WaferMaxT Mechanical-Bearing Direct-Drive Rotary Stage

WaferMaxT meets the extreme precision and throughput demands of cutting-edge wafer processing applications. Its ironless motor provides ultra-smooth, high-dynamic motion free from parasitic forces. Outstanding geometric performance minimizes axial-, radial- and tilt-error motions, helping to ensure superior process stability. Its high-stiffness yet low-profile design – with a large, clear aperture and optional rotary union – simplifies integration into compact, high-performance systems and machines. Choose WaferMaxT to improve process capability, increase throughput and maximize yield in critical wafer processing applications.

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

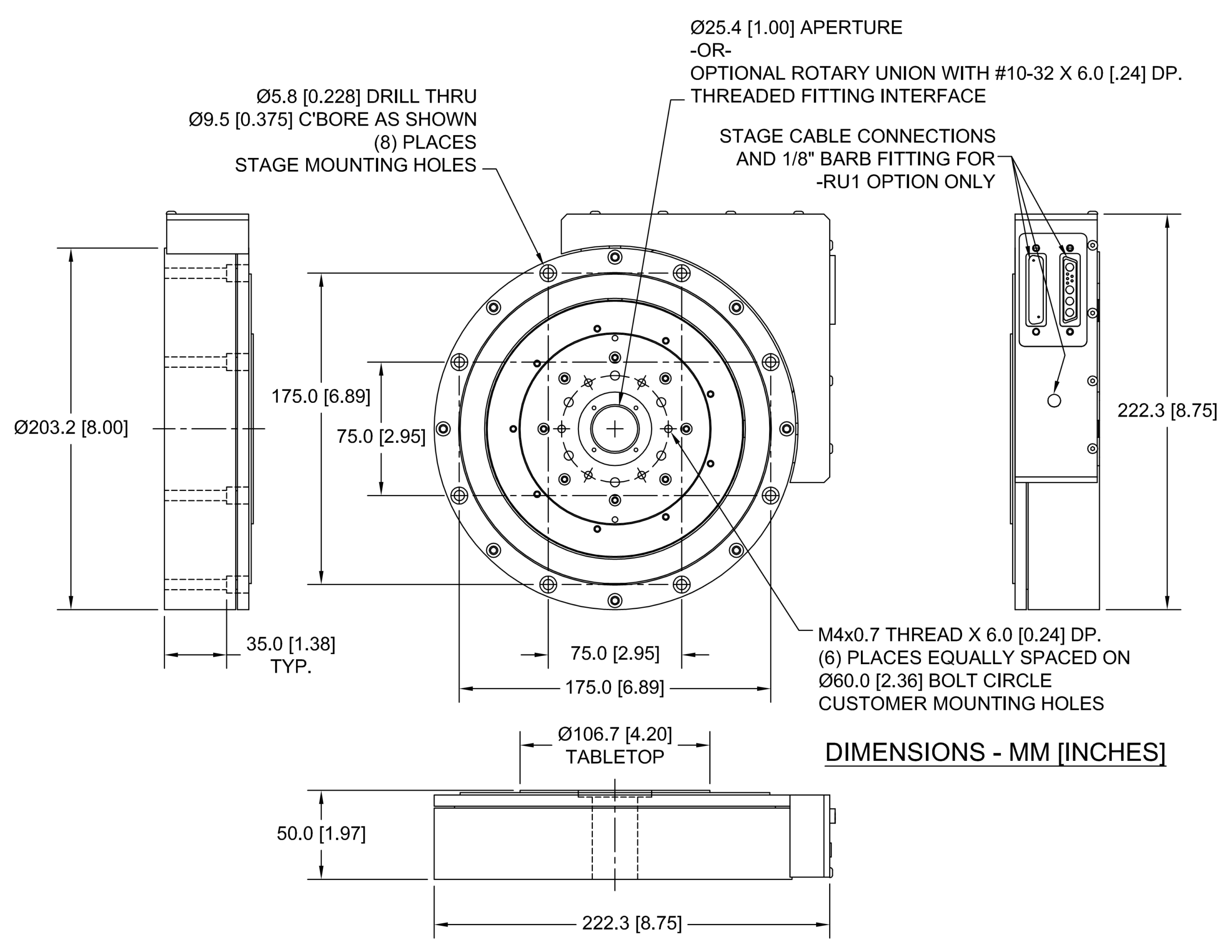

Dimensions

Ordering Info

Downloads

Description

Design Features

- Superior mechanical architecture maximizes throughput & minimizes error motions

- Ironless motor delivers smooth motion with exceptional dynamic capabilities

- Low-profile design for space-constrained applications eases assembly & integration

- Optional single-port rotary union provides easy-access pneumatic service to wafer chucks

- Combines effortlessly with WaferMaxZ to create a compact & effective Z-Theta solution

Key Applications

WaferMaxT is ideal for wafer processing applications and more, including:

- Wafer inspection & metrology

- Advanced packaging

- High-precision wafer handling & orientation

- Photolithography & mask/reticle alignment

- Photonic Integrated Circuit testing

Superior Mechanical Design

Angular contact bearings are used to maximize performance with respect to wobble, moment stiffness and rotating friction. A thick-walled, precision-ground shaft further minimizes wobble.

Cable management is a snap with integral motor power and feedback connectors. Because the WaferMaxT is a self-contained unit, it can be integrated easily into multi-stage stacks. Either a service loop or an integrated Aerotech cable management system (CMS) can be provided for a highly reliable solution.

Brushless Direct-Drive

To maximize positioning performance, the WaferMaxT utilizes Aerotech’s S-series brushless, slotless motor. This motor has all of the advantages of a brushless direct-drive motor — no brushes to wear, no gear trains to maintain and high acceleration and high speeds. Since it is a slotless, ironless design, there is zero cogging, meaning that there is absolutely no torque ripple. This makes the WaferMaxT ideal for applications requiring outstanding contoured motion, smooth scan velocity or precise incremental steps. The low inertia and zero backlash make the WaferMaxT the ideal solution for applications requiring frequent directional changes.

Accurate Positioning

Performance is guaranteed with a high-resolution encoder that results in ultra-fine resolution. The motor and encoder are directly coupled to a common shaft, eliminating errors due to backlash and windup.

Flexible Configurations

Aerotech manufactures a wide range of servo amplifiers and advanced controllers to provide a complete, integrated package.

Ordering Information

WaferMaxT Direct-Drive Rotary Stage

| Option | Description |

| WaferMaxT | Direct-Drive Rotary Stage with 25 mm Clear Aperture |

Feedback

| Option | Description |

| -E3 | Incremental encoder, 10052 lines/rev, 1 Vpp |

WaferMaxT Options

| Option | Description |

| -RU1 | Single-port rotary union for air/vac feed-through |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |