Capability Overview

Capability Overview

Enhanced Scanner Control (ESC) – Advanced Control Algorithm for Laser Scan Head Motion

Bryan Germann

Product Manager

Enhanced Scanner Control (ESC) is an advanced control algorithm that improves laser scan head motion in many ways, including:

- Reducing tracking error for all laser scan head motion in applications requiring high-dynamic performance

- Enabling faster acceleration without hitting drive/motor voltage bus limits

- Eliminating resonance-based errors

- Dramatically reducing or eliminating settle times for step and settle motion

- Enabling higher process speeds without exceeding tracking error limits

Overcoming Traditional Servo Control Loop Limitations

To achieve high-quality outcomes in high-precision laser processing applications, precision and speed are critical. Traditional laser scan heads often struggle with the trade-off between speed and accuracy, especially in applications requiring intricate motion patterns that demand high-frequency and high-acceleration motion. ESC addresses these challenges by using novel software algorithms to increase the dynamic limits of a given scanner hardware configuration. User benefits include reduced cycle times, enhanced throughput and superior product quality, making ESC an essential feature for industries demanding the utmost in laser processing performance.

Benefits for Step & Settle Motion

ESC dramatically improves step and settle performance for laser scan heads, a crucial motion profile used in common laser processing applications. One such application is called percussive drilling, which involves moving between thousands of locations and triggering a laser to drill a vertical hole at the location only after the motion error has settled to a specified target, or settle window. Electronics manufacturing applications like printed circuit board (PCB) drilling use the percussive drilling process to form the via holes that allow circuits from different layers to be connected as depicted in Figure 1.

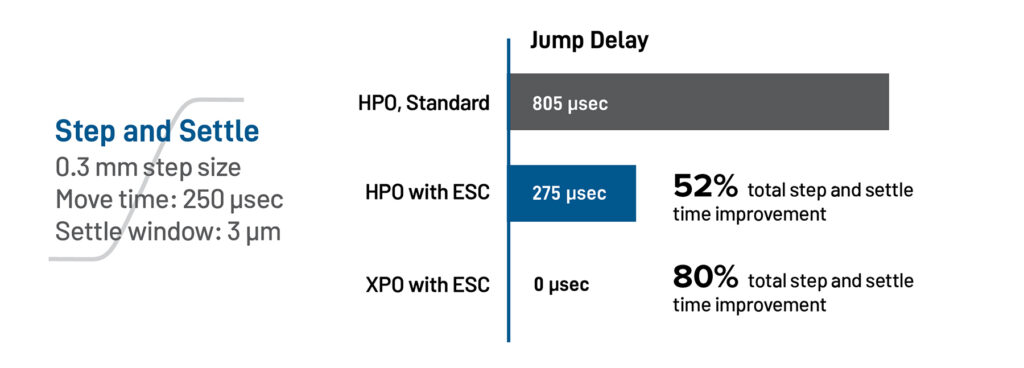

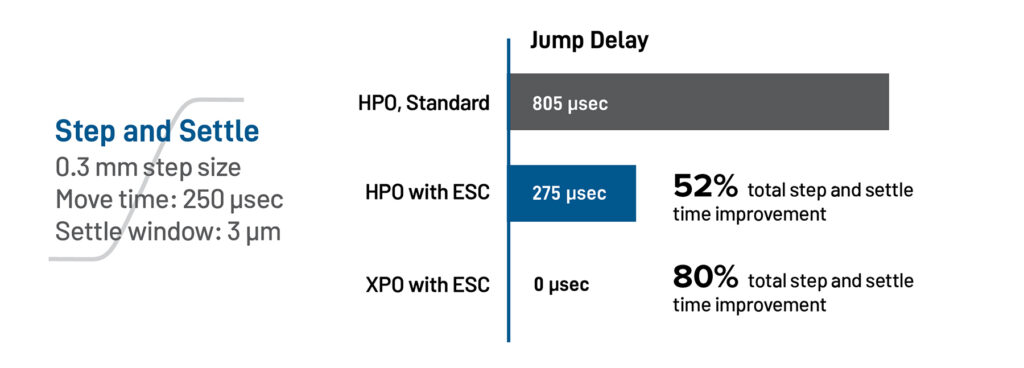

The step and settle motion profile uses peak acceleration and deceleration between two points, waiting some amount of time (referred to as jump delay) to allow the motion error to settle, then firing the laser a number of times to drill to the specified target depth before finally moving to the next location. No work can be performed during the jump delay, wasting valuable time. It is common for a profile to have thousands or tens of thousands of these moves with varying distances but a common settle window. The total part cycle time for a PCB drilling operation is directly related to the time it takes to make a move, settle the position error and fire the laser for all points. Any decrease in these times improves overall process productivity.

To demonstrate this, Aerotech’s AGV-HPO (with and without ESC enabled) and AGV-XPO (with ESC enabled) completed a 0.3 mm step in 250 microseconds with a 1% position error threshold before firing the laser, translating to a 0.003 mm settle window. Figure 2 depicts the improvement enabled by ESC for both scan heads.

In this test, using ESC led to a 52% improvement for the AGV-HPO and a 80% improvement for the AGV-XPO. Eliminating hundreds of microseconds across thousands of holes can yield significant productivity improvements for any system using these scanners for this process.

Applications that will benefit from enhanced step and settle performance include:

- Printed circuit board (PCB) drilling (electronics manufacturing)

- Laser-induced forward transfer (electronics manufacturing)

- Through glass via (TGV) processing (semiconductor manufacturing)

Benefits for High Frequency Circular Contouring Motion

High-frequency circular contouring motion is another common motion profile. Maintaining the motion’s circularity without distortion and within the target application’s peak error limit is vital. ESC enhances high-frequency circular contouring motion for laser scanners by allowing for higher speeds with reduced peak position and circularity error.

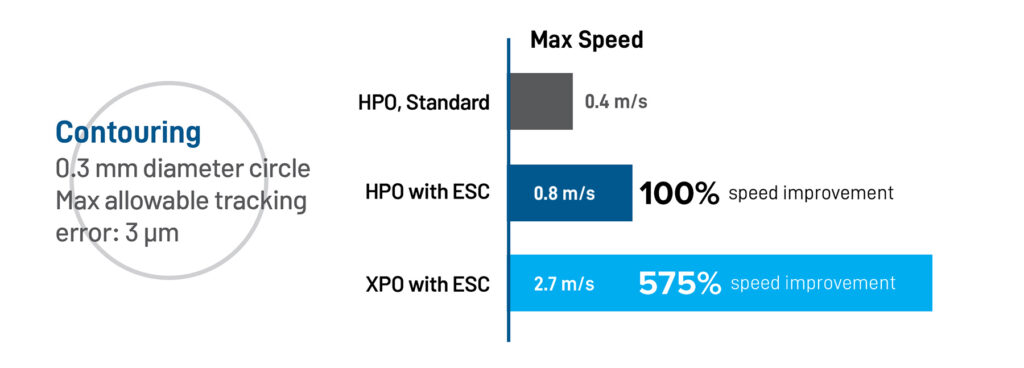

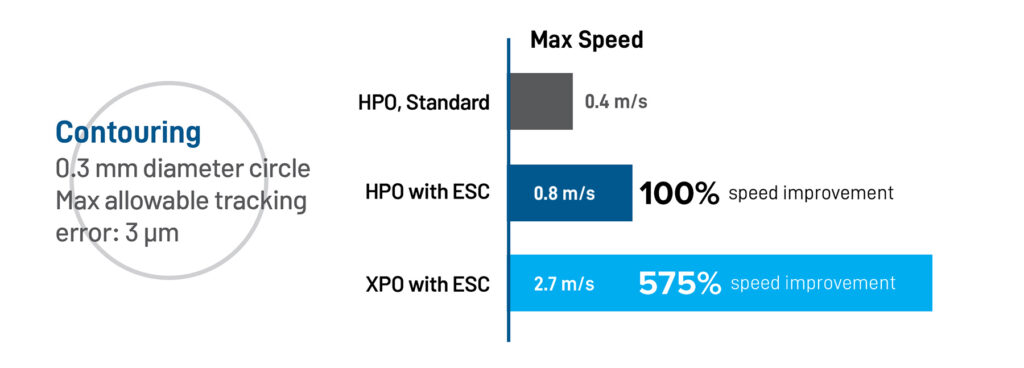

To quantify the maximum possible speed for the AGV-HPO (with and without ESC enabled) and AGV-XPO (with ESC enabled), each completed an example profile for a 0.3 mm diameter circle with a peak position error of 0.003 mm. As shown in Figure 3, the AGV-HPO baseline without ESC was limited to 0.4 m/s before it began exceeding the peak position error. With ESC enabled, however, the AGV-HPO reached speeds of 0.8 m/s – a 100% improvement. Comparing the AGV-HPO without ESC to the AGV-XPO with ESC enabled resulted in a 575% improvement in speed, as the AGV-XPO with ESC reached 2.7 m/s before exceeding the 0.003 mm error limit.

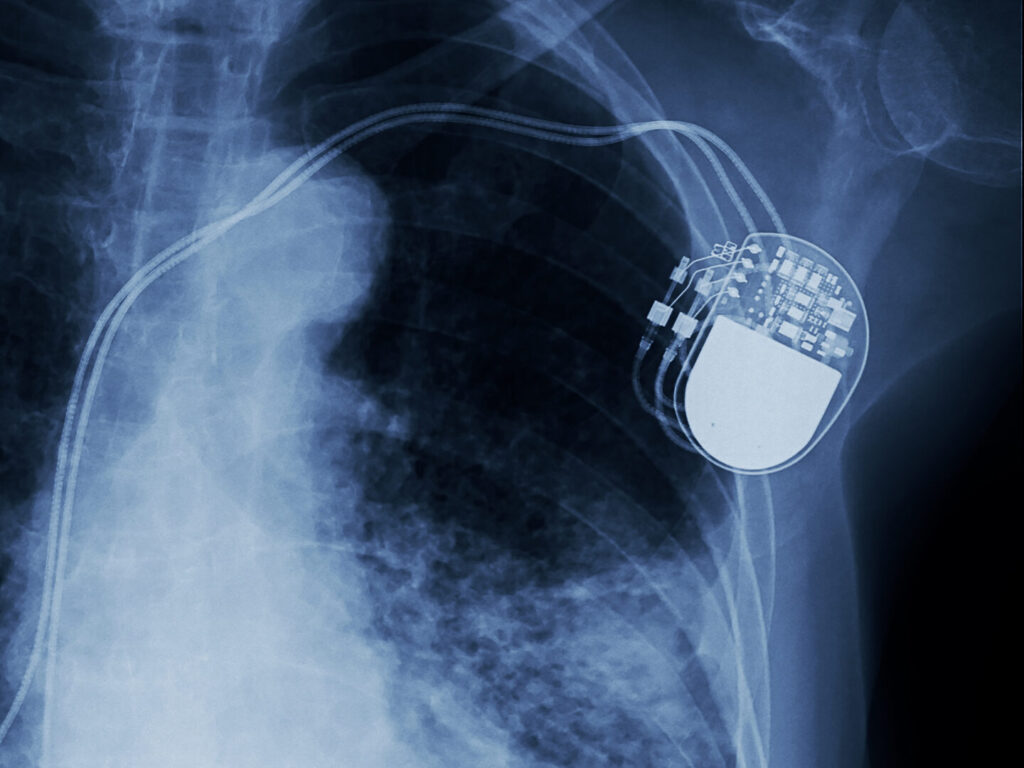

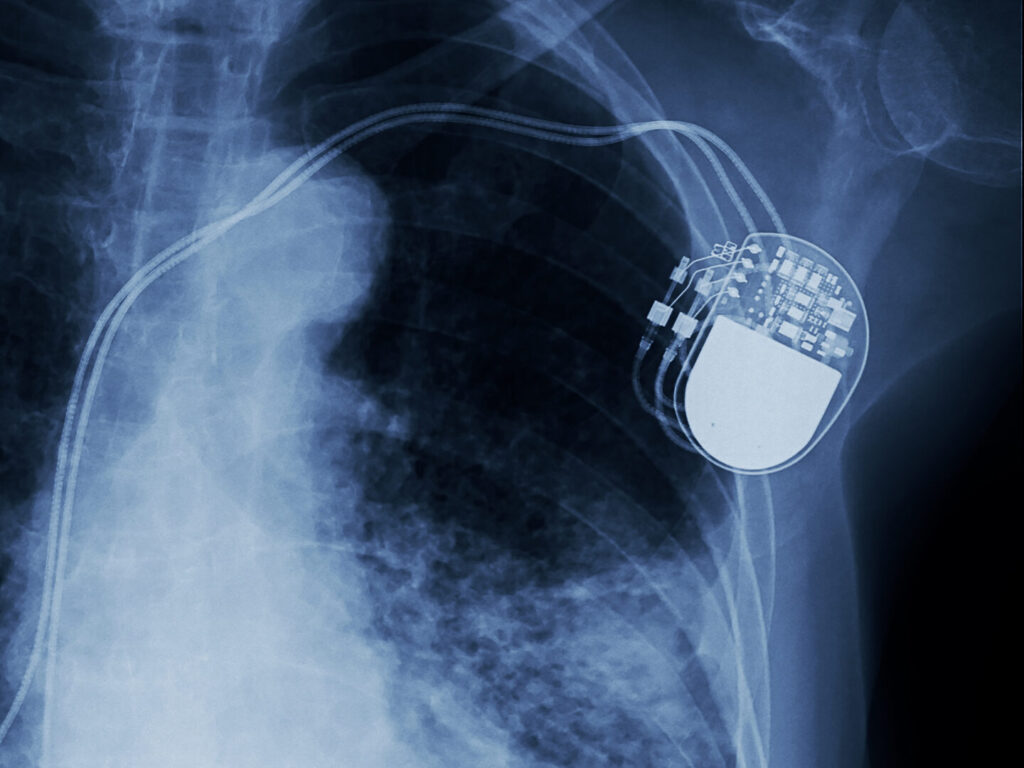

This improvement boosts productivity and ensures the geometric integrity of circular contouring at higher speeds – improving the resultant quality for many applications. This is valuable in medical device manufacturing, especially the production of cardiac rhythm management (CRM) devices (also known as pacemakers), pictured in Figure 4. Manufacturing CRM devices requires tight control of laser tracking for specific features to ensure optimum product quality and efficacy.

Applications that will benefit from enhanced circular contouring performance include:

- Pacemaker hermetic seal welding (medical device manufacturing)

- Microfluidic device manufacturing (medical device manufacturing)

- Laser cutting of mobile and automotive device displays (electronics manufacturing)

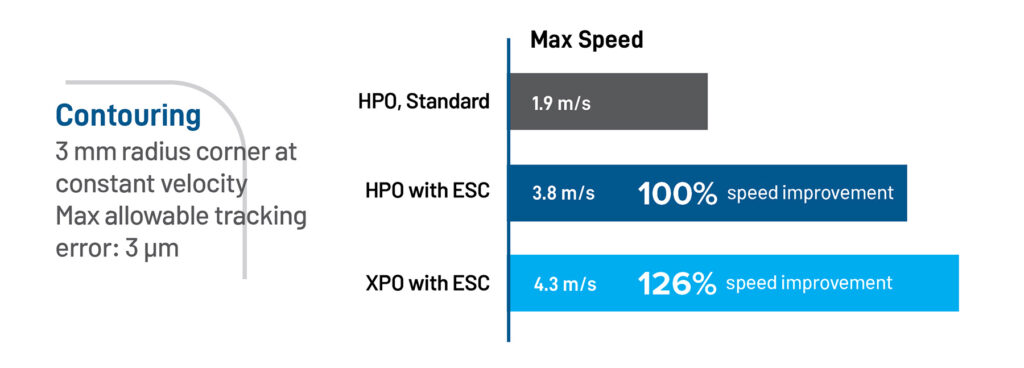

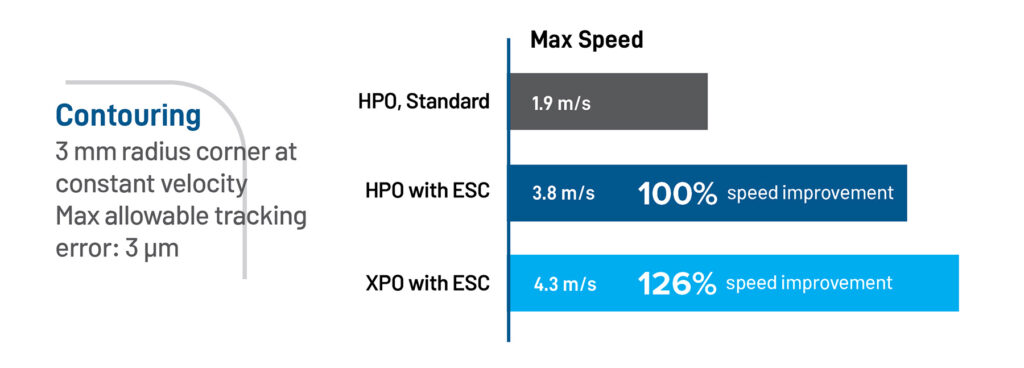

Benefits for Vector Contouring Motion

Vector-based contouring motion is a common motion profile used in many laser applications such as glass cutting. Vector motion involves navigating a complex series of points that define the motion path at high speeds without exceeding an application-specific maximum allowable tracking error. With ESC enabled, laser scan heads can achieve faster contouring speeds without those limits.

To demonstrate this, the AGV-HPO (with and without ESC enabled) and AGV-XPO (with ESC enabled) completed a profile with a 0.3 mm radius and maximum allowable tracking error of 0.003 mm. As depicted in Figure 5, the AGV-HPO without ESC performed this move at 1.9 m/s before the peak position error exceeded 0.003 mm. However, with ESC enabled the same product performed this move at 3.8 m/s before exceeding the limit, representing a 100% improvement. The AGV-XPO with ESC enabled performed this motion at 4.3 m/s, representing a 126 % improvement over the AGV-HPO without ESC.

Faster contouring speeds are especially advantageous in high-volume mobile display manufacturing, shown in Figure 6, because the part volumes can easily exceed 100 million units per year for a single display type.

By using ESC, these manufacturers can see 100-125% improvement in cycle time for a single display cutting operation. Enabling this improvement for the millions of parts manufactured will yield a significant productivity boost.

Applications that will benefit from enhanced vector contouring performance include:

- Display cutting (electronics manufacturing)

- Orthodontic aligner trimming (medical device manufacturing)

- CNC laser milling (general micromachining)

Summary

Enhanced Scanner Control (ESC) is an advanced real-time control algorithm that passively improves the performance of all motion – most notably impact step and settle, high frequency contouring and vector contouring motion for all laser applications. This directly translates to increased productivity for Aerotech’s AGV laser scan head users, who will see faster cycle times and improved overall process quality. It also eliminates the notion that increased speed comes at the expense of part quality.

For industries where precision laser processing precision is non-negotiable, ESC offers a competitive edge as it delivers increased throughput, reduced cycle times and higher quality laser-processed products.