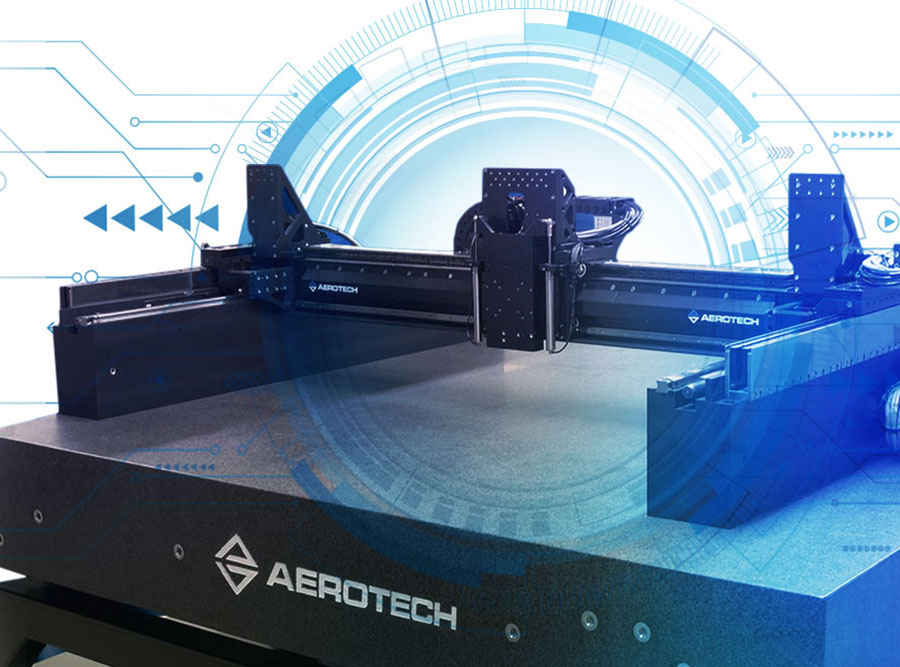

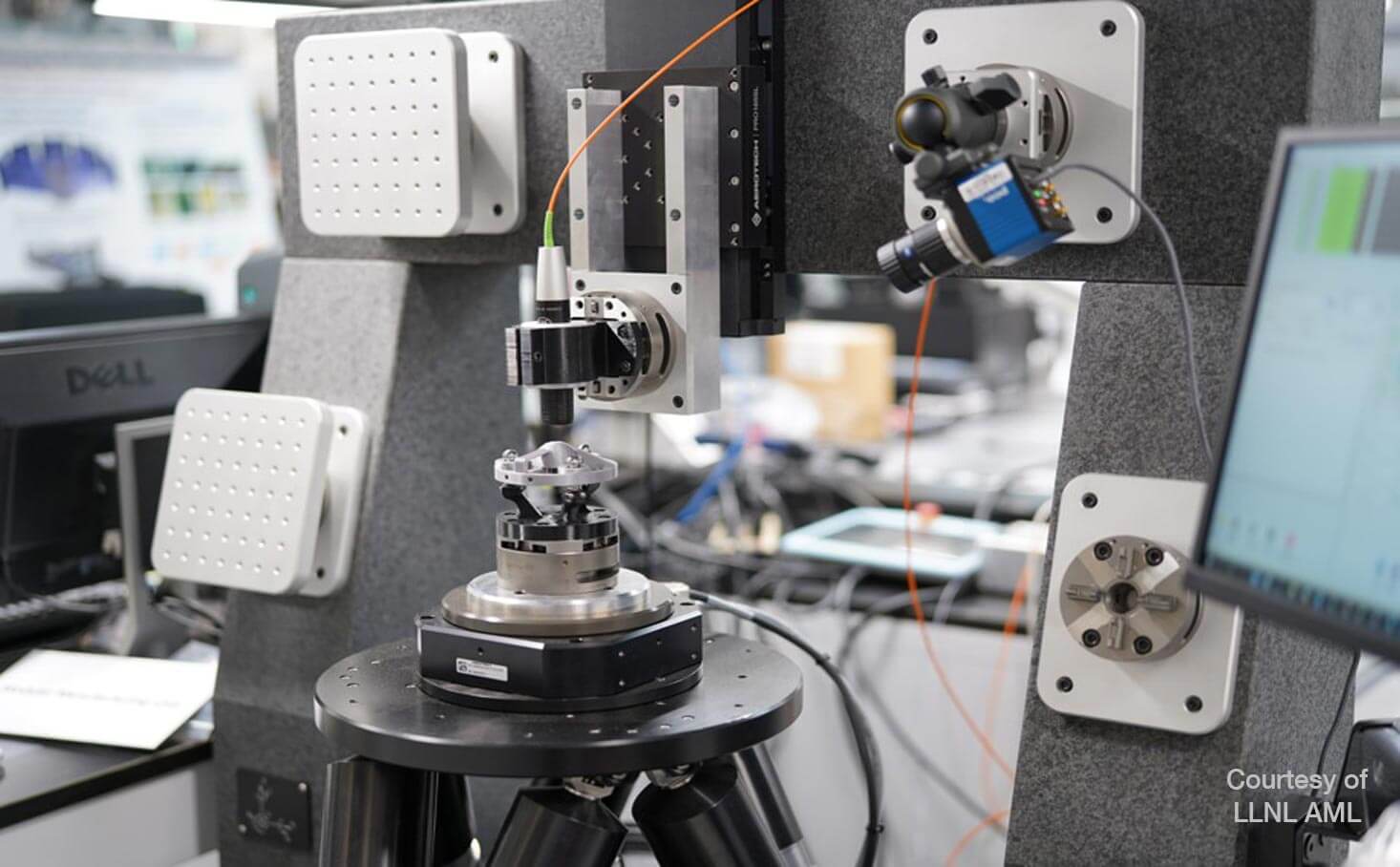

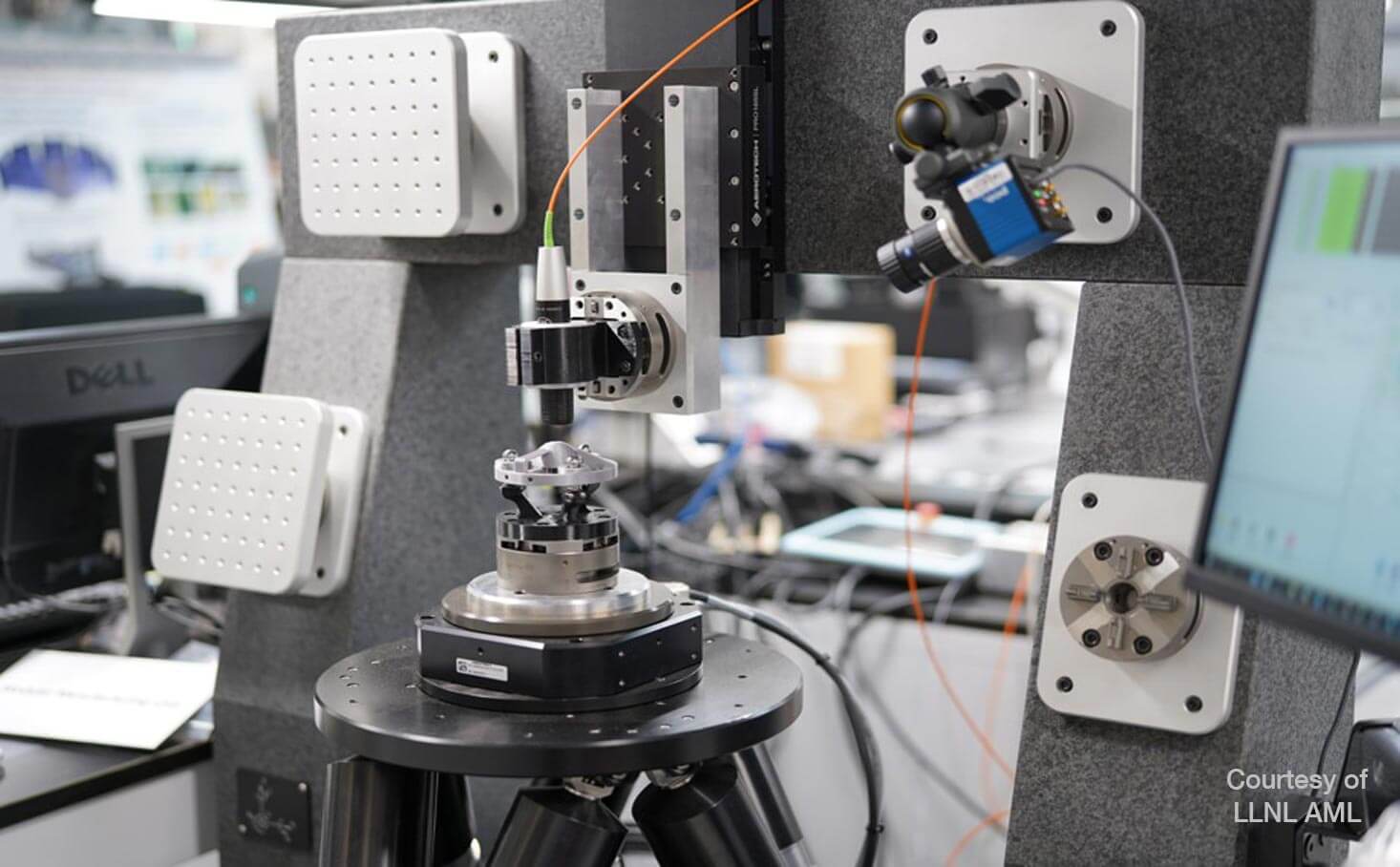

FUNDAMENTAL SCIENCE & RESEARCH

Bringing science to motion and motion to science.

You focus on the science. We focus on the motion. Together, we’ll hit your deliverables.

Precision

Our precision motion control systems bring the ultimate in accuracy and resolution to your fundamental science research, giving you a high degree of confidence in your results. With Aerotech as your partner, motion will never be a limiting factor.

Easy to Use

Motion control for research is an exact science in itself. Our software combines powerful industrial controls with an easy-to-use interface that flattens your learning curve. We also pre-configure and test your motion system, helping to get your research up and running faster.

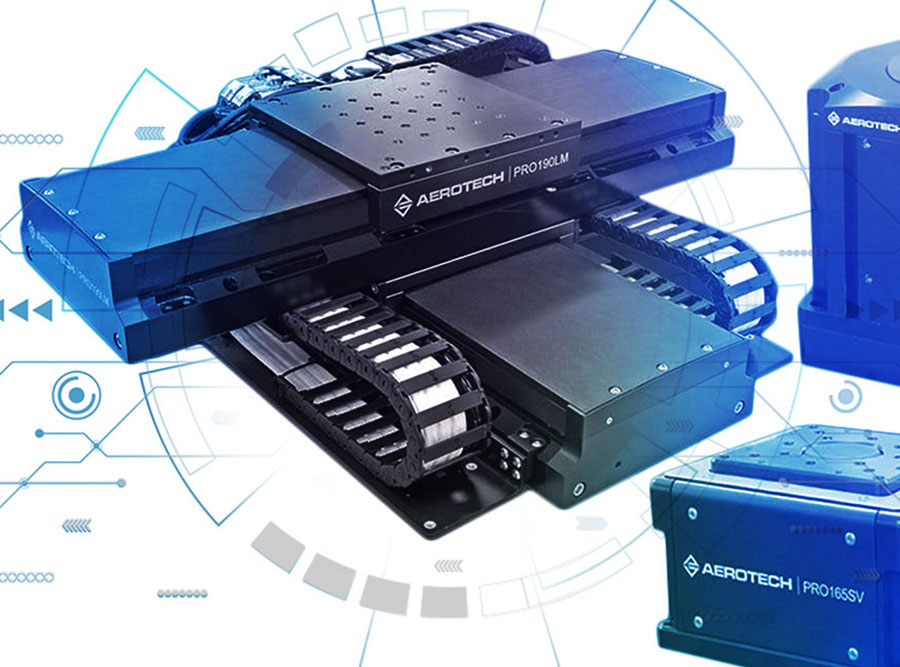

Flexible

From software to controls, our motion technology gives you the flexibility to change and adjust as your fundamental science research and motion needs evolve – all with minimal system integration. There’s no need to learn a new software interface simply to add a new motion axis to your system.

We’ll always measure up to your expectations.

-

50+ years

Serving the scientific and research markets

-

450+

Total research institutions supported by Aerotech equipment

-

40+ countries

With research institutions where Aerotech equipment is represented

Resources