ABRS Air-Bearing Direct-Drive Rotary Stage

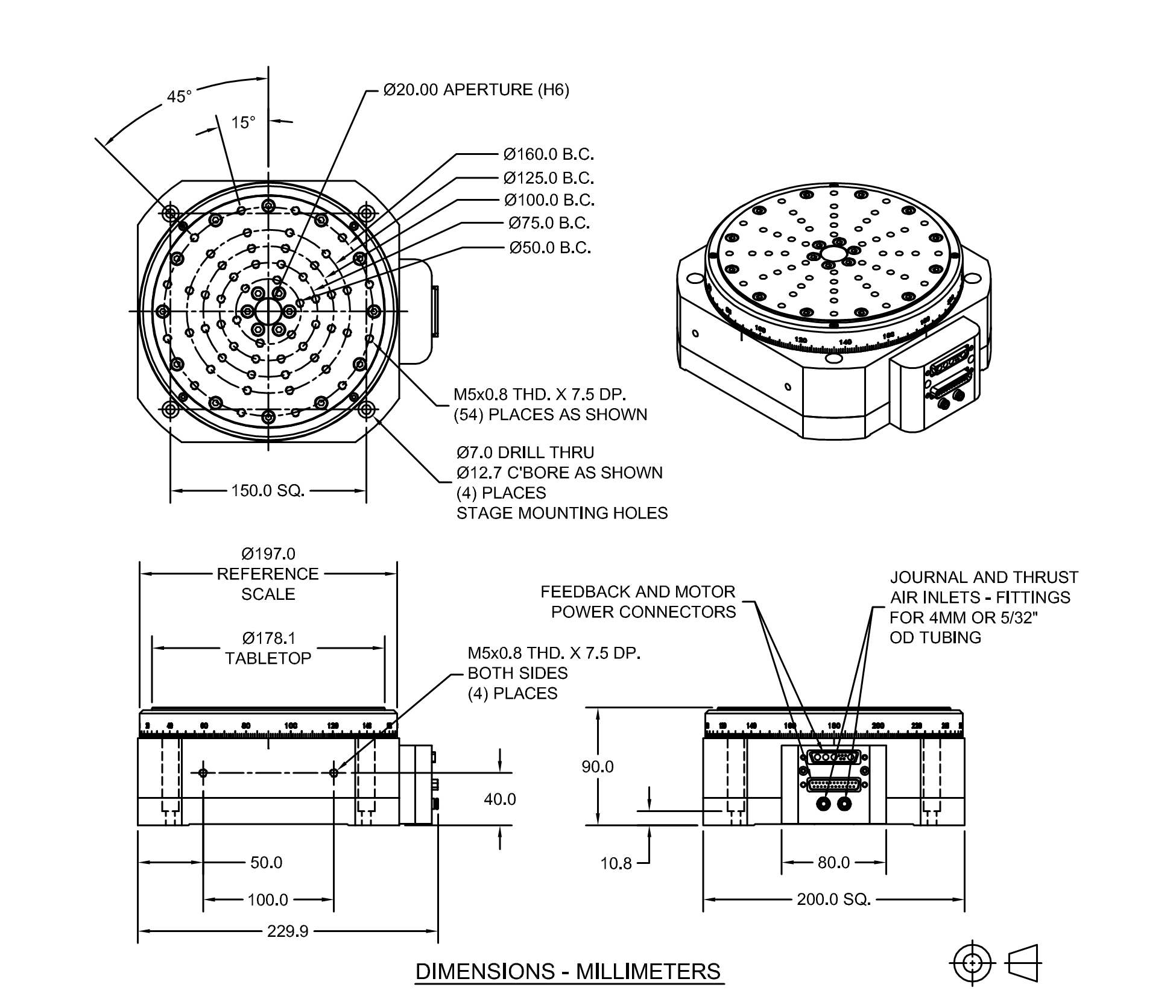

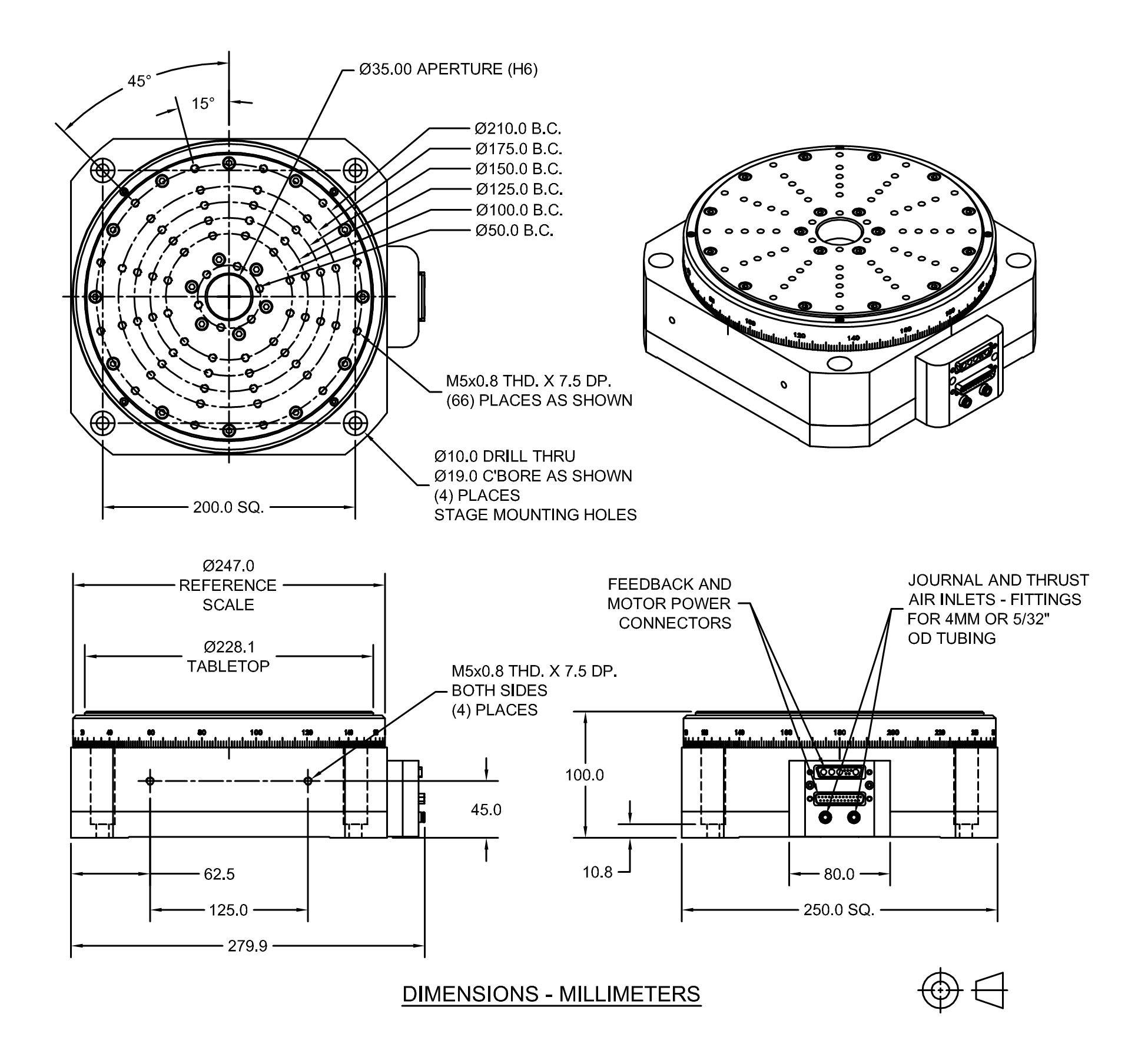

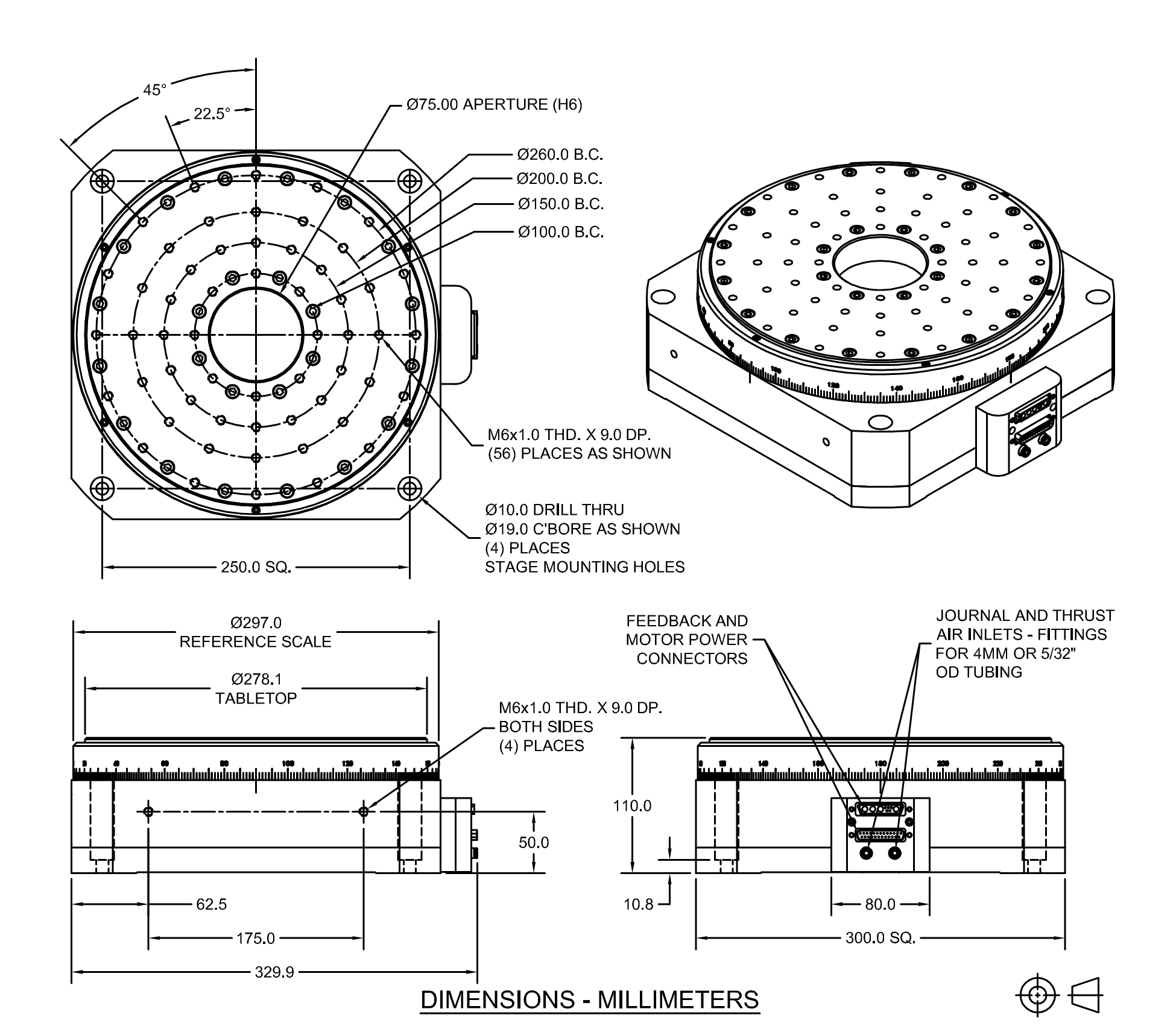

ABRS direct-drive rotary air-bearing stages deliver superior angular positioning, velocity stability and error-motion performance in an exceptionally compact package. An ironless, slotless torque motor; high-resolution position encoder; and precision-ground air-bearing surfaces ensure precise, stable and reliable rotary motion. Independent air inlets for journal and thrust bearings maximize this stage’s versatility. Available in 200 mm, 250 mm and 300 mm frame sizes — all featuring ultra-low profiles — ABRS stages provide an optimal balance between performance, size and cost.

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Direct-drive, slotless motor provides smooth, non-cogging motion

- Low-profile design is cost effective & easy to integrate

- Superb axial, radial & tilt error-motion performance

- Clear central aperture provides versatility for product feed-through, beam delivery, cable clearance & more

- Large bearing surfaces for excellent load capacity & stiffness

Key Applications

ABRS is ideal for high-precision test, inspection and manufacturing applications, including:

- Wafer inspection

- Surface metrology (including roundness, flatness & form error)

- X-ray diffraction systems

- CT inspection systems

- Optical alignment, inspection & calibration

- Nanotechnology fabrication

- Beamline research

Compact Package

The design of the ABRS series direct-drive rotary stage has been optimized to minimize stage height. The low profile of the stage reduces the effective working height of the system, minimizing "stack-up" related errors. In addition to the low overall height, the ABRS series provides a clear aperture that can be used for product feed-through, laser beam delivery, cable clearance or application-specific requirements.

Superior Mechanical Design

The ABRS design features large air-bearing surfaces for high stiffness and load capacity, producing not only excellent axial and radial error motions but outstanding tilt error motion, as well. The resultant face error motion is significantly better than other rotary air-bearing tables and spindles, greatly benefiting applications requiring exceptional planar performance.

Brushless Direct-Drive

To maximize positioning performance, the ABRS series utilizes Aerotech’s S-series slotless, brushless motor. The motor uses an advanced magnetic circuit design to produce high torque output with minimal heat generation. The slotless design is inherently zero-cogging and torque ripple-free. This makes ABRS stages ideal for applications requiring smooth scan velocities at low or high speeds.

Accurate Positioning

An optical encoder is standard with the ABRS. When coupled with Aerotech's feedback multipliers and controls, resolutions of <0.03 arc second are achievable.

Custom Designs

Custom versions of the ABRS are available for rate table and inertial guidance test-stand applications.

Ordering Information

ABRS Air-Bearing Direct-Drive Rotary Stage

| Option | Description |

| ABRS200MP | 200 mm wide air-bearing direct-drive rotary stage |

| ABRS250MP | 250 mm wide air-bearing direct-drive rotary stage |

| ABRS300MP | 300 mm wide air-bearing direct-drive rotary stage |

Feedback (Required)

| Option | Description |

| -E1 | Incremental encoder, 1 Vpp |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |