CCS Mechanical-Bearing Direct-Drive Rotary Collet Stage

Our CCS series rotary stages with integrated captured collet chucks provide automated material handling capability for a wide range of materials and applications.

Description

Specifications

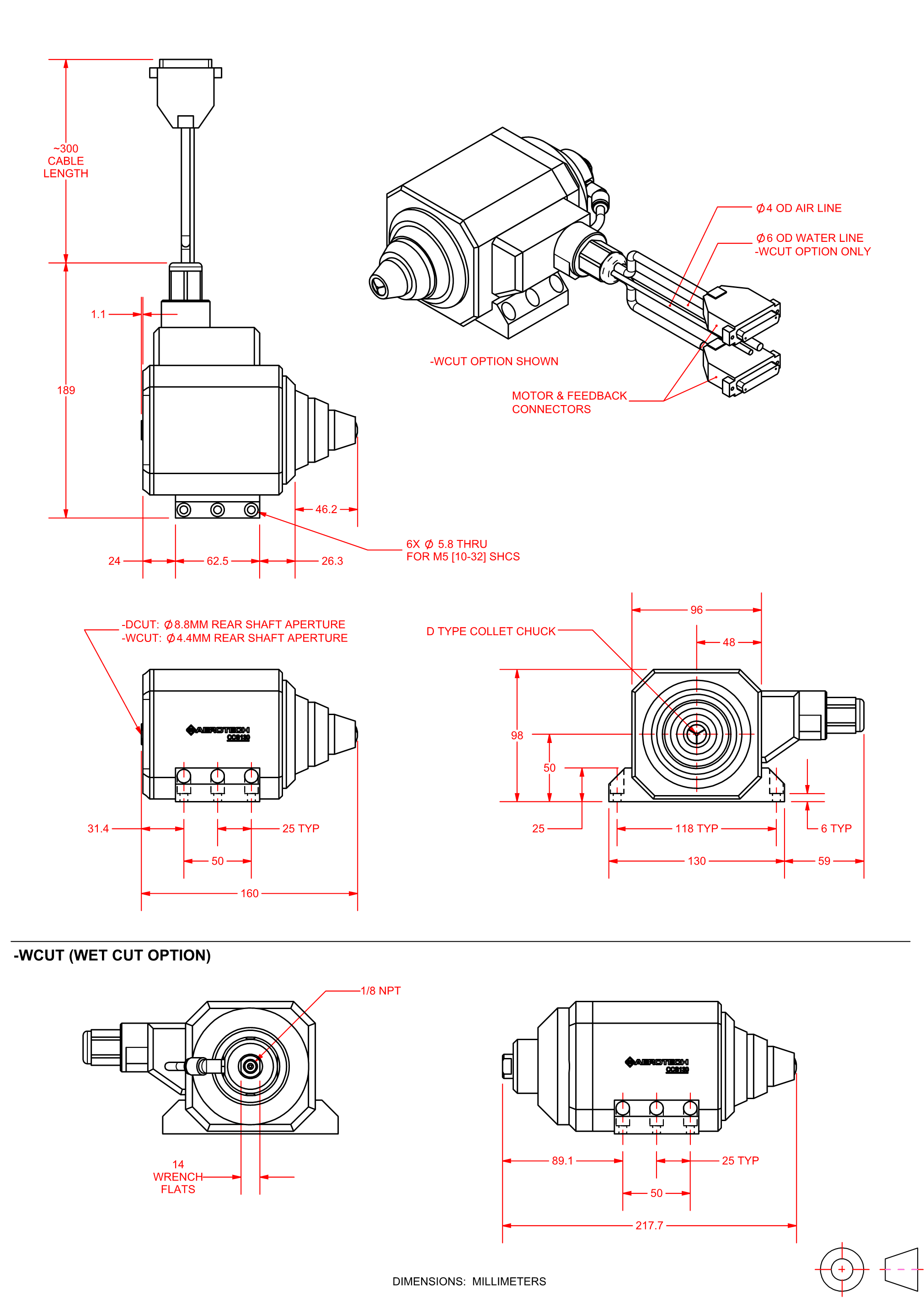

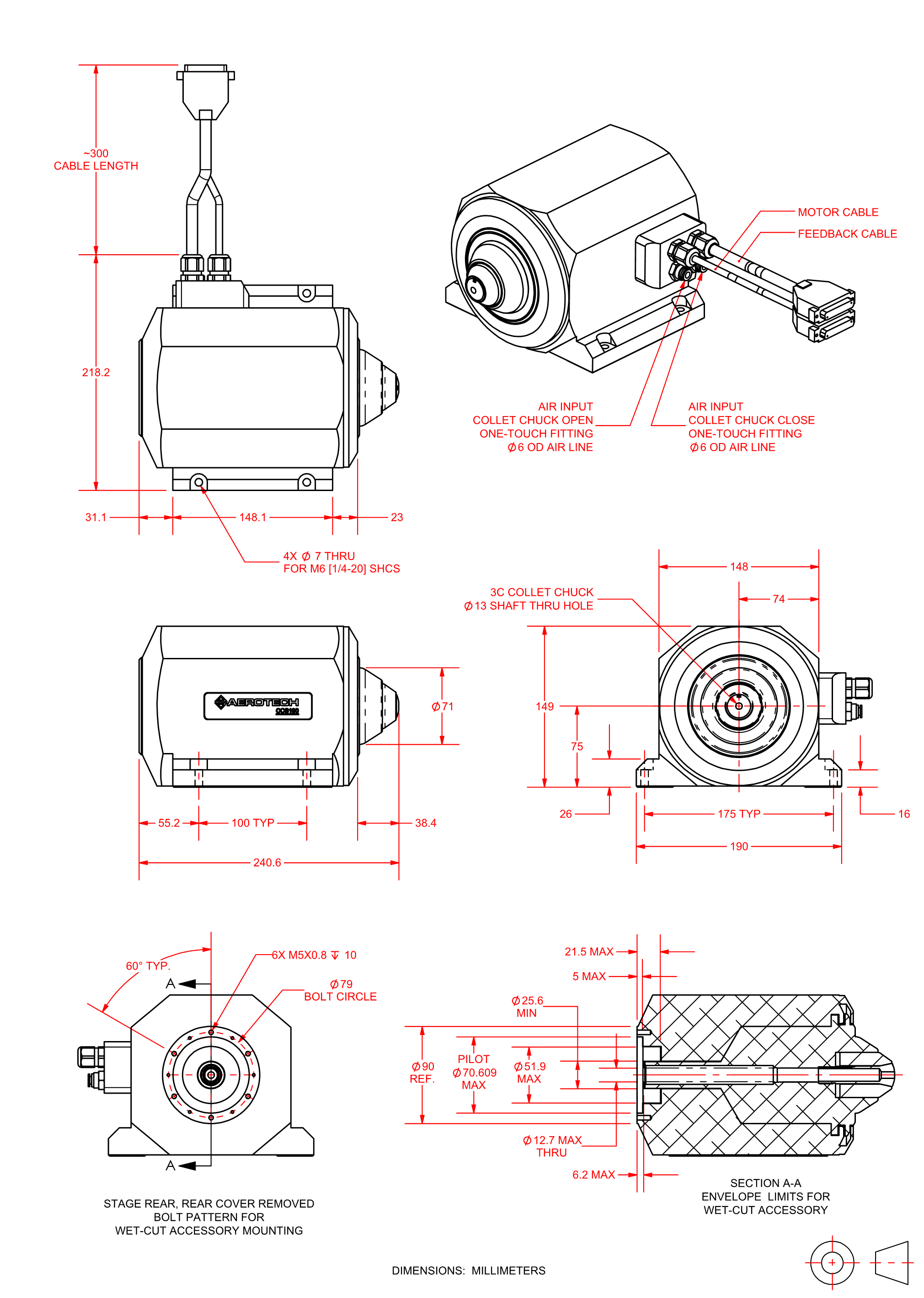

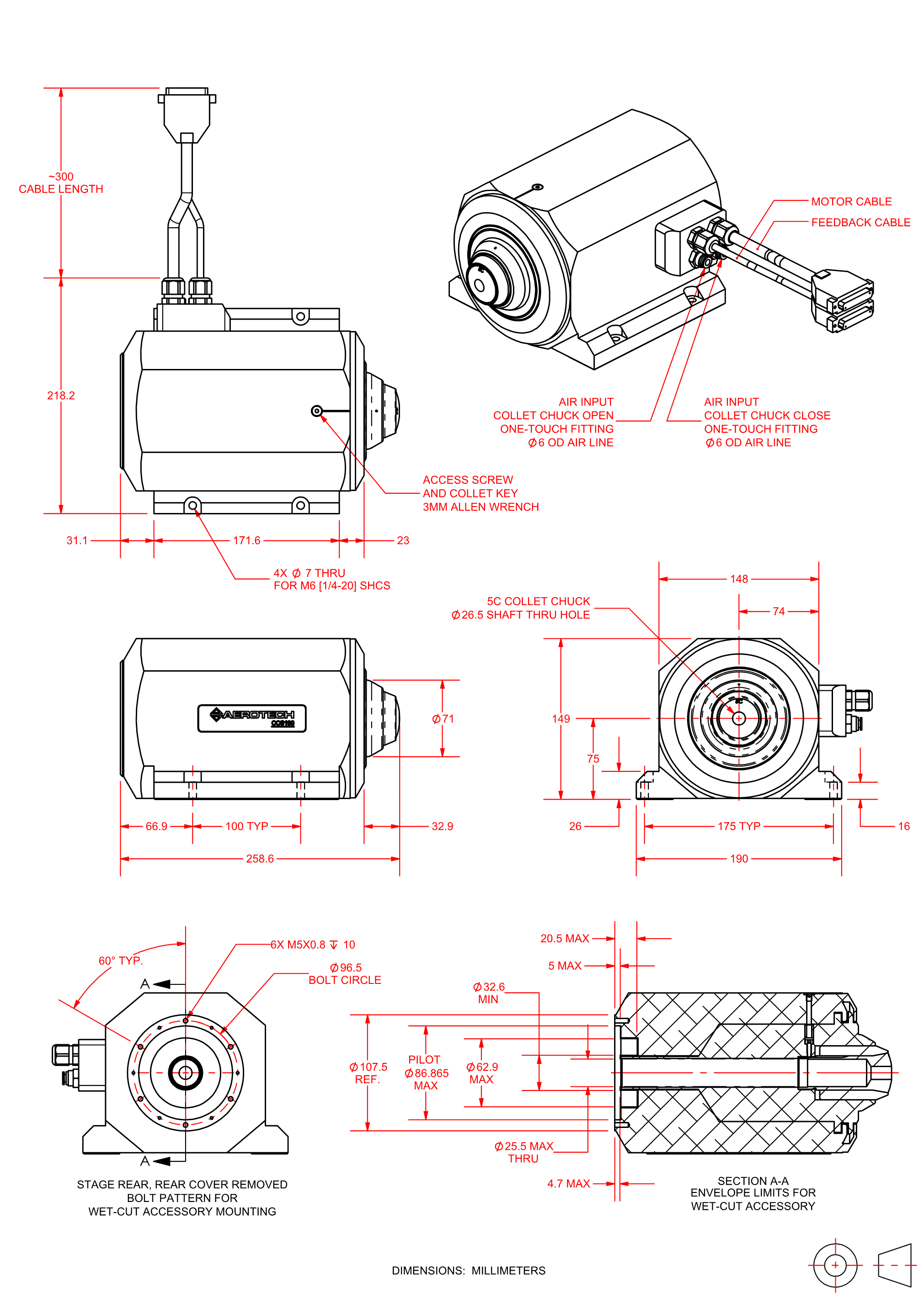

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Integral pneumatic collet chuck

- Captive collet design minimizes axial tube motion during clamp/unclamp cycles

- Clear aperture for product feed-through

- Integral mounting features support customer-supplied wet-cutting accessories

- Direct-drive brushless motor and encoder

High Precision C/D Collets

The collet chucks on the CCS family of stages accept C (for CCS190DR) or D-style/Levin (for CCS130DR) collets. These collets are readily available from machine-tool component suppliers in sizes that support tube diameters from 0.1 mm to 27 mm and provide outstanding run-out characteristics for applications requiring high-precision gripping of tubular material.

Captured Collet Design

CCS features a unique collet-chuck design that allows workpiece advance without manual realignment to compensate for axial tube motion during clamp/unclamp cycles. By moving the taper around the collet instead of drawing the collet into the taper, axial motion of the workpiece is significantly reduced, eliminating the need for part re-registration after tube advancement.

Wet-Cut Features

The CCS family is designed with mounting features on the housing to support customer supplied wet-cutting accessories. In addition, the stage is designed to tolerate moderate fluid leakage into the aperture, which is inevitable during wet-cutting operations, to prevent encoder contamination and collet-chuck failure.

Brushless Direct-Drive

To maximize positioning performance the CCS series uses direct-drive brushless motor technology. Direct-drive technology is optimized for 24/7 production environments, with no brushes to replace and no gear trains or belts to maintain. Direct-drive also provides quicker acceleration and higher top speeds than gear- or belt-driven mechanisms, yielding higher total overall throughput.

The low maintenance, high throughput characteristics of the CCS coupled with the integral material handling capability provide the lowest total cost of ownership when compared to component-level solutions.

Ordering Information

CCS130DR Mechanical-Bearing Direct-Drive Rotary Collet Stage

Stage Size (Required)

| Option | Description |

| -160 | 160 mm stage height |

Cutting Configuration (Required)

| Option | Description |

| -DCUT | Dry cutting configuration |

| -WCUT | Wet cutting configuration with fluid rotary union |

- -WCUT option requires a wet-cut seal with O-ring matched to a specific tube diameter (see Ring Seals)

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

CCS190DR Mechanical-Bearing Direct-Drive Rotary Collet Stage

Stage Size and Collet Chuck (Required)

| Option | Description |

| -240-3C | 240 mm stage height with 3C collet |

| -260-5C | 260 mm stage height with 5C collet |

Wrench (Optional)

| Option | Description |

| -WR | Wrench for changing collet |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |