ADRS Mechanical-Bearing Direct-Drive Rotary Stage

ADRS stages combine direct-drive brushless technology with a low profile to increase throughput and minimize “stack-up” errors at your work point. Because they achieve quicker acceleration and higher top speeds than gear- or belt-driven mechanisms, ADRS stages yield higher overall throughput. Plus, with no brushes to replace and no gear trains or belts to maintain, they’re optimized for 24/7 production environments and result in lower total cost of ownership.

Description

Specifications

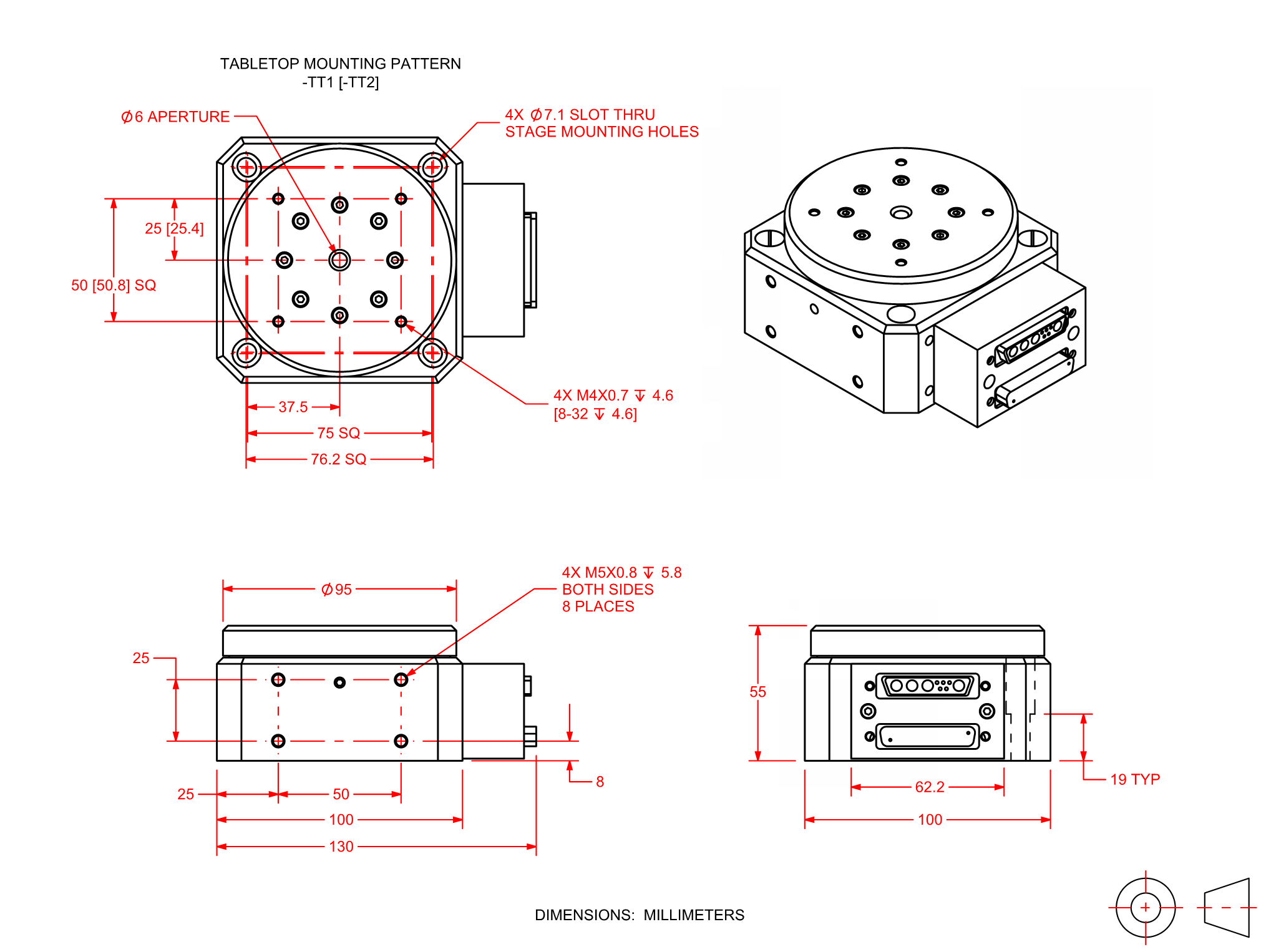

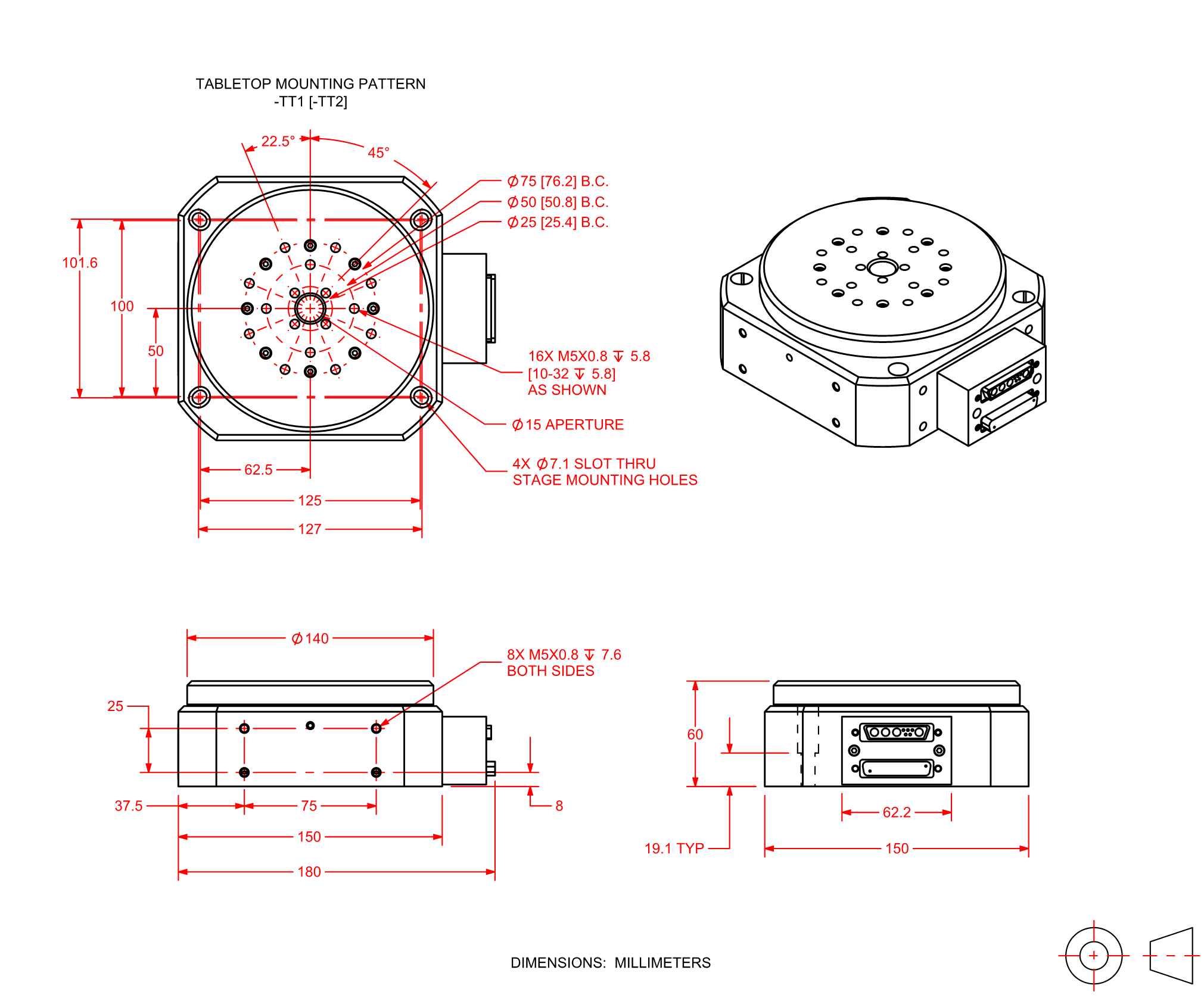

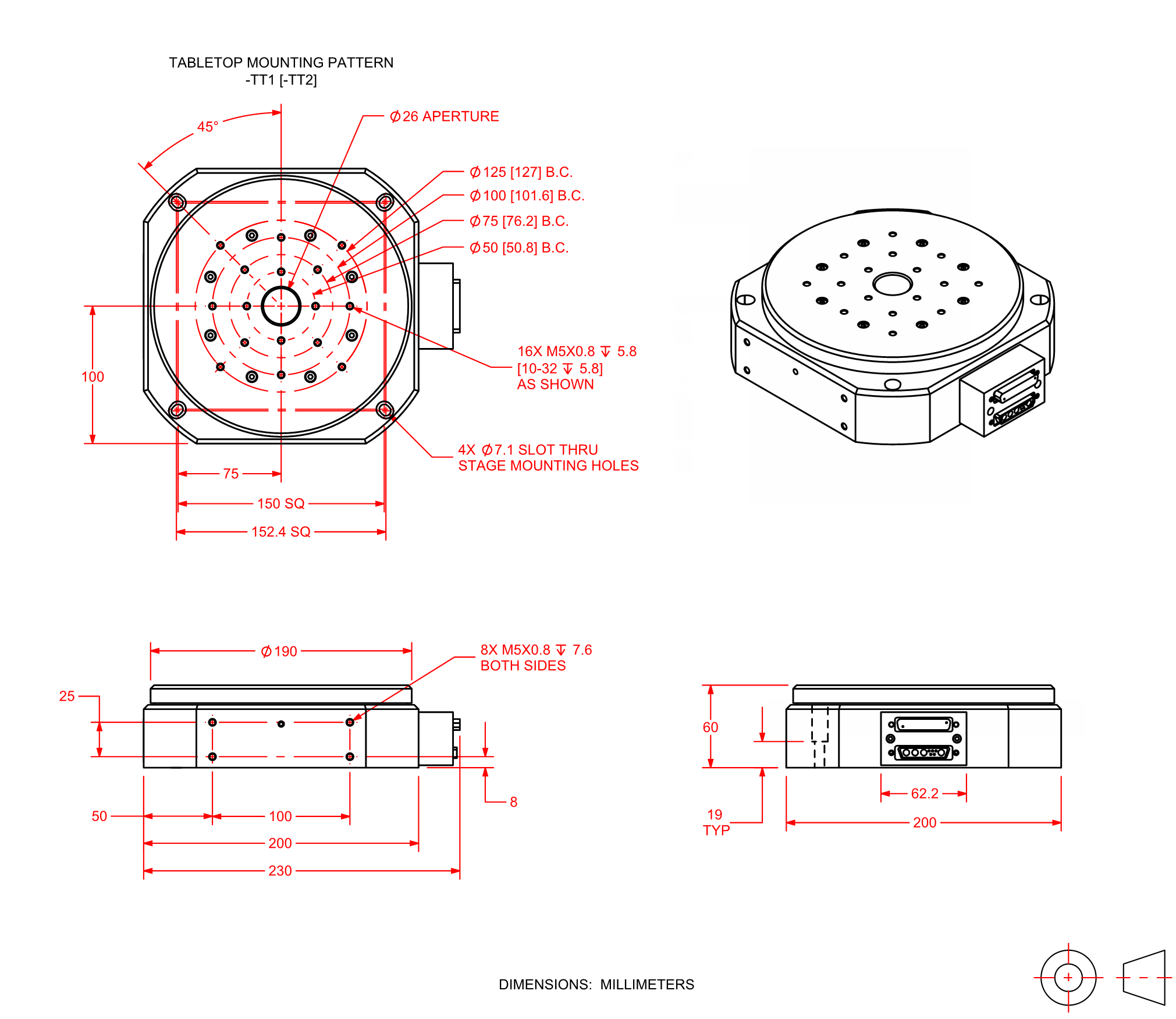

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Maximizes positioning performance with direct-drive brushless motor technology

- Delivers high-torque output

- Offers outstanding velocity stability due to cog-free slotless motor design

- Uses direct coupled, high-accuracy rotary encoder

- Yields high throughput and low total cost of ownership

- Provides a clear aperture that can be used for product feed-through or laser beam delivery

- Minimizes working height

- Designed for 24/7 production environments that required precise, low-maintenance components

Key Applications

ADRS is ideal for 24/7 production environments that required precise, low-maintenance components, including:

- Rotary indexing and alignment

- Precision testing, measurement and inspection

- Sensor testing

- Semiconductor wafer processing

- Precision manufacturing and automation

- Laser microprocessing

Superior Alternative to Belt- and Worm-Drive Stages

Aerotech’s ADRS series combines direct-drive brushless technology with a low profile to increase throughput and minimize “stack-up” related errors at your work point. With no brushes to replace and no gear trains or belts to maintain, direct-drive technology is optimized for 24/7 production environments. It provides quicker acceleration and higher top speeds than gear- or belt-driven mechanisms, yielding higher total overall throughput. The low-maintenance and high-performance characteristics of the ADRS series result in a lower total cost of ownership.

Multiple Configurations to Meet Your Needs

The ADRS series is available in 100 mm, 150 mm and 200 mm versions and can be configured with a variety of encoder options for high-precision position feedback. Alternate motor windings provide the flexibility to achieve either low-current or low-voltage operation at a given speed.

Metric and English pattern tabletops are available, and slotted mounting holes enable attachment to 25 mm and 1-inch hole pattern breadboards. Tabletops also feature a labyrinth seal to protect the bearings and encoder from contamination. Add an optional lower seal to the shaft for applications where the bottom of the stage is exposed to contamination.

Ordering Information

ADRS Mechanical-Bearing Direct-Drive Rotary Stage

Feedback (Required)

| Option | Description |

| -E6 | Incremental encoder, 1 Vpp |

| -E10 | Incremental Encoder, digital RS422, electrical resolution 1.02 arc sec (ADRS100) or 0.65 arc sec (ADRS150, ADRS200) |

- Other feedback options are available upon request. Contact Aerotech for more information.

Motor (Required)

| Option | Description |

| -M1 | Low current, -A winding |

- Other motor options are available upon request. Contact Aerotech for more information.

Tabletop (Required)

| Option | Description |

| -TT1 | Metric tabletop |

- Other tabletop options are available upon request. Contact Aerotech for more information.

Lower Seal (Optional)

| Option | Description |

| -SL | Rear seal |

Metrology (Required)

| Option | Description |

| -PL1 | Metrology, uncalibrated with performance plots |

| -PL2 | Metrology, calibrated (HALAR) with performance plots |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |