ATS150 Mechanical Bearing, Screw-Driven Linear Stage

ATS150 series ballscrew-driven linear stages provide the high resolution and repeatability required for semiconductor wafer testing and fabrication, automated microscope inspection systems and precision micromachining applications, and can be optionally configured with direct linear encoders for enhanced precision.

Description

Specifications

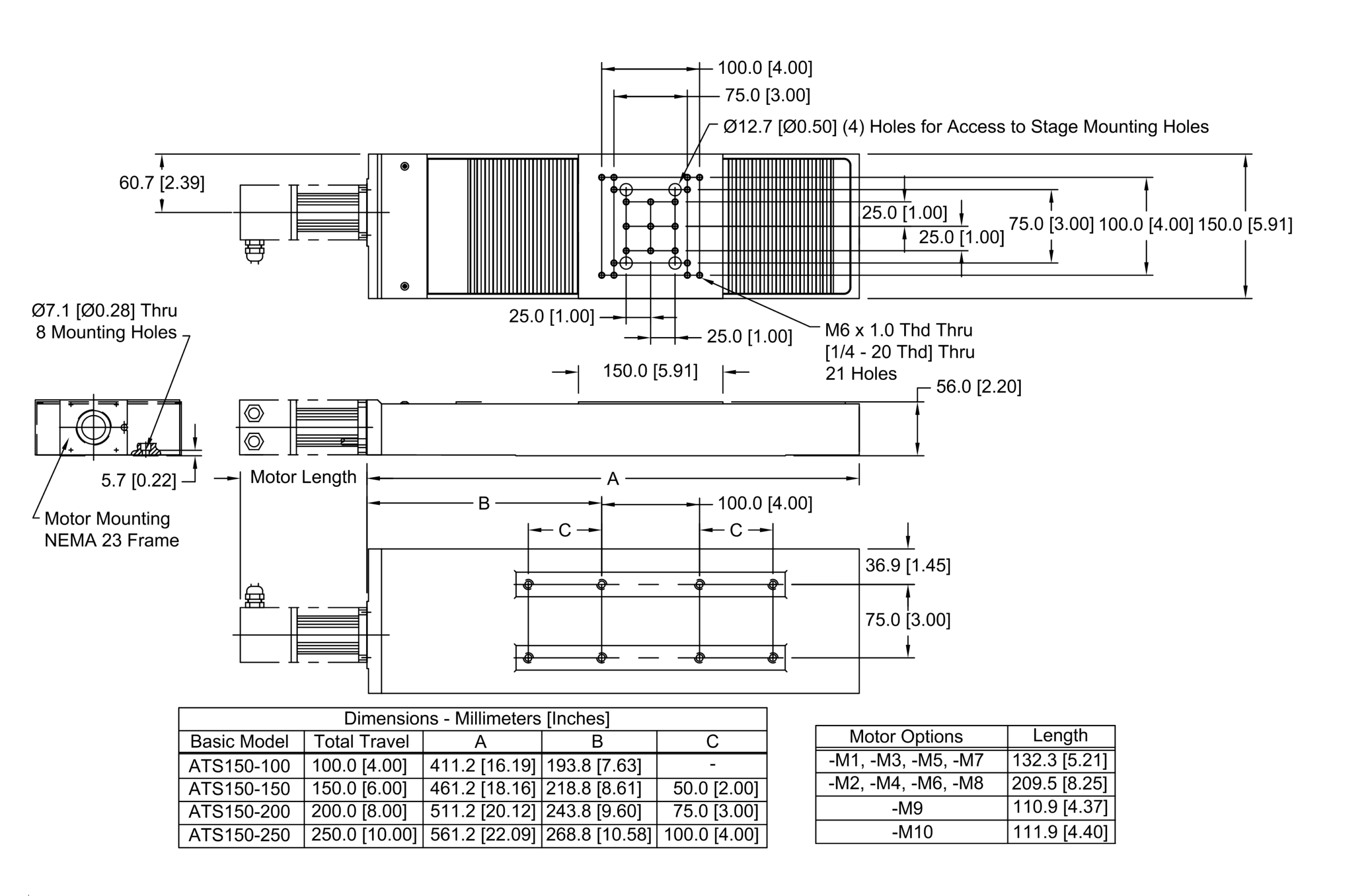

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Long life linear motion guide bearing system

- Ultra-fine resolution

- Integral bellows waycovers

- Low-profile compact design

- Submicron accuracy

- Optional high-accuracy linear encoder

Construction Features

ATS150 series stages are machined from a special cast aluminum alloy to provide a high strength-to-weight ratio and long-term stability. The base is a box design that provides exceptional stiffness and stability.

ATS150 series stages employ a precision-ground ball screw that is pre-loaded to eliminate backlash, and its nut has wipers to prevent contamination and maintain high accuracy throughout the life of the stage. High quality, pre-loaded duplex bearings are used to eliminate axial play.

All ATS150 series stages incorporate Linear Motion Guide (LMG) bearings to provide high load capability and high stiffness. The LMG design provides a compact stage with continuous carriage support over the entire travel and good cantilevered load capability. Integral wipers on the bearing trucks help ensure stage travel life. Highly accurate optical limit switches and end stops are also standard.

Integral bellows-type waycovers protect the drive and bearing system from contamination. Metal surfaces are protected with an attractive clear anodized finish. Both metric (standard) and English mounting and bolt-hole patterns are available.

Linear Encoder

A precision noncontact linear encoder is an option. The encoder is mounted internal to the stage, protecting it from external contaminants and debris.

Motors and Drives

Included with all ATS150 series stages are Aerotech’s BMS series brushless rotary motors. This motor has all of the advantages of a brushless motor – high acceleration, no brushes to wear and lower heating – yet has zero cogging for extremely smooth motion and accuracy. Aerotech manufactures a wide range of matching drives and controls to provide a fully integrated and optimized motion solution.

Ordering Information

ATS150 Series Mechanical-Bearing Screw-Driven Linear Stage

Travel (Required)

| Option | Description |

| -100 | 100 mm |

| -150 | 150 mm |

| -200 | 200 mm |

| -250 | 250 mm |

Vacuum Preparation (Required)

| Option | Description |

| -HV | High vacuum preparation to 10-6 Torr |

Direct Linear Feedback (Required)

| Option | Description |

| -E1 | High-accuracy incremental linear encoder; 1 Vpp |

- Linear encoder option only available on the 100 mm and 150 mm travels

Tabletop (Required)

| Option | Description |

| -TT1 | Tabletop with metric dimension mounting pattern and holes |

| -TT2 | Tabletop with English dimension mounting pattern and holes |

Ball Screw (Required)

| Option | Description |

| -BS1 | 2mm/rev precision-ground ball screw |

Motor (Optional)

| Option | Description |

| -M1 | BMS60 servomotor w/2500-line TTL encoder |

| -M2 | BMS60 servomotor w/2500-line TTL encoder and holding brake |

| -M3 | BMS60 servomotor w/1000-line 1 Vpp |

| -M4 | BMS60 servomotor w/1000-line 1 Vpp encoder and holding brake |

| -M5 | BM75 servomotor w/2500-line TTL encoder |

| -M6 | BM75 servomotor w/2500-line TTL encoder and holding brake |

| -M7 | BM75 servomotor w/1000-line 1 Vpp encoder |

| -M8 | BM75 servomotor w/1000-line 1 Vpp encoder and holding brake |

| -M9 | SM60 stepper motor, SM60-CN1-VT2 |

| -M10 | SM60 stepper motor w/holding brake, SM60-CN1-VT2-BK |

Foldback (Optional)

| Option | Description |

| -FB1 | Foldback kit for .250 inch diameter shaft NEMA 23 motor |

| -FB2 | Foldback kit w/brake for .250 inch diameter shaft NEMA 23 motor |

Motor Orientation (Optional)

| Option | Description |

| -2 | Bottom cable exit, optional orientation |

| -3 | Left-side cable exit, standard orientation |

| -4 | Top cable exit, optional orientation |

| -5 | Right-side cable exit, optional orientation |

| -8 | Right-side foldback, standard orientation |

| -12 | Left-side foldback, optional orientation |

Limits (Required)

| Option | Description |

| -Ll1 | Normally-closed limit switches; 9-pin D connector |

| -Ll2 | Normally-closed limit switches; flying leads |

| -Ll3 | Normally-open limit switches; 9-pin D connector |

| -Ll4 | Normally-open limit switches; flying leads |

Coupling (Optional)

| Option | Description |

| -CP1 | Coupling for 0.250 inch diameter shaft |

| -CP2 | Coupling for 0.375 inch diameter shaft |

Metrology (Optional)

| Option | Description |

| -PL1 | Metrology, uncalibrated with performance plots |

| -PL2 | Metrology, calibrated (HALAR) performance plots |

Metrology -HALSF (Optional)

| Option | Description |

| -PL5 | Metrology, horizontal/vertical straightness correction (HALSF) |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

Accessories (to be ordered as a separate line item)

| Option | Description |

| ALIGN-NPA | Non-precision XY assembly |

| ALIGN-NPAZ | Non-precision XZ or YZ assembly |

| ALIGN-PA10 | XY assembly; 10 arc sec orthogonality. Alignment to within 7 microns orthogonality for short travel stages. |

| ALIGN-PA10Z | XZ or YZ assembly with L-bracket; 10 arc second orthogonality. Alignment to within 10 microns orthogonality for short travel stages. |

| ALIGN-PA5 | XY assembly; 5 arc sec orthogonality. Alignment to within 3 microns orthogonality for short travel stages. |

| ALIGN-PA5Z | XZ or YZ assembly with L-bracket; 5 arc second orthogonality. Alignment to within 5 microns orthogonality for short travel stages. |

| HDZ2 | English right angle L-bracket; for ATS150-100 and ATS150-150 only |

| HDZ2M | Metric right angle L-bracket; for ATS150-100 and ATS150-150 only |