ASR1200 Mechanical-Bearing Direct-Drive Rotary Collet Stage

Our ASR1200 series is an extension of the ASR1000 direct-drive rotary stage. The ASR1200 adds an integral pneumatically-operated collet chuck for automated material handling and a sealed water jacket for wet cutting processes.

Description

Specifications

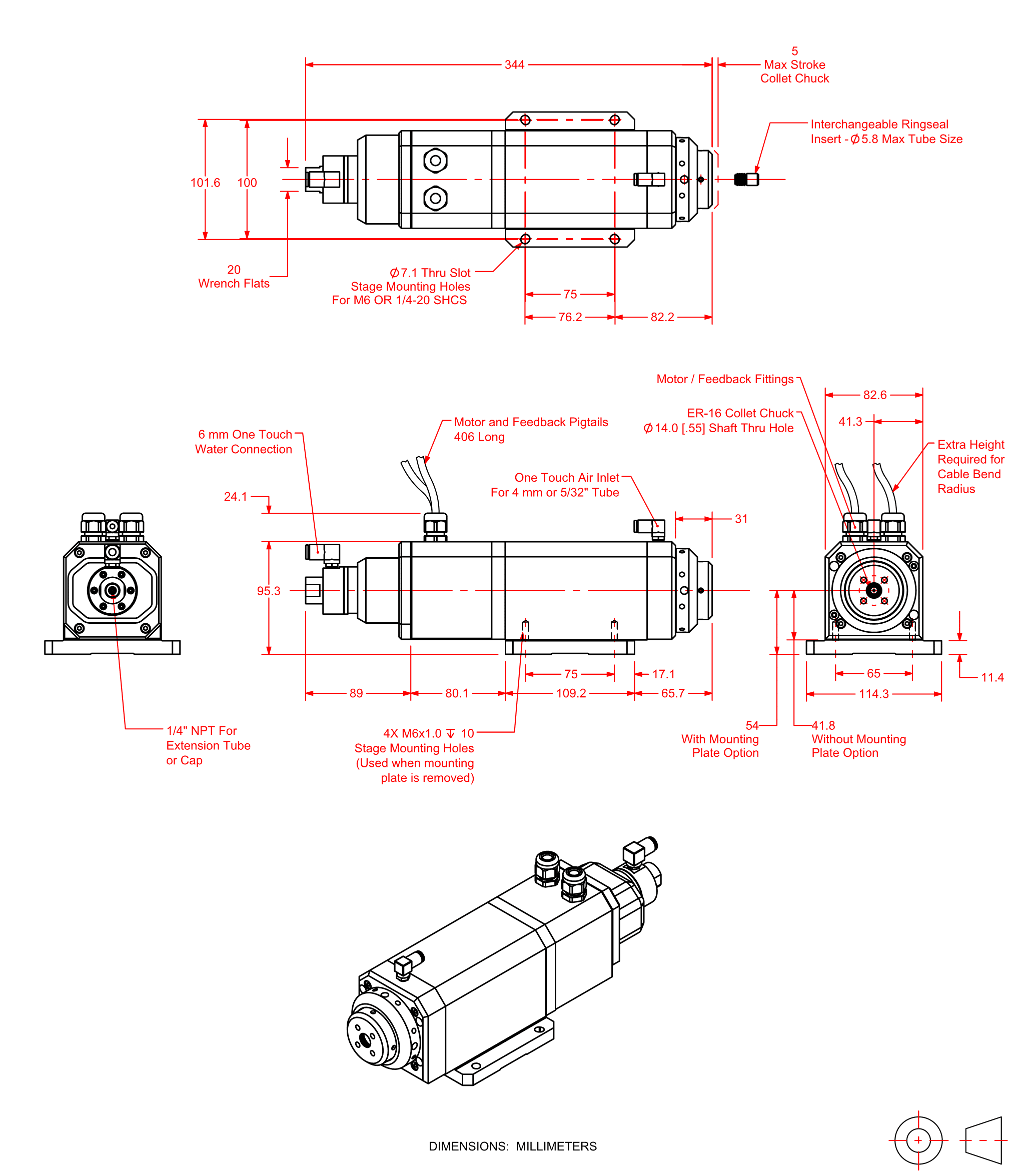

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- ER16 collet accepts up to 5.8 mm O.D. tubing

- Integral water jacket with scalable O-ring seal for wet cutting applications

- Clear aperture for product feed-through

- Threaded collet retainer enables rapid tooling changeover

- Low inertia shaft for maximum acceleration

- Direct-drive brushless motor and encoder

- Maintenance-free frictionless rotary union

- High-speed (2000 rpm) and standard-speed (800 rpm) options

Integral Collet Design

The collet chuck on the ASR1200 accepts ER161 series collets. These collets are readily available in sizes that support tube diameters from 0.5 mm to 5.8 mm. The collet is retained with a threaded retaining cap that enables quick changeover. The collet is configured in a "fail-safe" mode where full clamping force is applied when no air pressure is present. Air is delivered to the rotating collet assembly through a custom-designed frictionless, seal-less rotary union. This 100% noncontact rotary union design ensures a lifetime of maintenance-free operation. The combination collet chuck and rotary union also has significantly less friction and inertia than external assemblies created from discrete parts. This reduced inertia improves system performance by allowing higher peak acceleration and reducing position error during laser machining operations.

Fluid Delivery System

The ASR1200 includes a fluid delivery system and seal assembly to support wet cutting processes. The rear of the unit has a quick release fitting for fluid input and an NPT thread that allows the user to customize the length of the "water jacket" to match the length of the tube material. Inside the ASR1200 is an O-ring assembly that seals the tubing against the I.D. of the ASR1200 shaft. This seal assembly rotates with the tubing, eliminating troublesome torsion-induced errors that are present when working with thin-walled tubing or extremely flexible materials such as Nitinol.

Direct Drive

The ASR1200 series utilizes direct-drive brushless motor technology to maximize positioning performance. Direct-drive technology is optimized for 24/7 production environments because there are no brushes to replace and no gear trains or belts to maintain. Direct drive also provides quicker acceleration and higher top speeds than gear- or belt-driven mechanisms yielding higher total overall throughput.

The low maintenance and high throughput characteristics of the ASR1200 provide a stage that yields the lowest total cost of ownership while the integral water jacket and pneumatic collet provide unmatched levels of integration and ease of use.

1. Requires Rego-Fix electropolished collet. ER16 supports up to 10 mm. Actual tube diameter is limited by fluid delivery system.

Ordering Information

ASR1200 Mechanical-Bearing Direct-Drive Rotary Collect Stage

| Option | Description |

Speed (Required)

| Option | Description |

| -SS | Standard speed |

| -HS | High speed |

Connector (Required)

| Option | Description |

| -CN1 | 4-pin HPD motor and 25-pin D feedback connectors |

| -CN2 | 25-pin D motor and 25-pin D feedback connectors |

Mounting Plate (Optional)

| Option | Description |

| -MP | Mounting plate |

Wrench (Optional)

| Option | Description |

| WR | Wrench for changing collet |

Integration (Required)

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

Accessories (to be ordered as a separate line item)

| Option | Description |

| Collet-ER16-CLTxx | ER16 DIN6499AA electropolished collet, 0.5 mm to 10 mm part diameter sizes available |

| CGF | Collet and gripper filtration kit |