ANT130XY Two-Axis XY Nanopositioning Stages

Our ultra-precise ANT130XY stages deliver superior planar performance with excellent geometric characteristics, thanks to an integrated two-axis design. Equipped with stiff, anti-creep crossed-roller bearings, high-resolution position feedback and ironless linear motors to achieve the smoothest, most precise motion possible, ANT130XY stages can be further enhanced with ultra high-accuracy 2D calibration to optimize even the most demanding inspection and manufacturing processes. Plus, the dynamically optimized design results in impressive speed and process throughput.

Description

Specifications

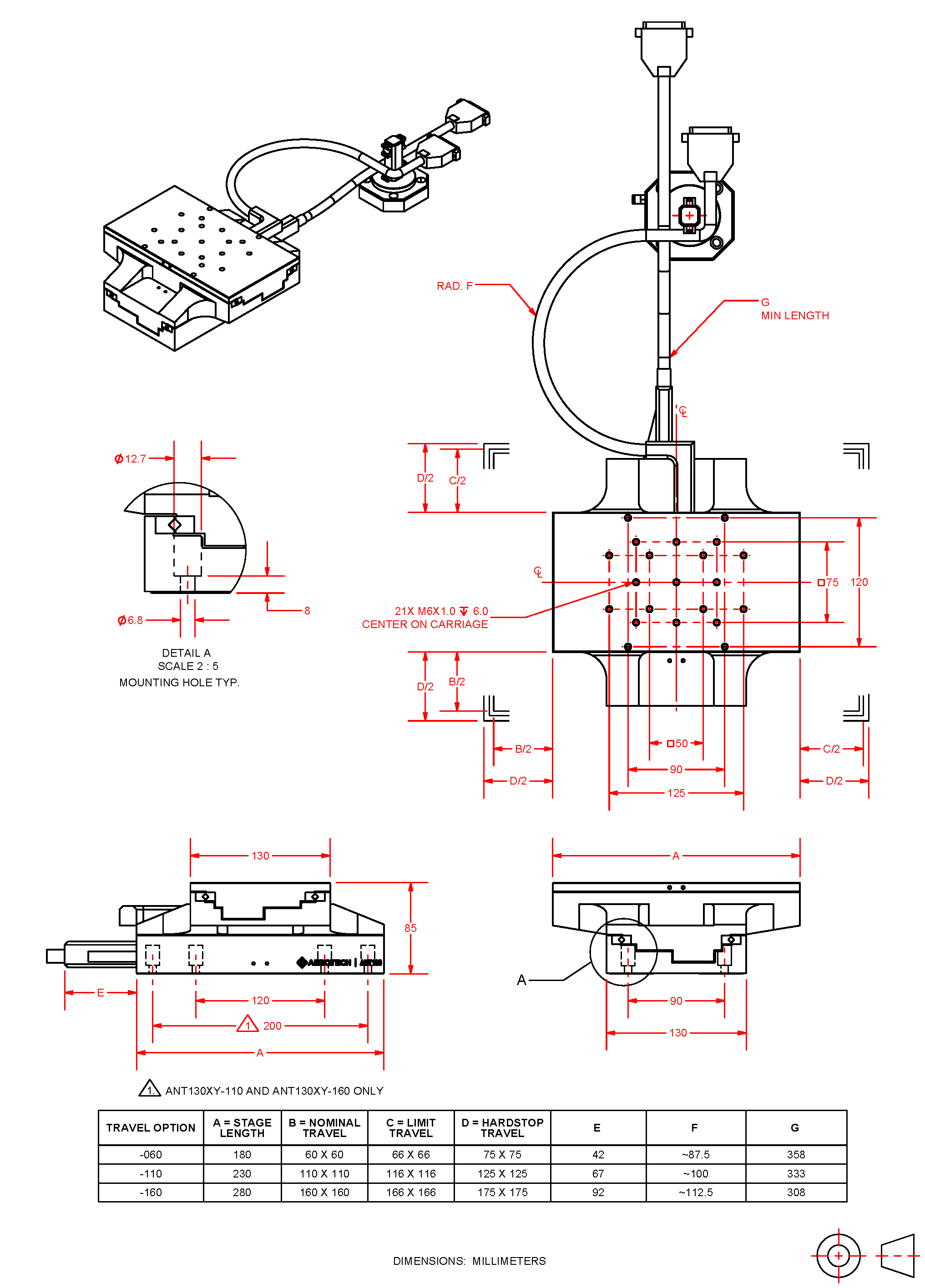

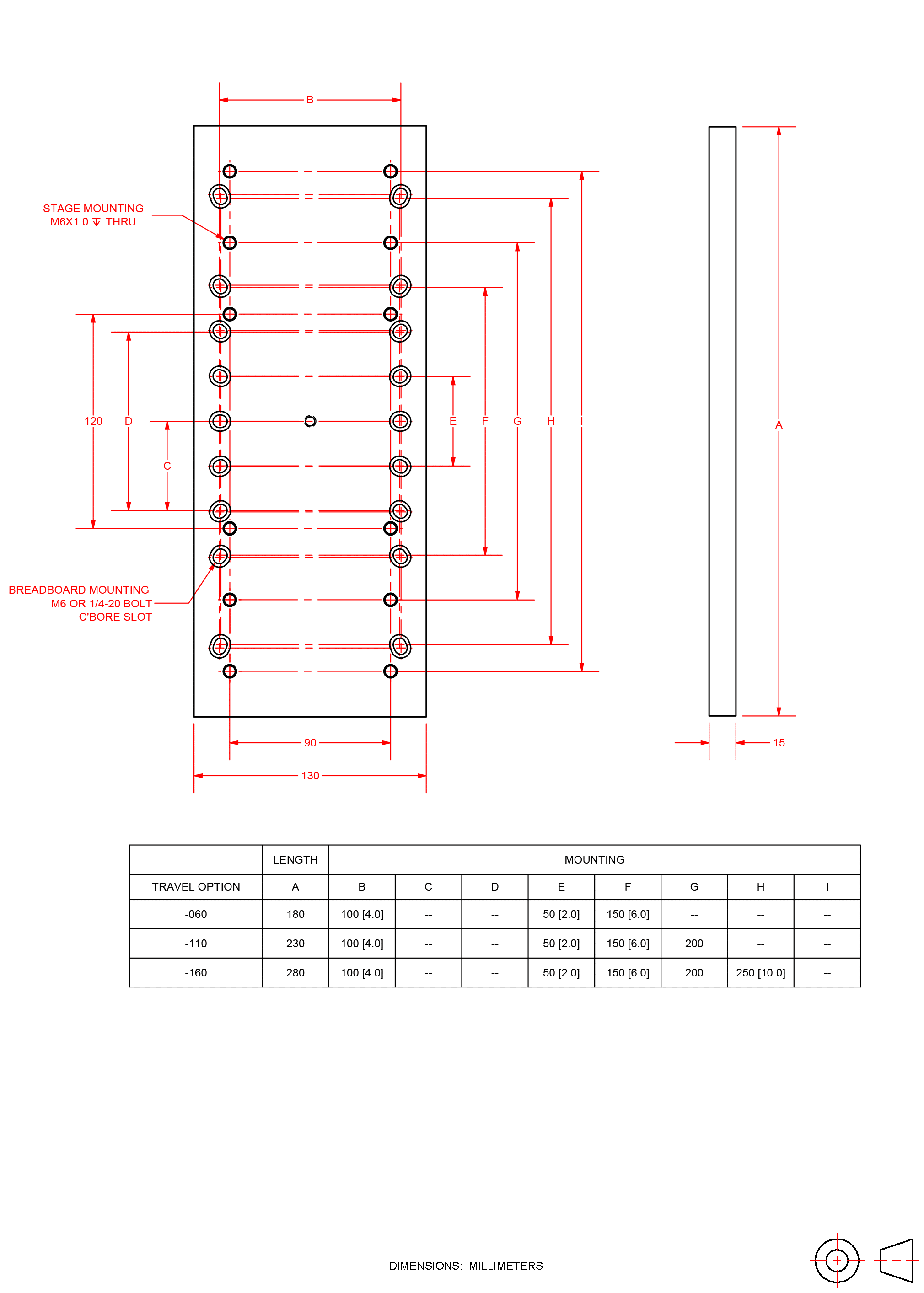

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Enhanced second-generation design

- Achieves minimum incremental motion to 0.5 nm - NEW

- Optimizes orthogonality, straightness & flatness with integrated XY design

- Guarantees two-dimensional accuracy of ±225 nm or better with ULTRA calibration option

- Features high-precision crossed-roller bearings for excellent dynamic performance & ample load capacity

- Maximizes process throughput & reliability with ironless direct-drive linear motor

- Available with high-resolution incremental or absolute encoders - NEW

Key Applications

ANT130XY is ideal for multi-axis applications that require high precision and dynamic positioning performance, including:

- Photonics assembly & inspection

- Fiber alignment & optimization

- Optics manufacturing, testing & inspection

- Sensor testing & qualification

- Semiconductor processing & inspection

- Surface metrology & profilometry

- Research & laboratory applications

Ultra-Precise Stage Design

ANT130XY’s integrated two-axis design allows you to optimize critical geometric elements such as orthogonality, straightness and flatness, resulting in a stage with exceptional motion characteristics. Our direct-drive technology has no hysteresis or backlash, enabling accurate and repeatable nanometer-scale motion in both the X and Y dimensions. ANT130XY is available in three travel options ranging from 60 mm x 60 mm to 160 mm x 160 mm, all featuring a compact overall height of 85 mm.

Noncontact Direct-Drive

Only noncontact direct-drive technology offers the robust, accurate and high-speed positioning necessary for mass production of precision devices. ANT130XY stages use our advanced direct-drive technology to achieve the highest level of positioning performance. Coupled with anti-creep, crossed-roller bearings, ANT130XY delivers ultra-smooth, consistent motion with outstanding dynamic characteristics to enhance your process capability. The optimized drive and bearing combination, packaged in a compact form factor, offers distinct performance advantages in many applications such as high-precision positioning, fiber alignment, optics manufacturing and inspection, sensor testing and scanning processes that demand smooth and precise motion.

Flexible System Design

The ANT130XY family has universal mounting and tabletop patterns that allow for easy system integration. ANT130XY stages are easily combined with other products -- including ANT130LZ, ANT130R, ANT130V, ANT20G and more -- to provide complex, multiple degree-of-freedom motion and positioning solutions.

ULTRA Performance Grade Option

In order to achieve the highest possible system accuracy from our multi-axis nanopositioning systems, we’ve developed an advanced, dynamic trajectory calibration system. To take advantage of this sophisticated calibration system, the mechanical system is completely assembled, functionally tested and calibrated in our best-in-class metrology labs. Nanometer-level system accuracy can only be achieved under stringent environmental conditions that ensure calibration with the best test equipment, using the highest-precision mechanical elements and ULTRA software capabilities of our industry-leading controls. By implementing ULTRA dynamic trajectory calibration with the ANT130XY, we are able to produce guaranteed two-dimensional accuracies of ±225 nm or better.

The plots provided in the specifications illustrate performance differences between a standard ANT130XY and the ULTRA version. ULTRA calibration virtually eliminates straightness, orthogonality and accuracy errors resulting from yaw.

Ordering Information

ANT130XY Two-Axis XY Nanopositioning Stage

Travel (Required)

| Option | Description |

| -060 | 60 mm x 60 mm travel |

| -110 | 110 mm x 110 mm travel |

| -160 | 160 mm x 160 mm travel |

Feedback (Required)

| Option | Description |

| -E1 | Incremental linear encoders, 1 Vpp amplified sine output |

| -E2 | Incremental linear encoders, digital RS422 output, 5 nm electrical resolution |

| -E3 | Absolute + Incremental 1 Vpp linear dual-track encoder |

| -E4 | Incremental linear encoders, 1 Vpp amplified sine output, high-performance |

Connectors (Required)

| Option | Description |

| -CN1 | Single 25-pin D connector, 25DU |

| -CN2 | Two connector, 4-pin HPD and 25-pin D, 4DU-25DU |

- The -CN1 option is limited to a maximum bus voltage of 80 V. The -CN2 option is required for higher bus voltages.

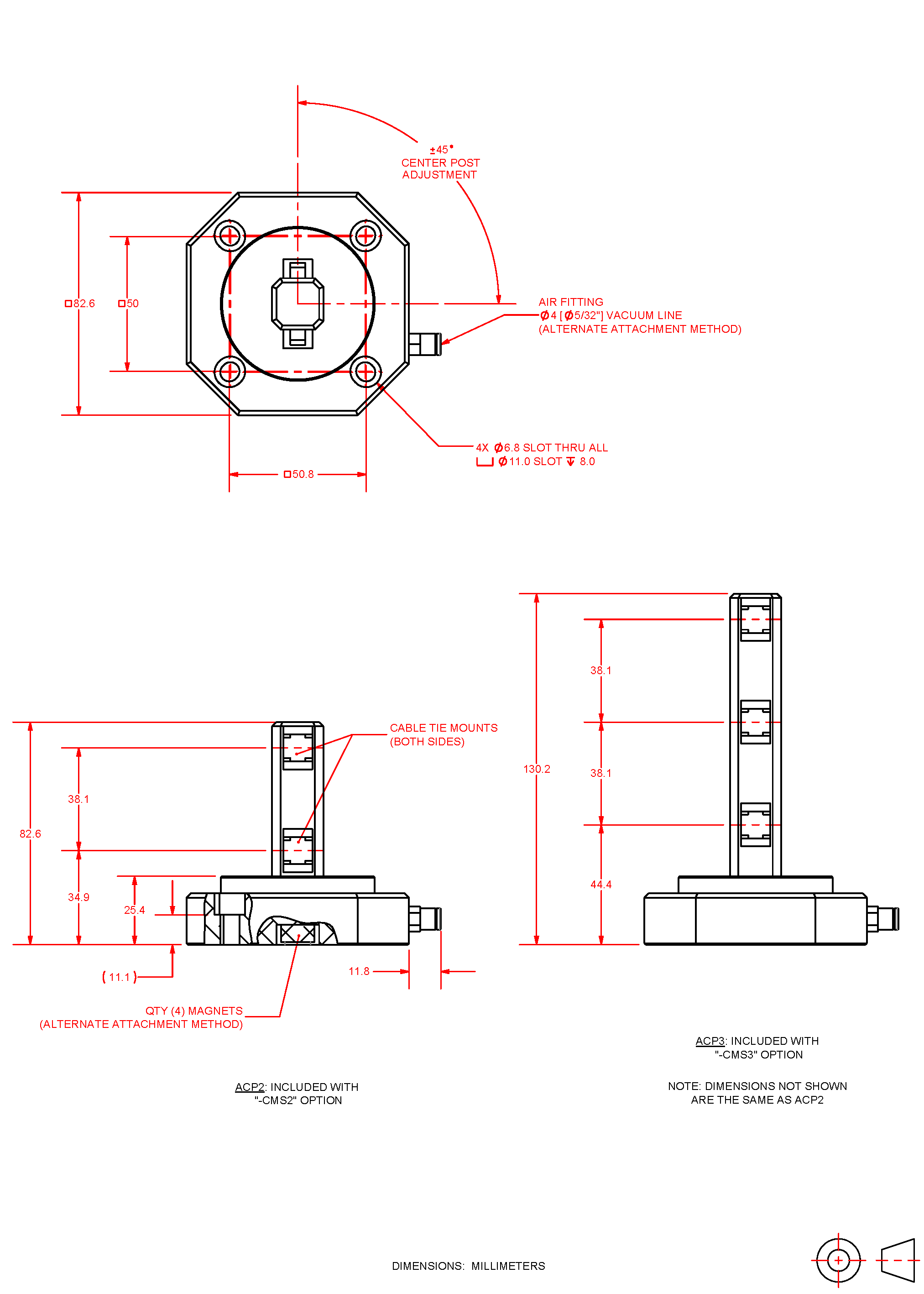

Cable Management (Required)

| Option | Description |

| -CMS2 | Post for two-axis cable support |

| -CMS3 | Post for three-axis cable support |

Mounting Plate (Optional)

| Option | Description |

| -MP | Mounting plate |

Performance Grade (Required)

| Option | Description |

| -PL1 | Base performance |

| -PL3 | High-accuracy performance, PLUS |

| -PL4 | Ultra high-accuracy performance, ULTRA |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |