AGV-HPO High-Accuracy Laser Scan Heads

The AGV-HPO two-axis laser scan head uses low inertia motors and mirrors with dual digital encoders for near-zero velocity and position tracking error. Its open housing design ensures low mass and a small installation footprint. Thermal drift performance is optimized via optional closed circuit water cooling for motors and the scanner housing. Optional forced-air mirror cooling increases laser power handling, allowing the AGV-HPO to maintain high precision for the most demanding laser processes. When calibrated via standard mark and measure procedures, the AGV-HPO provides valuable insight to path following error before a part is ever cut. High-reflectivity mirror coatings enable adequate power handling for both CW and pulsed laser applications.

Description

Specifications

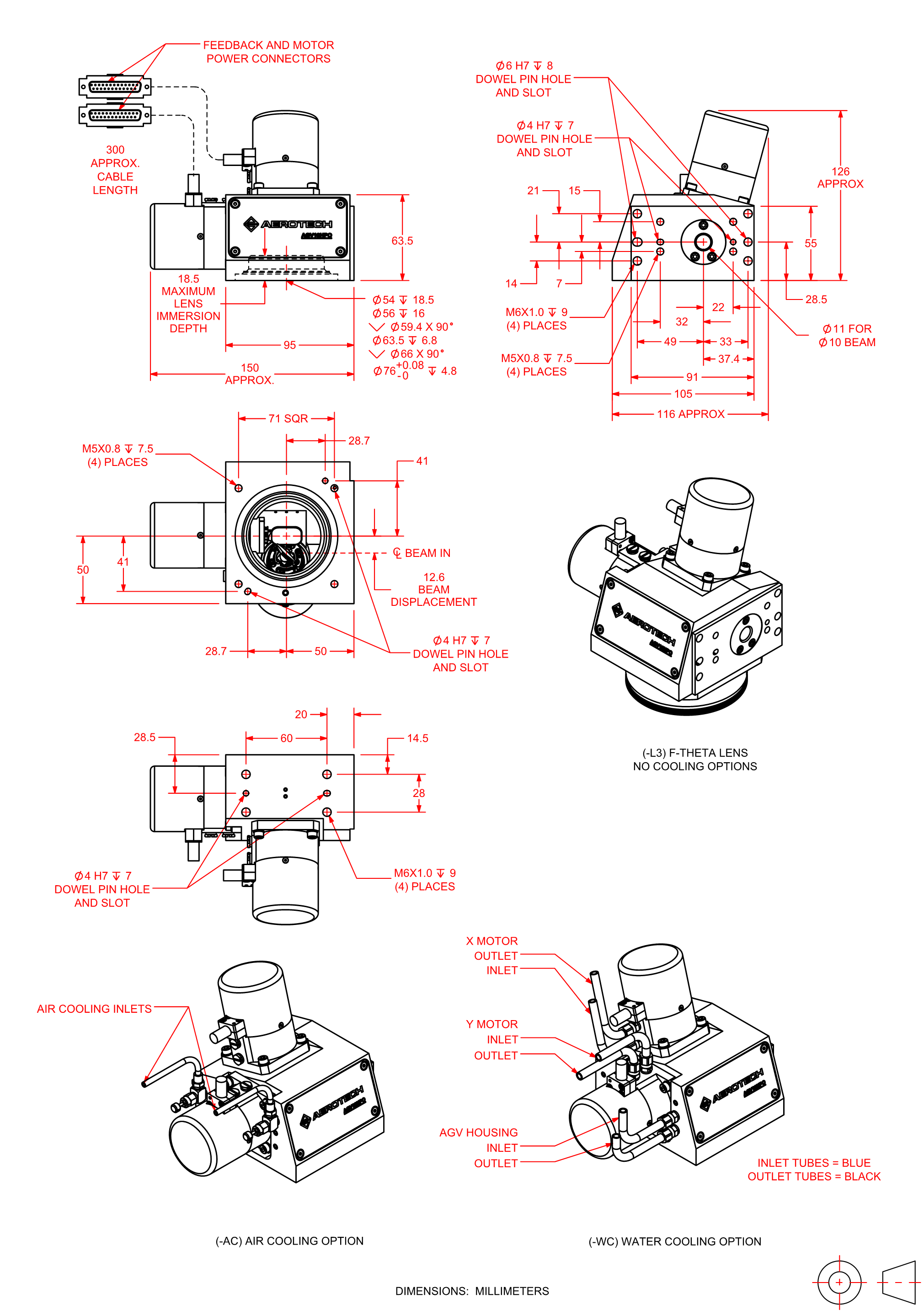

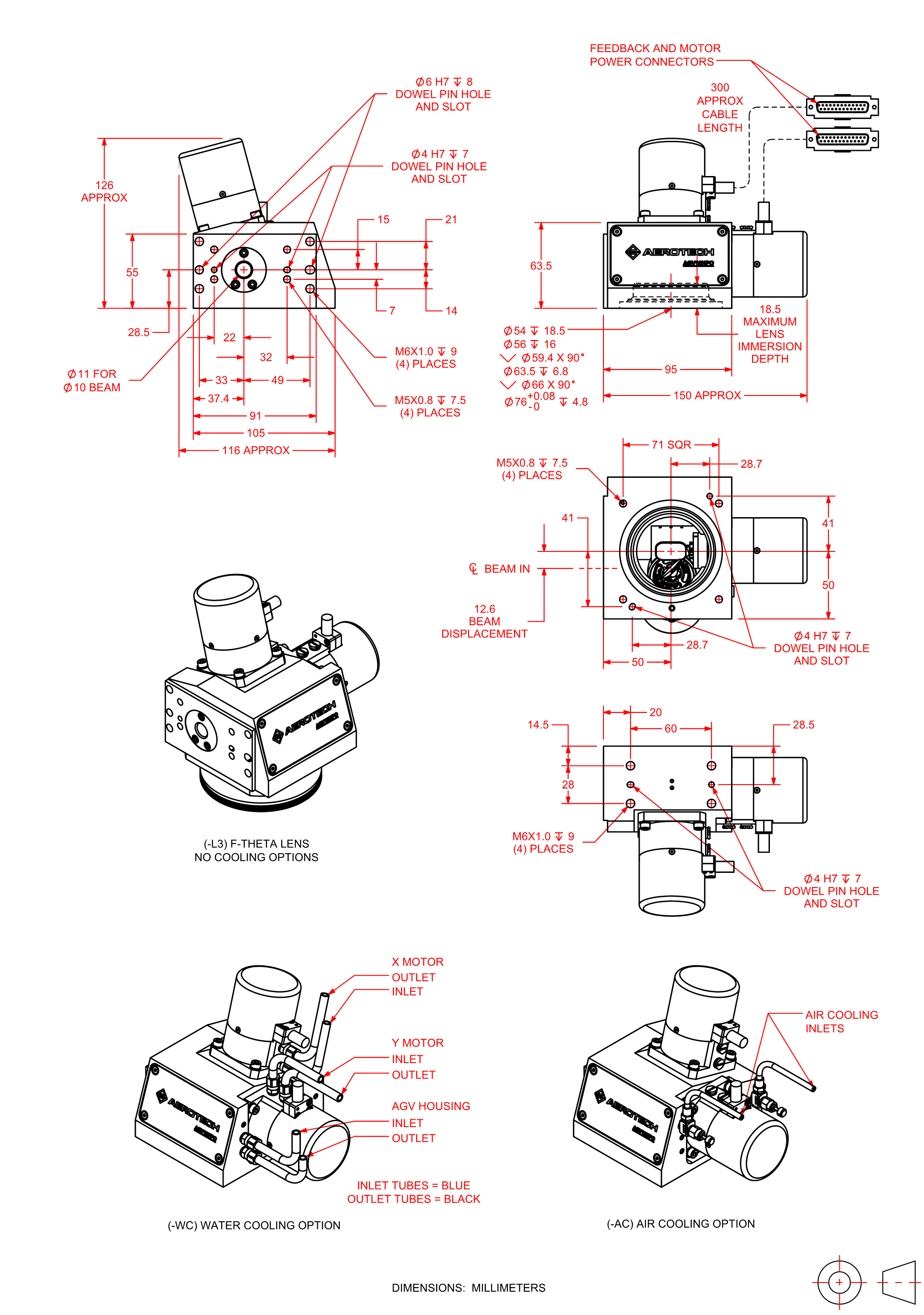

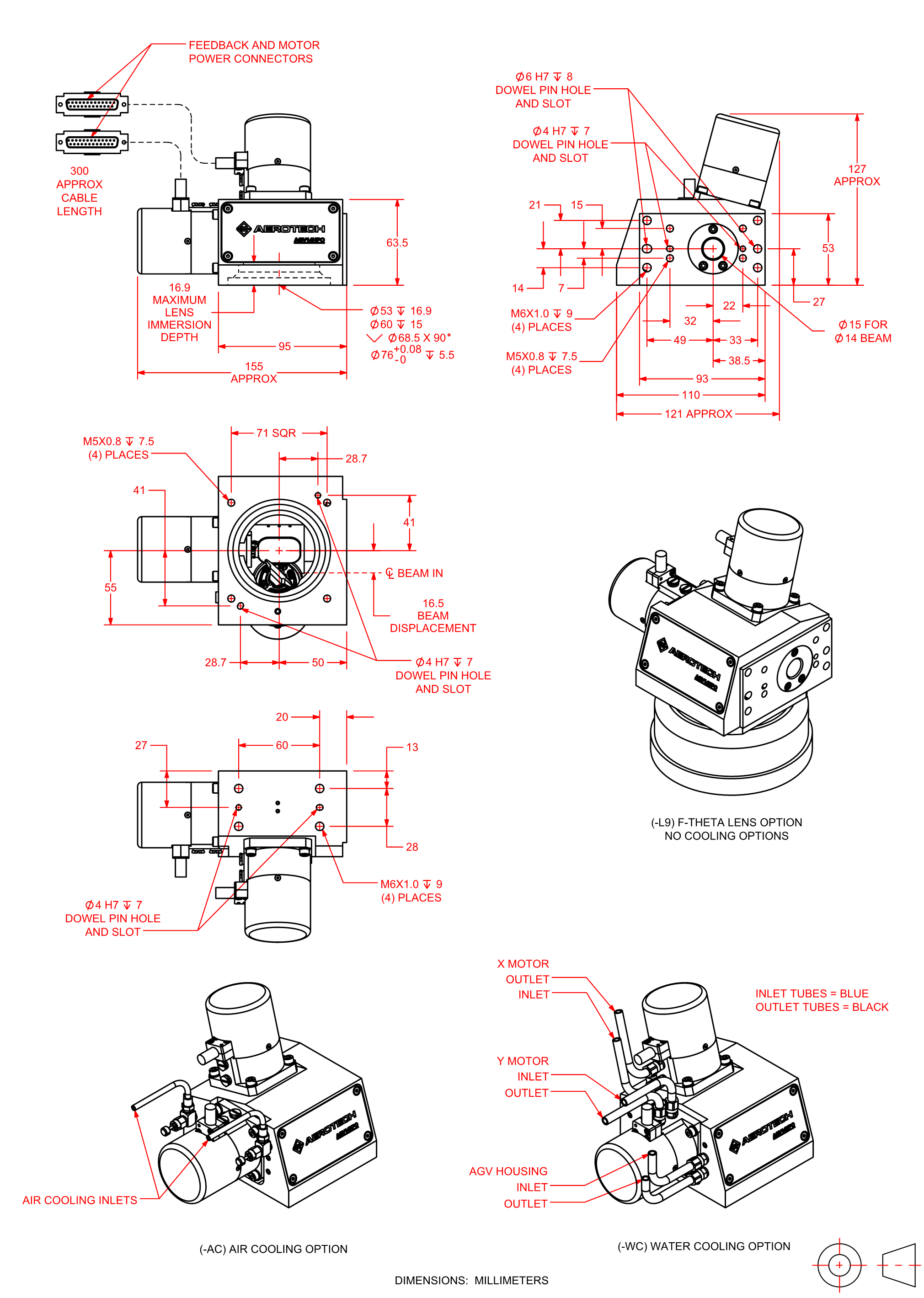

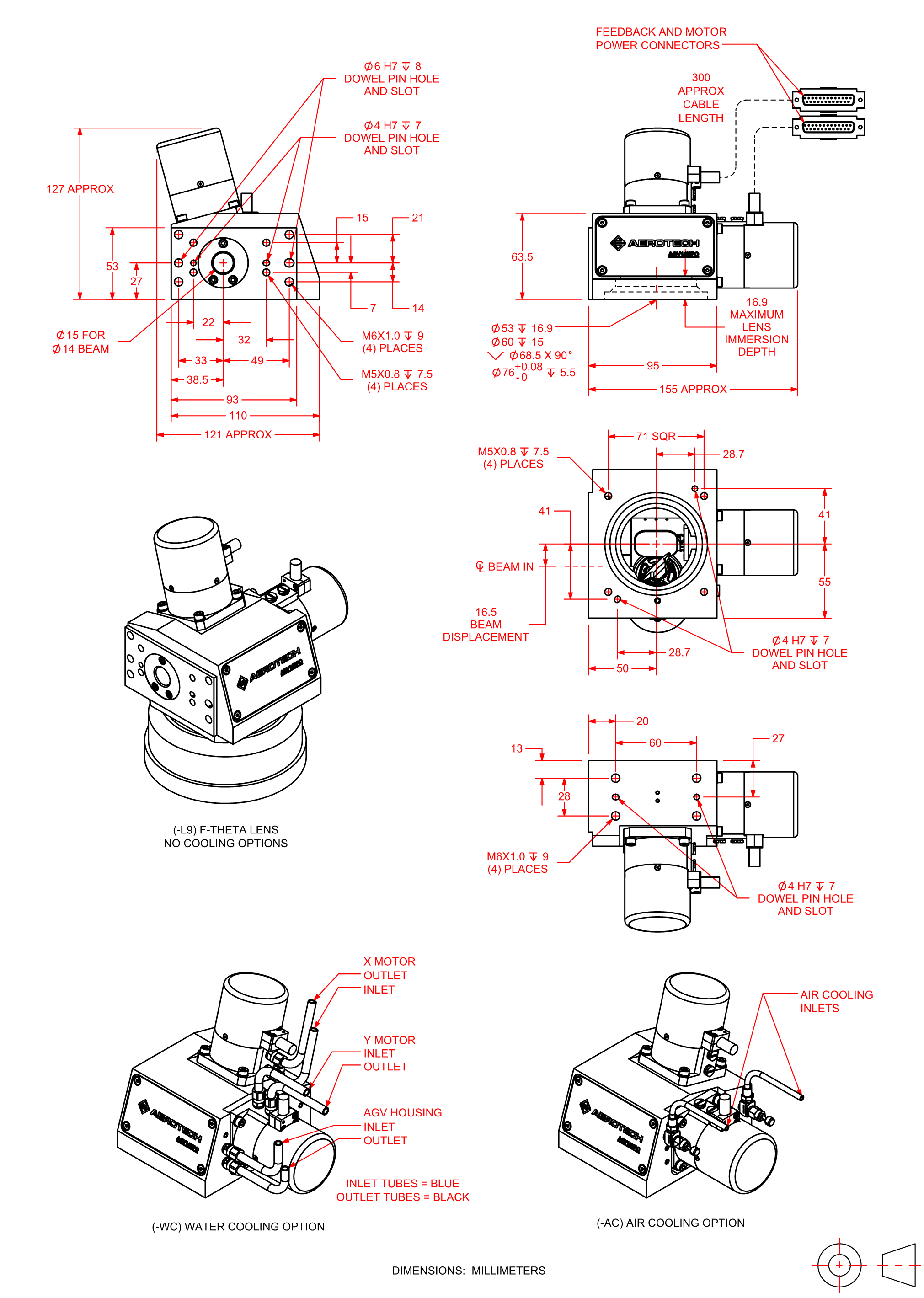

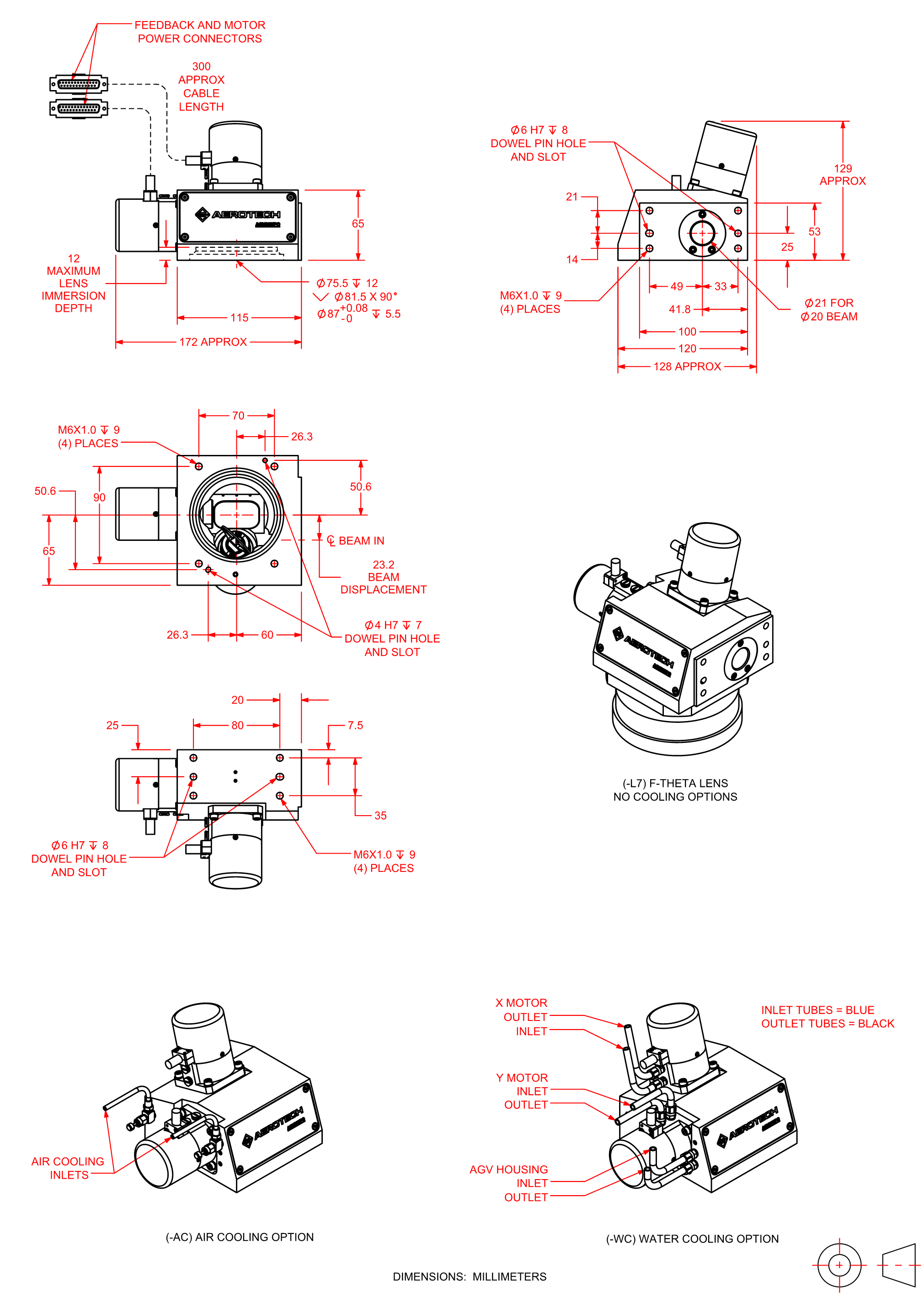

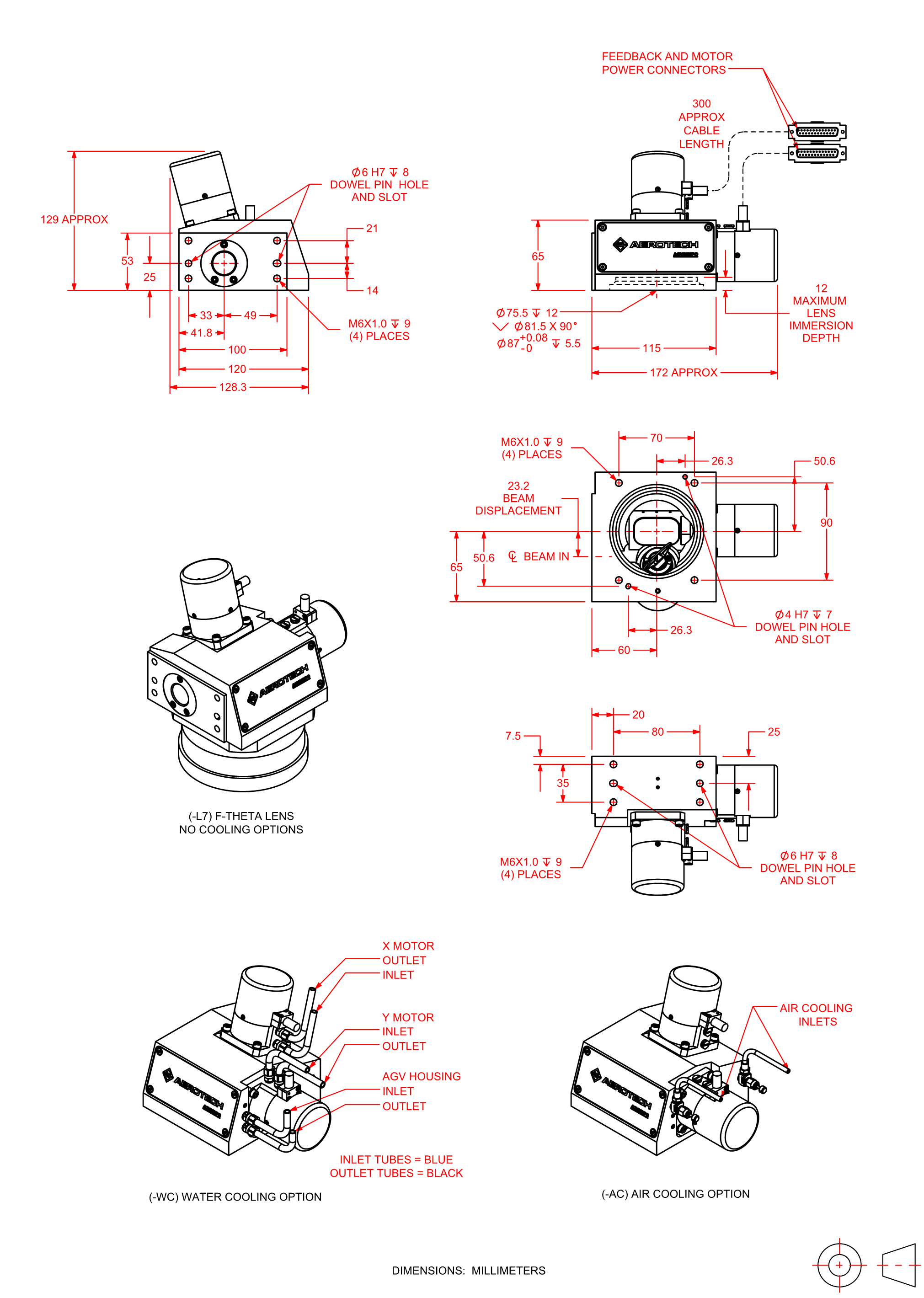

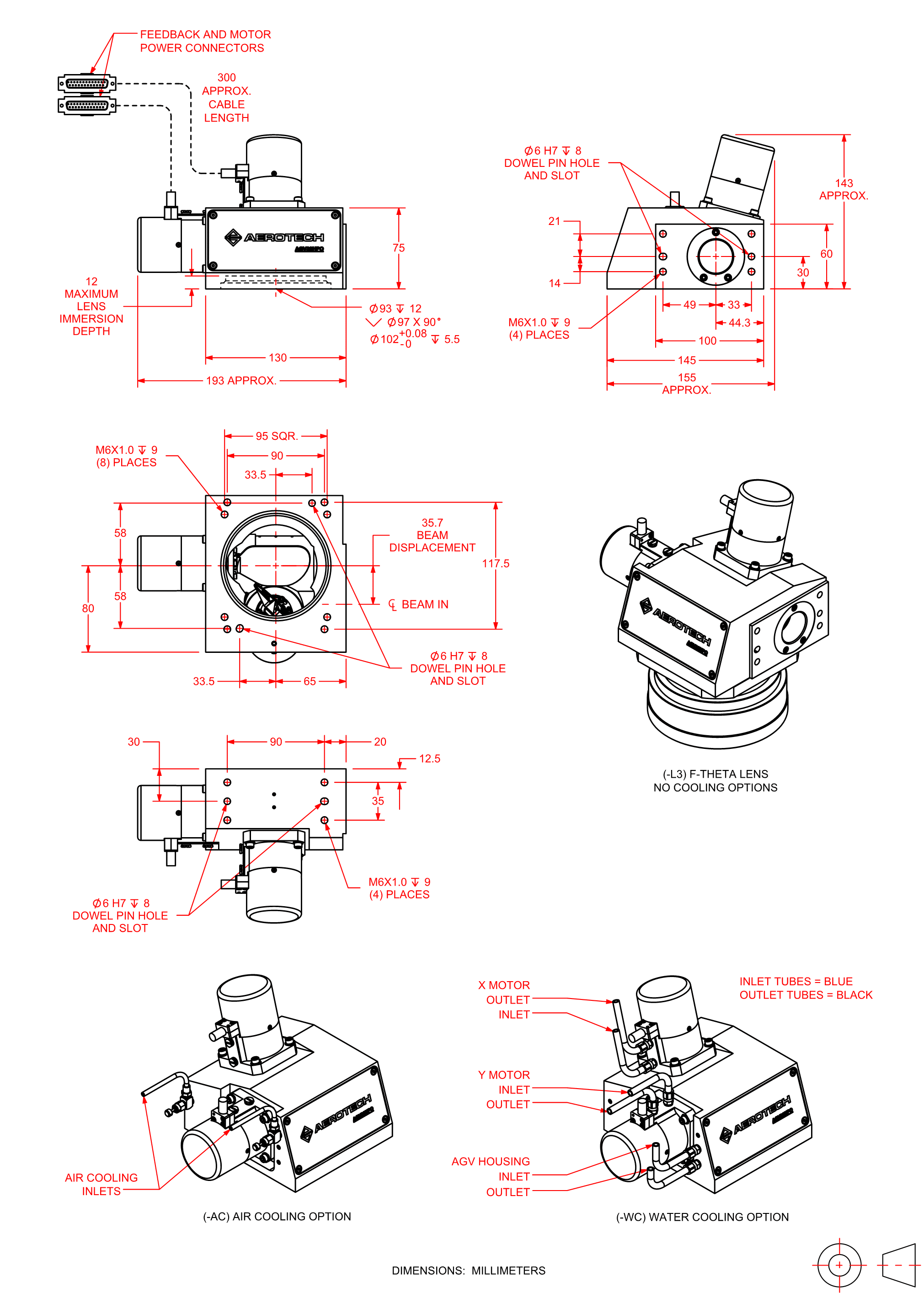

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Key Features

- Available in 10 mm, 14 mm, 20 mm & 30 mm input apertures

- Standard high-performance reflective coatings range from UV (<300 nm) to CO2 (>10,600 nm)

- Digital position resolution of >24 bits

- Thermally stable open-housing design with optional closed circuit water motor cooling & gas mirror cooling

- Dual digital encoder feedback eliminates velocity error & enables single-digit, micron-level accuracy throughout scanner Field of View (FOV)

Key Applications

The AGV-HPO is ideal for all types of 2D laser scanning applications where precision and throughput are critical to quality, including:

- Glass cutting

- Via drilling

- Surface texturing

- Micromachining

Design Choices

The AGV-HPO is available with 10, 14, 20 and 30 mm input apertures with right- or left-side beam entry. It can be equipped with an F-Theta or telecentric lens directly from Aerotech. Alternatively, users can acquire the focusing optic directly from an outside supplier and pair it with an Aerotech-supplied spacer ring (to ensure back reflections through the optic do not damage scanner mirrors). Mirror coatings for a wide range of UV, visible, IR and CO2 wavelengths are supported. Coatings optimized for ultra-fast lasers are also available.

Powerful Controls Enable Real-Time Process Visibility

Powered by our Automation1 PC-based motion controller and driven by linear amplifiers, the AGV-HPO can execute motion at trajectory rates up to 200 kHz. The location of the AGV-HPO’s mirrors can be captured and analyzed in real time. With direct access to the scanner positions, you won’t need to program delay parameters to compensate for lag and tracking errors in the servo system. The process can be optimized prior to marking the part, saving time and reducing material waste. You can also control the laser’s state based on in-position and velocity criteria, further reducing programming complexity.

Advanced Programming Features

The AGV-HPO uses all the advanced motion and position synchronized output (PSO) capabilities developed for our traditional servo-based laser processing applications. Contouring functions like acceleration limiting automatically reduce speeds in tight corners or small radii to minimize overshoot. With PSO, the laser can be triggered based on the mirror’s position feedback, ensuring consistent spot overlap as the scanner changes speed. Infinite Field of View (IFOV) seamlessly combines servo and scanner motion to extend the scanner’s marking capability across the entire travel of the servo stages, eliminating stitching errors that can occur in a more traditional move-expose-repeat process.

Ordering Information

AGV-HPO Series High-Accuracy Laser Scan Head

| Option | Description |

| AGV10HPO | 2-axis galvanometer scanner with 10 mm diameter beam aperture and integral high-precision feedback |

| AGV14HPO | 2-axis galvanometer scanner with 14 mm diameter beam aperture and integral high-precision feedback |

| AGV20HPO | 2-axis galvanometer scanner with 20 mm diameter beam aperture and integral high-precision feedback |

| AGV30HPO | 2-axis galvanometer scanner with 30 mm diameter beam aperture and integral high-precision feedback |

Beam Entry (Required)

| Option | Description |

| -BE1 | Right-side laser beam entry (standard) |

| -BE2 | Left-side laser beam entry |

Wavelength of Mirror Coating (Required)

| Option | Description |

| -W001 | 10.6 µm |

| -W002 | Durable-Silver (450 nm - 10.6 µm) |

| -W003 | 1552 nm |

| -W004 | 1064 nm |

| -W005 | 1030 nm |

| -W006 | 532 nm |

| -W007 | 515 nm |

| -W008 | 355 nm |

| -W009 | 343 nm |

| -W012 | 9.3 µm |

| -W011S* | 1030/515/343 nm Tri-band |

- Custom coatings available. Contact factory for details.

- * Dynamic performance specifications do not apply to this option. Contact the factory for more information.

F-Theta Lenses Available (Optional)(1, 2)

| Option | Description |

| -Lxx | See Table 1: F-Theta Lenses Available |

Mounting Plate (Optional)

| Option | Description |

| -MP | Mounting plate |

- -MP option is only available with closed scanner housing (AGVxxHP) models.

Air Cooling (Optional)

| Option | Description |

| -AC | Air cooling |

Water Cooling (Optional)

| Option | Description |

| -WC | Water cooling |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

Lens Mounting Adapters (to be ordered as separate line item)

| Option | Description |

| LM10HP-XXX | Lens mount adapter for AGV10HP(O); standard versions support the lens configurations offered by Aerotech; custom versions available on request |

| LM14HP-XXX | Lens mount adapter for AGV14HP(O); standard versions support the lens configurations offered by Aerotech; custom versions available on request |

| LM20HP-XXX | Lens mount adapter for AGV20HP(O); standard versions support the lens configurations offered by Aerotech; custom versions available on request |

| LM30HP-XXX | Lens mount adapter for AGV30HP(O); standard versions support the lens configurations offered by Aerotech; custom versions available on request |

Table 1: F-Theta Lenses Available (Optional)(1, 2)

| AGV10HPO | AGV14HPO | AGV20HPO | AGV30HPO | |

| -L1 | 1552-100-T 55 mm sq. FOV |

- | 10600-100-T 35 mm sq. FOV |

35 mm sq. FOV 10600-255 100 mm sq. FOV |

| -L2 | 1552-163-T 90 mm sq. FOV |

- | 10600-160 75 mm sq. FOV |

1064-200 65 mm sq. FOV_4 |

| -L3 | 1064-100 65 mm sq. FOV(4) |

1552-100-T 45 mm sq. FOV |

10600-255 160 mm sq. FOV |

1064-255 150 mm sq. FOV(4) |

| -L4 | 1064-255 150 mm sq. FOV(4) |

1552-163-T 90 mm sq. FOV |

1064-100-T 40 mm sq. FOV |

1064-500 230 mm sq. FOV(4) |

| -L5 | 1064-160 105 mm sq. FOV(4) |

1064-100 35 mm sq. FOV(4) |

1064-163 70 mm sq. FOV(4) |

- |

| -L6 | 1064-163-T 90 mm sq. FOV |

1064-100-T 60 mm sq. FOV(4) |

1064-163-T 70 mm sq. FOV |

- |

| -L7 | 1030-100-T 40 mm sq. FOV |

1064-160 80 mm sq. FOV(4) |

1064-255 150 mm sq. FOV(4) |

- |

| -L8 | 1030-163-T 90 mm sq. FOV |

1064-163-T 85 mm sq. FOV |

532-255 145 mm sq. FOV(4) |

- |

| -L9 | 532-100 55 mm sq. FOV(4) |

1064-170 110 mm sq. FOV(4) |

- | - |

| -L10 | 532-100-T 60 mm sq. FOV(4) |

1030-100-T 30 mm sq. FOV |

- | - |

| -L11 | 532-160 105 mm sq. FOV(4) |

1030-163-T 90 mm sq. FOV |

- | - |

| -L12 | 532-163-T 75 mm sq. FOV |

532-100-T 60 mm sq. FOV(4) |

- | - |

| -L13 | 515-100-T 30 mm sq. FOV |

532-160 105 mm sq. FOV(4) |

- | - |

| -L14 | 515-163-T 40 mm sq. FOV |

532-163-T 75 mm sq. FOV |

- | - |

| -L15 | 355-53-T 15 mm sq. FOV |

532-170 100 mm sq. FOV(4) |

- | - |

| -L16 | 355-100-T 50 mm sq. FOV |

515-100-T 30 mm sq. FOV |

- | - |

| -L17 | 355-160 90 mm sq. FOV |

515-163-T 40 mm sq. FOV |

- | - |

| -L18 | 355-163-T 80 mm sq. FOV |

355-53-T 5 mm sq. FOV |

- | - |

| -L19 | 355-255 140 mm sq. FOV |

355-163-T 80 mm sq. FOV |

- | - |

| -L20 | - | 355-255 140 mm sq. FOV |

- | - |

| -L21 | - | 343-53-T 5 mm sq. FOV |

- | - |

| -L22 | - | 343-163-T 70 mm sq. FOV |

- | - |

| -L23 | - | 343-255 115 mm sq. FOV |

- | - |

- Lenses specified as XXX-YYY(-T), where “XXX” represents the wavelength in nanometers, “YYY” represents the focal length in millimeters, and the presence of “-T” indicates a telecentric design.

- Input beam diameter is assumed to be equal to scan head entrance aperture at 1/e^2 Gaussian profile.

- Reported field-of-view (FOV) sizes are approximate and may be subject to minor variation as a function of the application’s laser and optical paramterers. Contact factory for details.

- Certain F-theta lenses are not recommended for use with short-pulse lasers (picosecond and femtosecond pulse durations). Contact factory for alternate lens options that are compatible with short-pulse lasers.

- Custom lenses available. Contact factory for details.