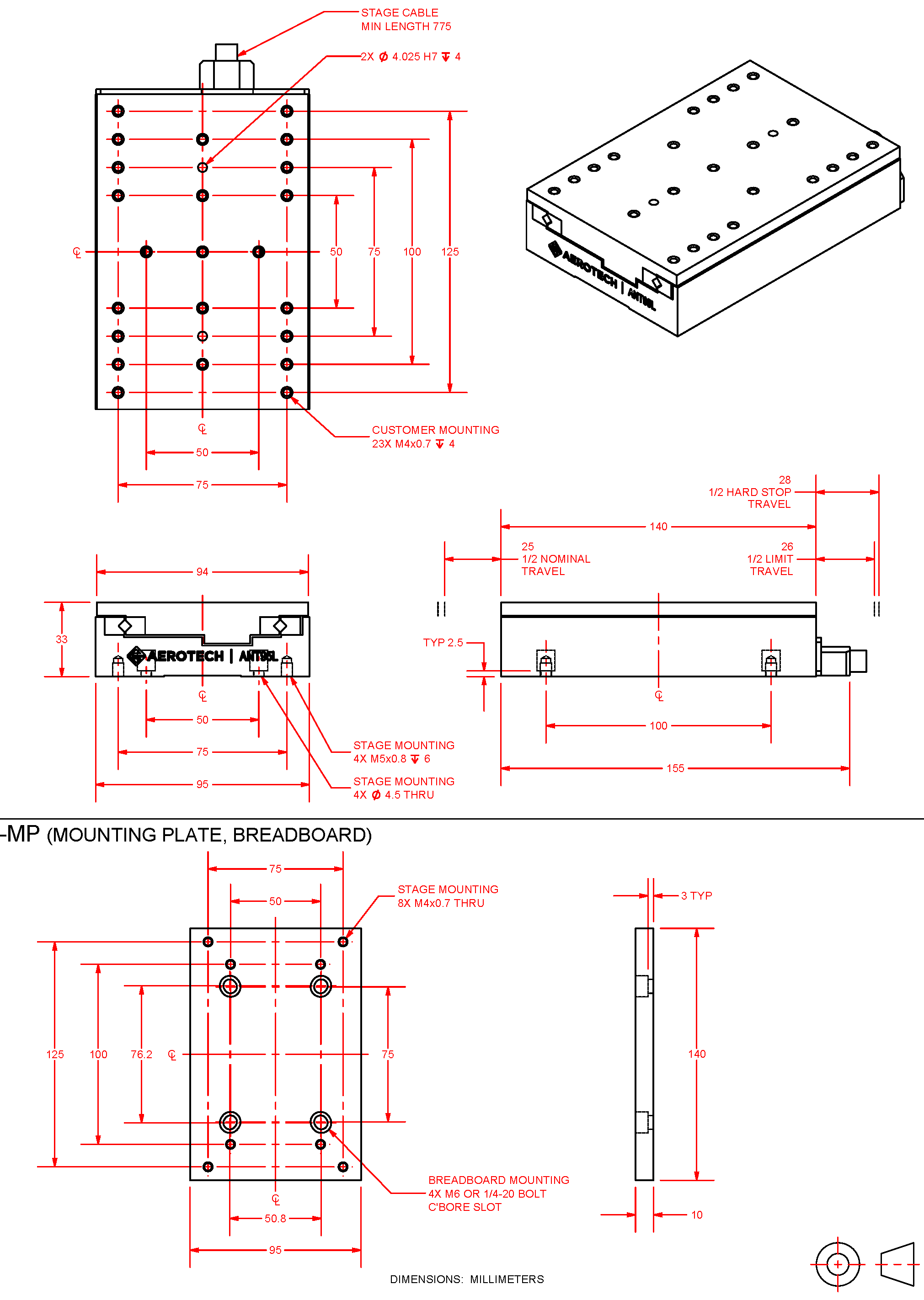

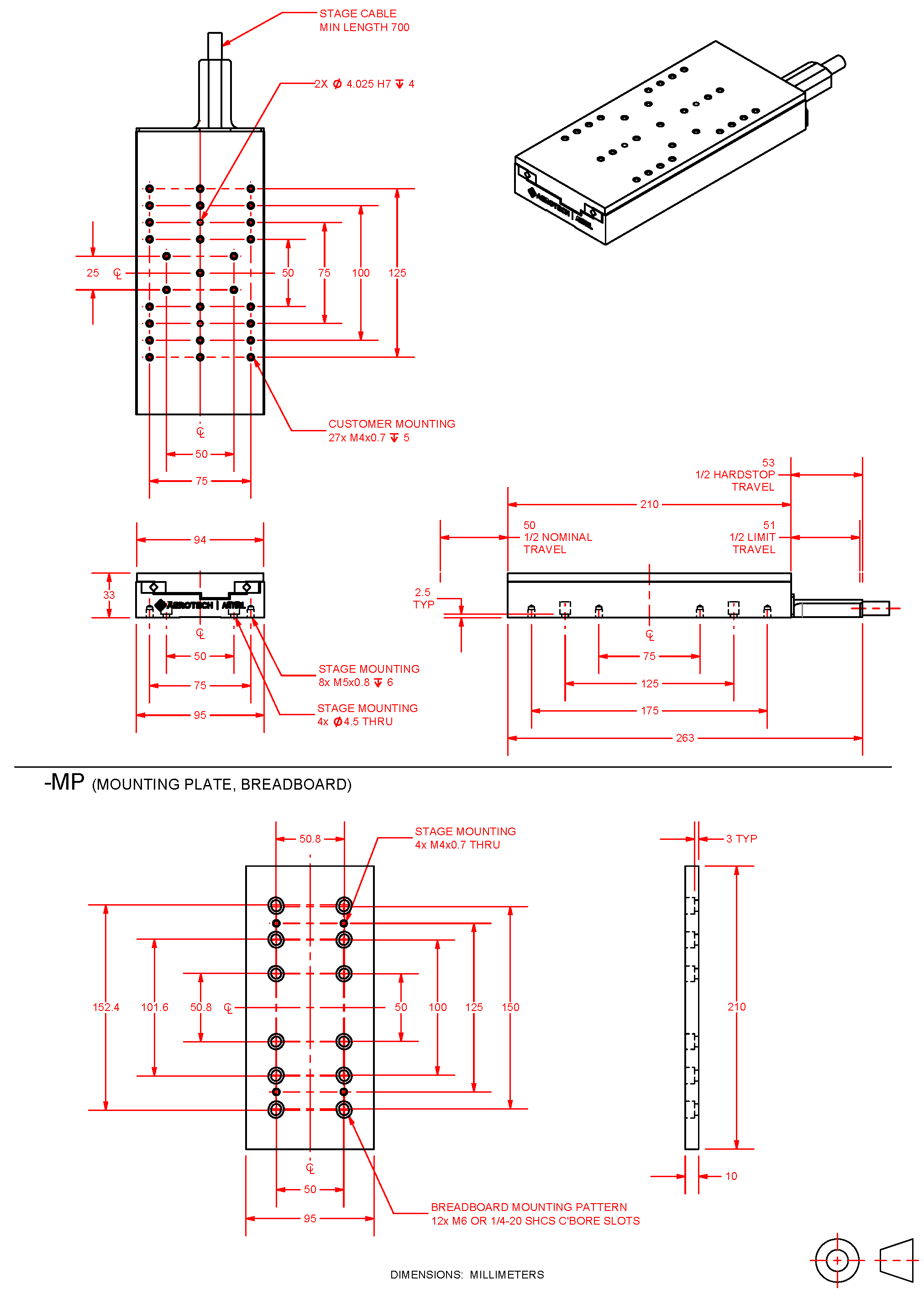

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Enhanced second-generation design

- Achieves minimum incremental motion to 0.5 nm - NEW

- Delivers nanometer-level positioning performance over travel lengths up to 100 mm

- Features high-precision crossed-roller bearings for excellent dynamic performance & generous load capacity

- Optimizes process throughput & maximizes reliability with ironless direct-drive linear motor

- Integrates easily into multi-axis assemblies & motion subsystems

- Available with high-resolution incremental or absolute encoders - NEW

Key Applications

ANT95L stages are ideal for high-precision and high-dynamic positioning applications, including:

- Photonics assembly & inspection

- Fiber alignment & optimization

- Optics manufacturing, testing & inspection

- Sensor testing & qualification

- Semiconductor processing & inspection

- Research & laboratory applications

Industry-Leading Motion Performance

Outstanding accuracy, position repeatability and in-position stability require extremely fine system resolution. Now available with an improved high-performance encoder option, ANT95L can easily achieve minimum incremental steps of 0.5 nm. Our direct-drive technology exhibits no hysteresis or backlash, enabling accurate and repeatable nanometer-scale motion.

Noncontact Direct-Drive

Only noncontact direct-drive technology offers the robust, accurate and high-speed positioning necessary for mass production of precision devices. ANT95L stages use our advanced direct-drive technology to achieve the highest level of positioning performance. This direct-drive technology delivers ultra-smooth, consistent motion with outstanding dynamic characteristics to optimize your process throughput. The unique drive and bearing combination, packaged in an extremely compact form factor, offers tangible advantages in many applications such as high-precision positioning, fiber alignment, optics manufacturing and inspection, sensor testing and scanning processes that demand smooth and precise motion.

Flexible System Design

The ANT95L family has universal mounting and tabletop patterns that allow for easy system integration. Two, three or more axes can be easily combined for flexible system designs and multi-axis configurations. Also available in an integrated XY arrangement, ANT95L stages are easily combined with other products — including ANT95LZ, ANT95LZS, ANT95R, ANT95V, ANT20G and more — to achieve complex, multiple degree-of-freedom motion and positioning solutions.

Ordering Information

Travel (Required)

| Option | Description |

| -025 | 25 mm travel |

| -050 | 50 mm travel |

| -100 | 100 mm travel |

- Other travel options are available upon request. Contact Aerotech for more information.

Feedback (Required)

Mounting Plate (Optional)

| Option | Description |

| -MP | Mounting plate |

Performance Grade (Required)

| Option | Description |

| -PL1 | Base performance |

| -PL2 | High-accuracy performance, PLUS |

Integration (Required)

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

- Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.