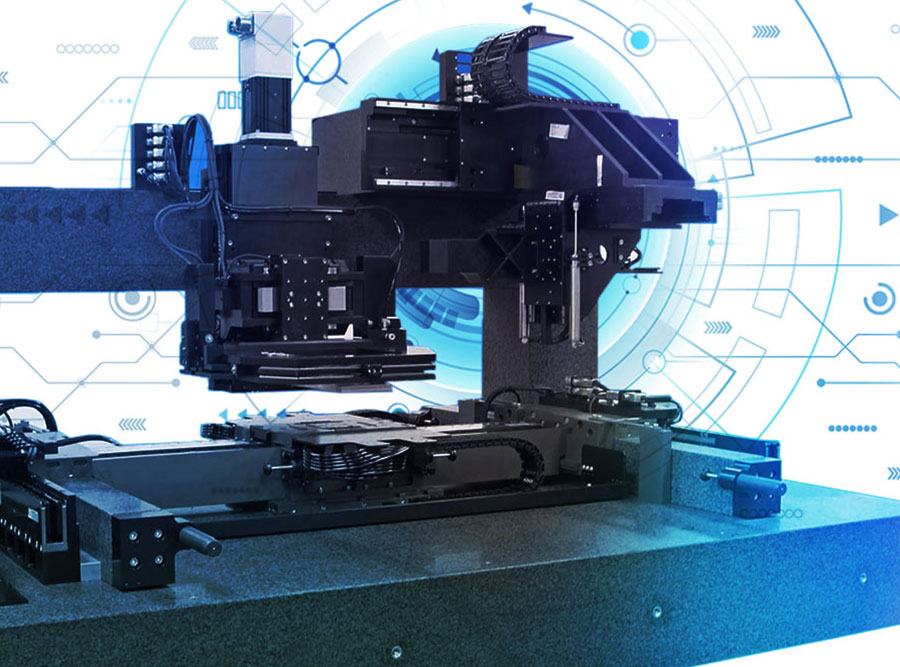

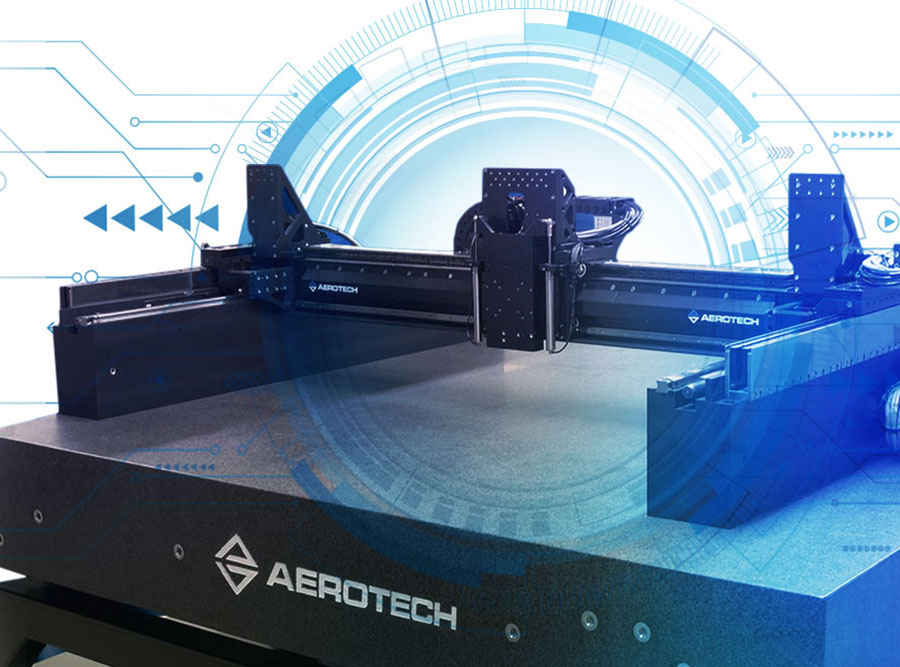

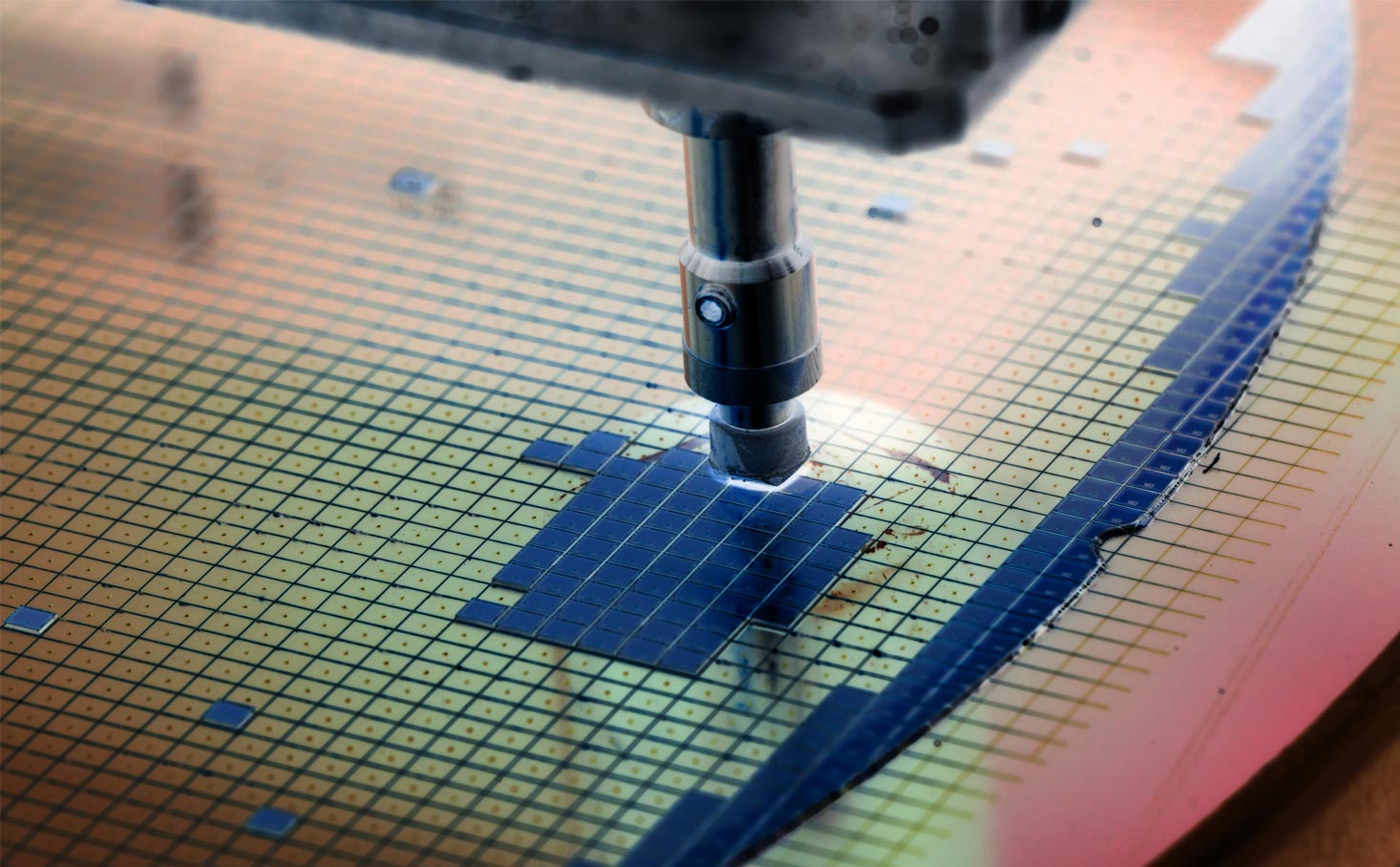

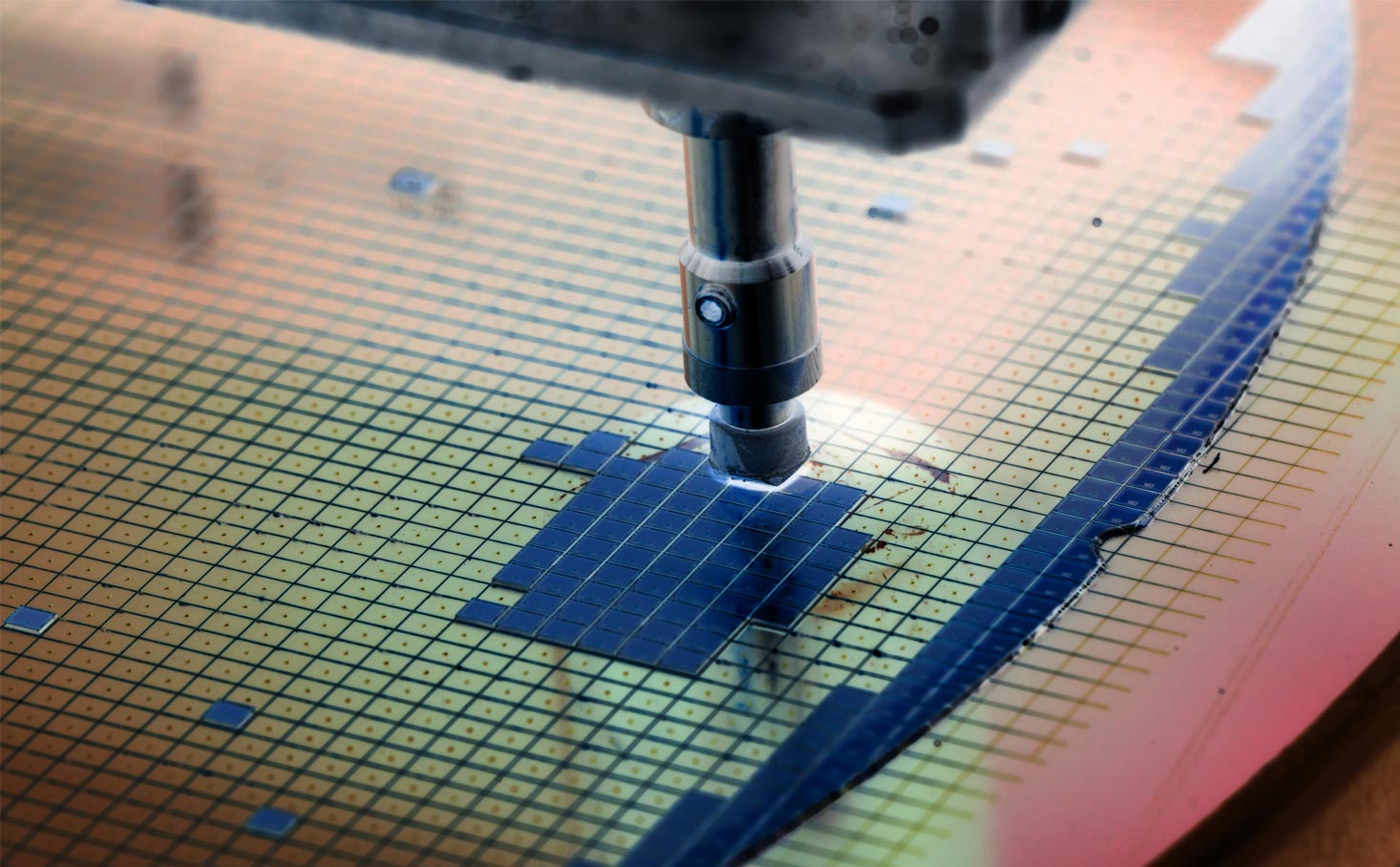

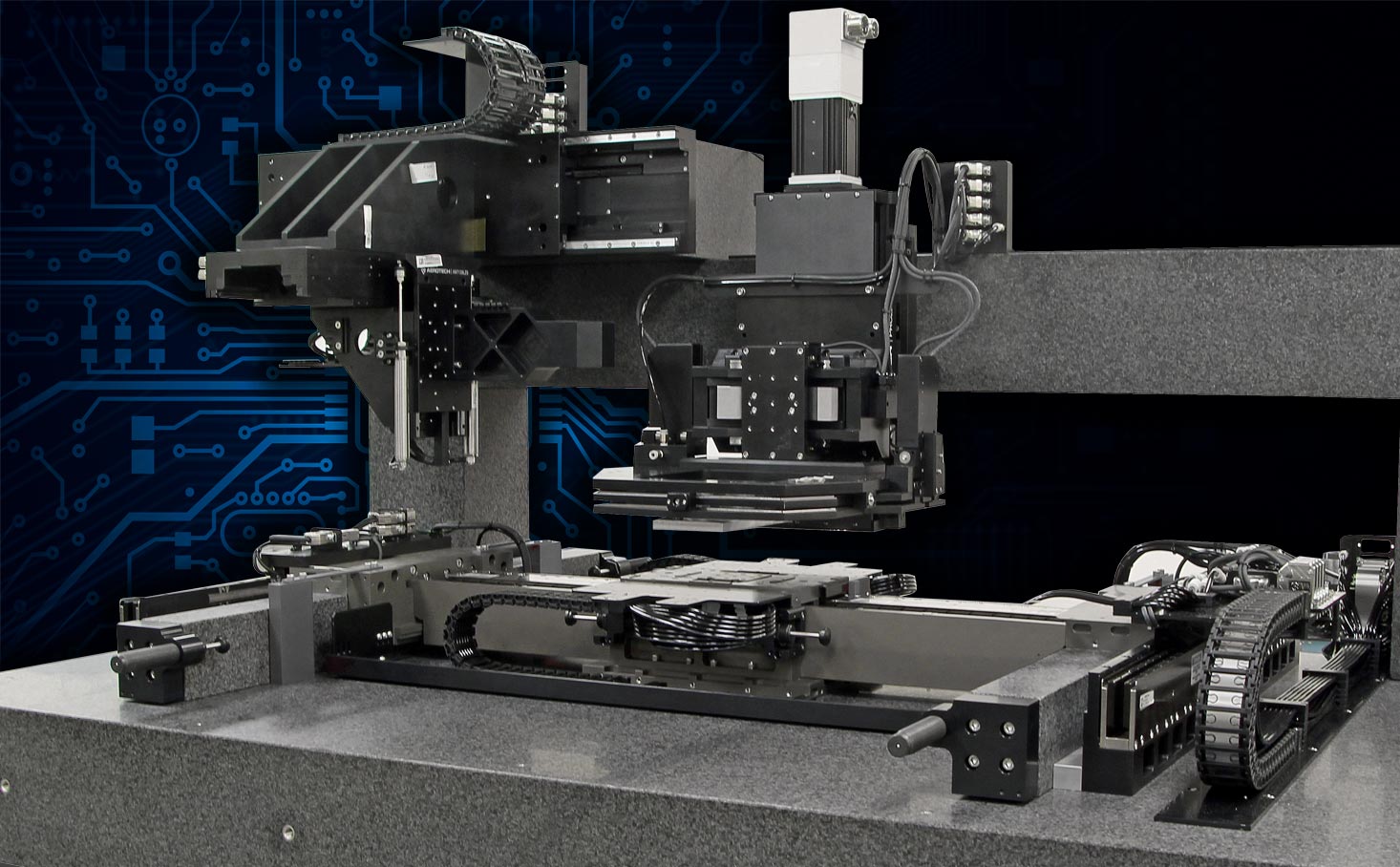

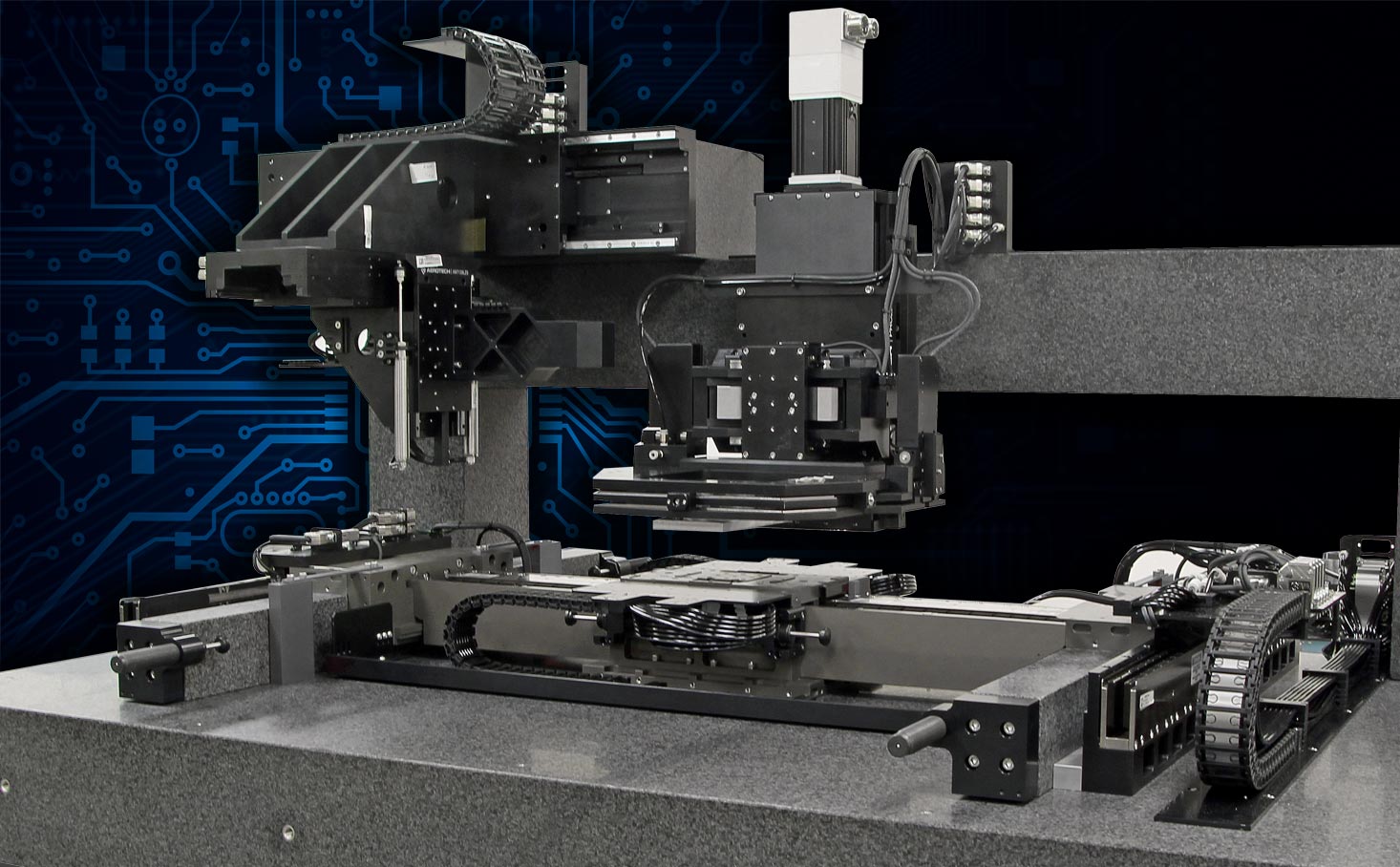

INTEGRATED CIRCUIT & WAFER PACKAGING

Improving packaging process speed and placement accuracy.

Our precision motion control and advanced mechatronics technologies enable you to attach and bond parts faster and with tighter tolerances.

Increase Machine Throughput

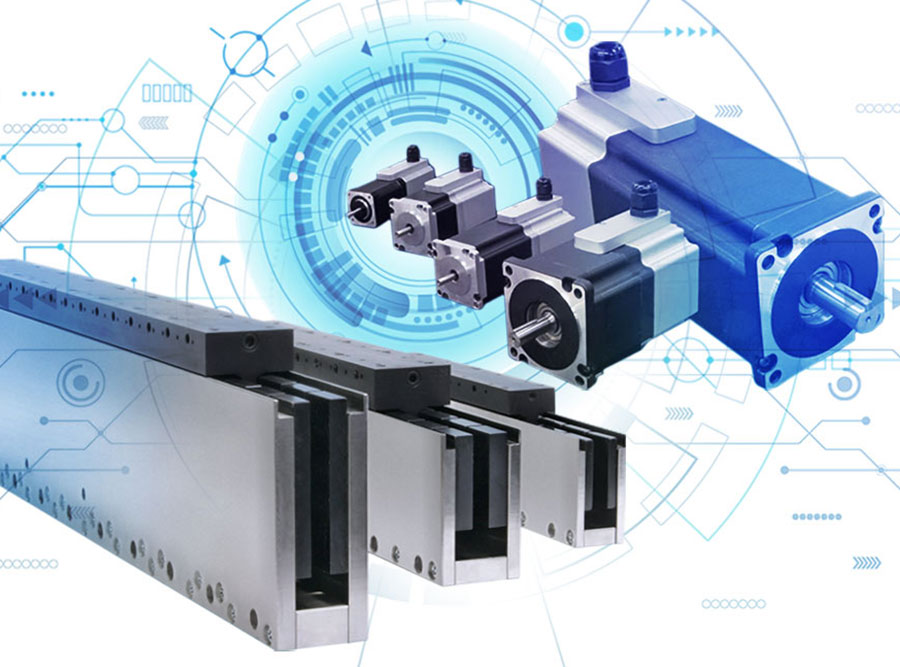

Our advanced motion control features improve system bandwidth and speed. We offer linear motors with the highest copper density for maximum force output and innovative positioning algorithms for faster step and settle.

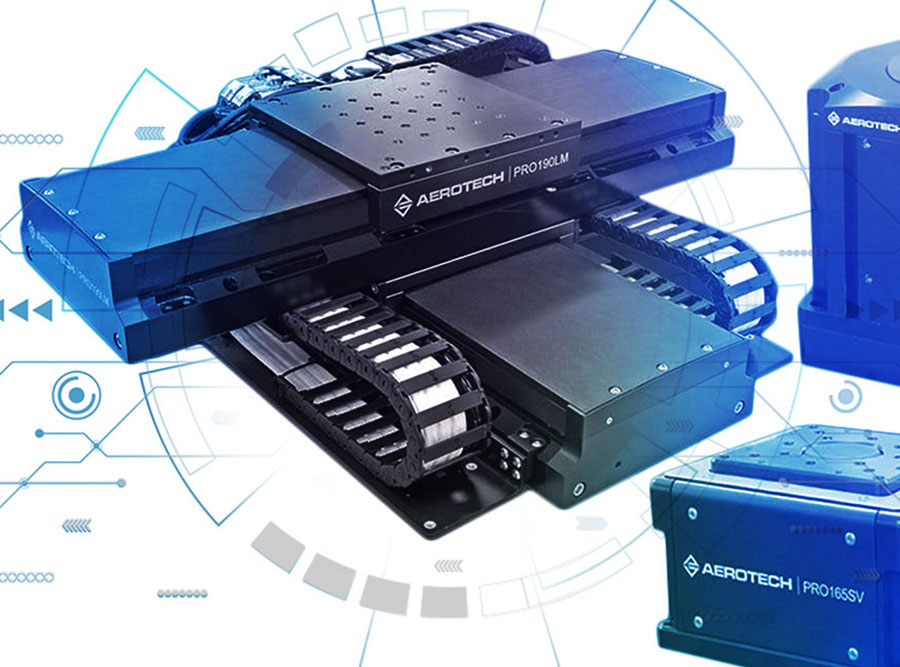

Engineered Motion

Our purpose-built motion systems combine structurally optimized mechanics with lightning fast controllers and drives to deliver the peak performance you need when nanometers and seconds count.

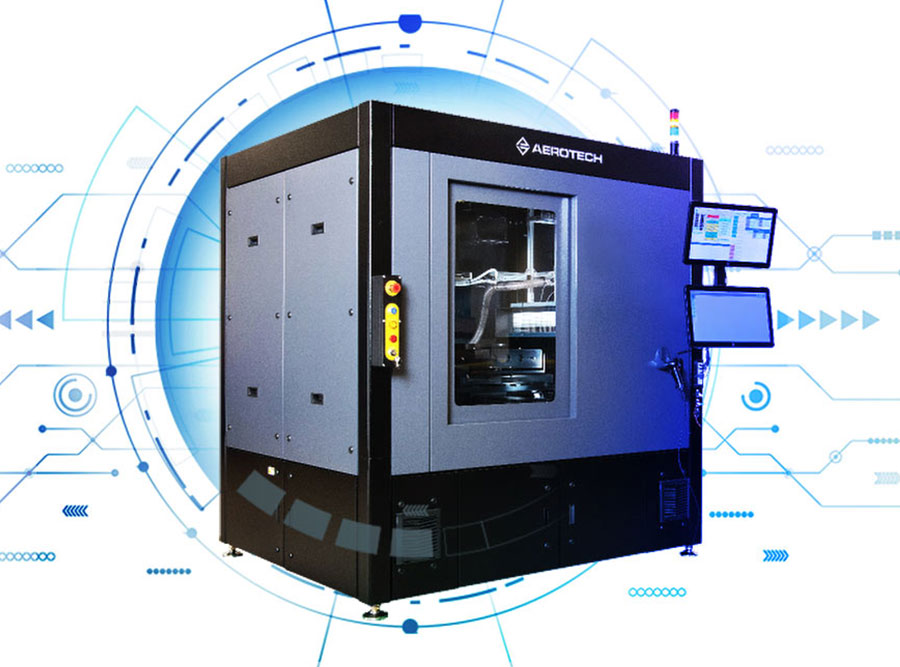

Advanced Manufacturing Capabilities

Outsource your motion system design and production so you can focus on your core technologies. We offer precision machining, assembly, electronics manufacturing and wiring, as well as cleanroom assembly and metrology capabilities.