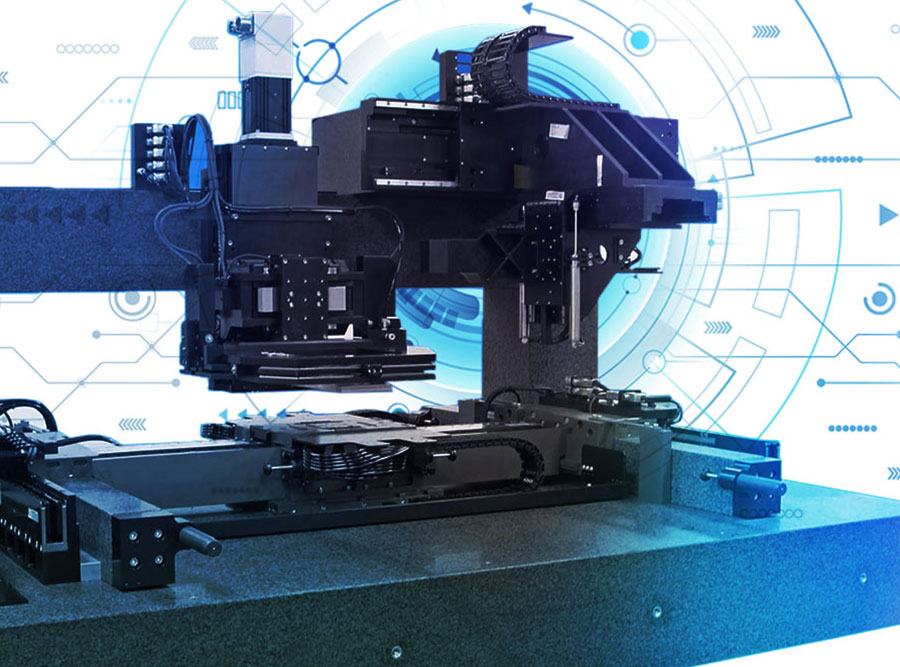

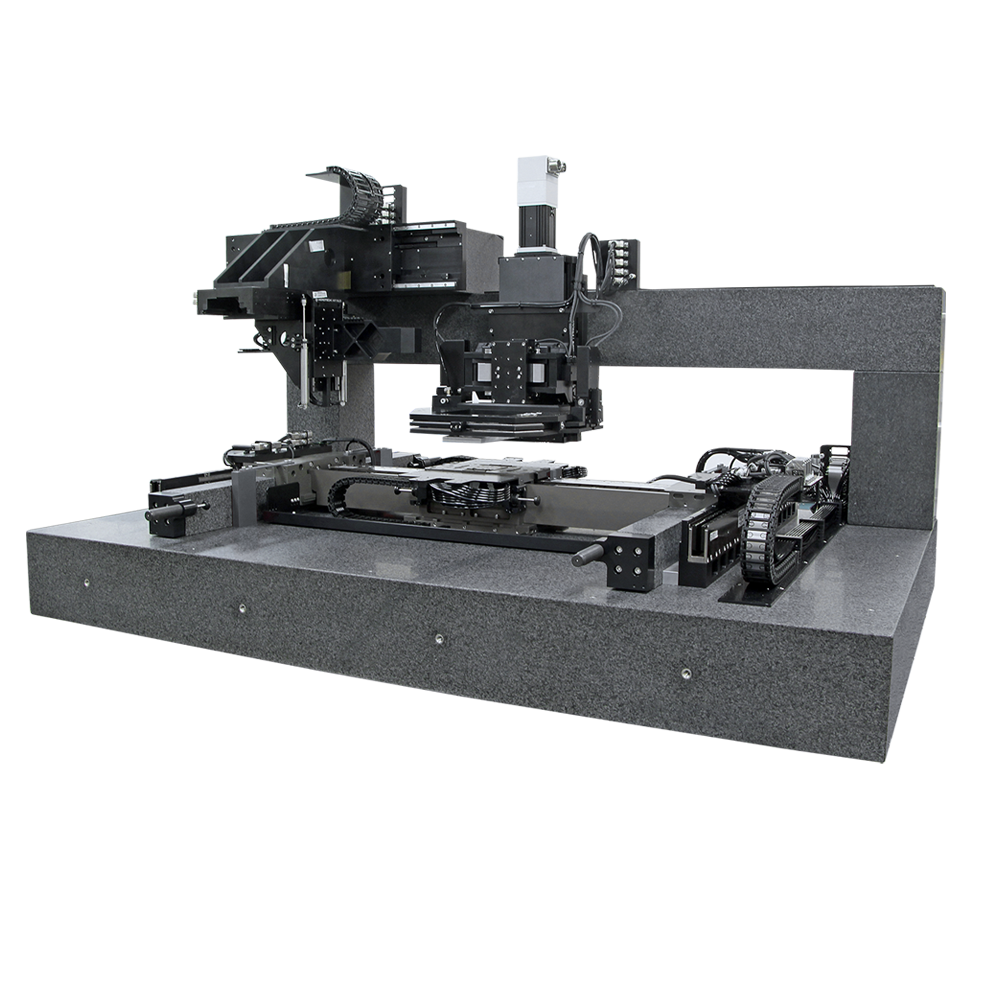

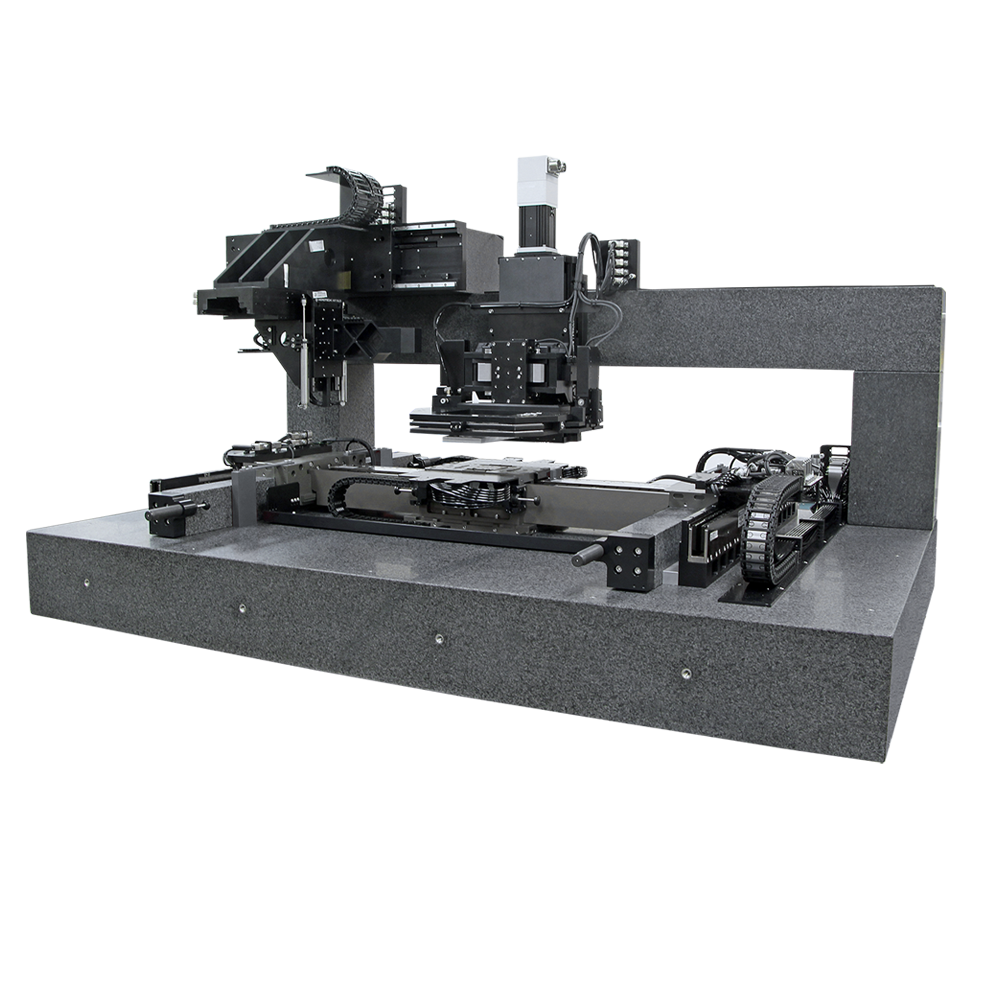

ADVANCED PACKAGING

Next-generation bonding enabled by nanometer-level precision.

We deliver the exceptional alignment precision you need for high-yield, high-throughput bonding processes.

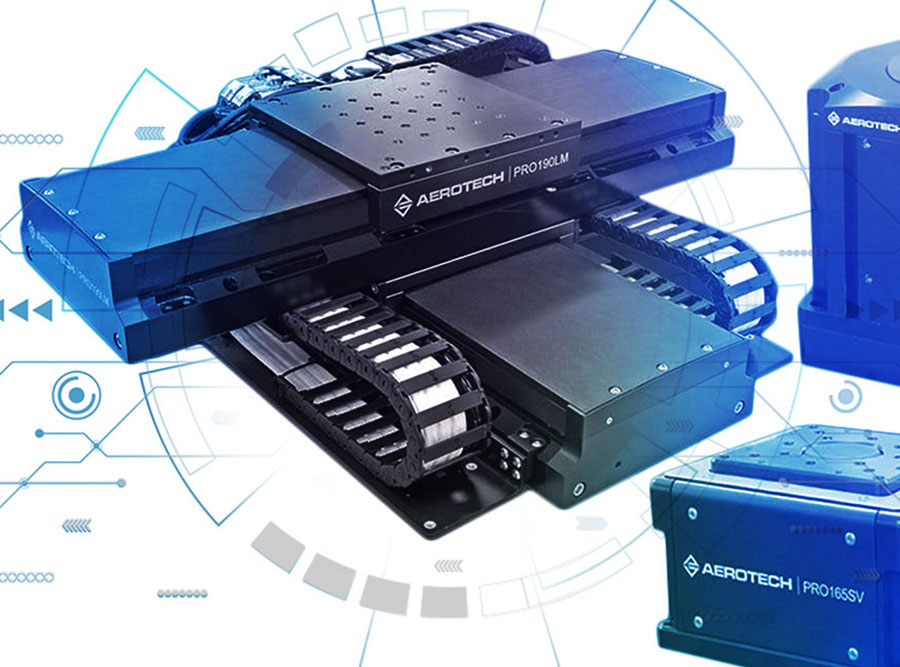

Nanometer-Level Precision for Critical Alignments

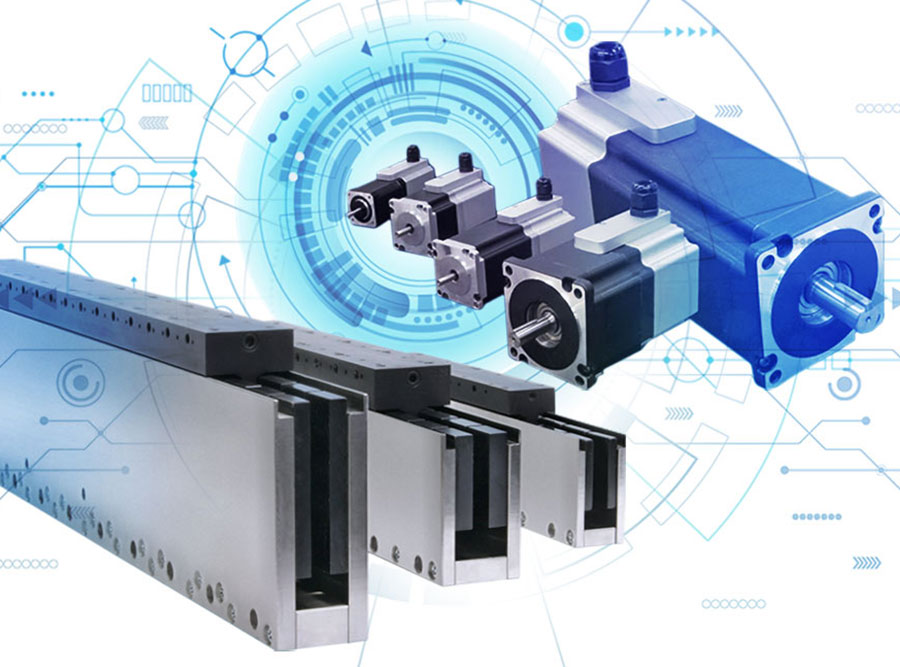

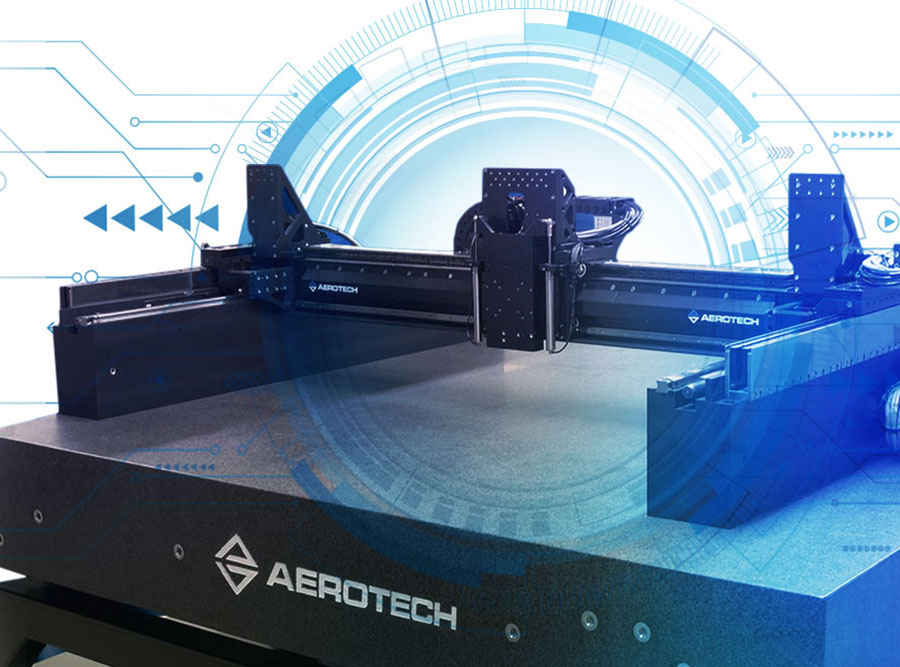

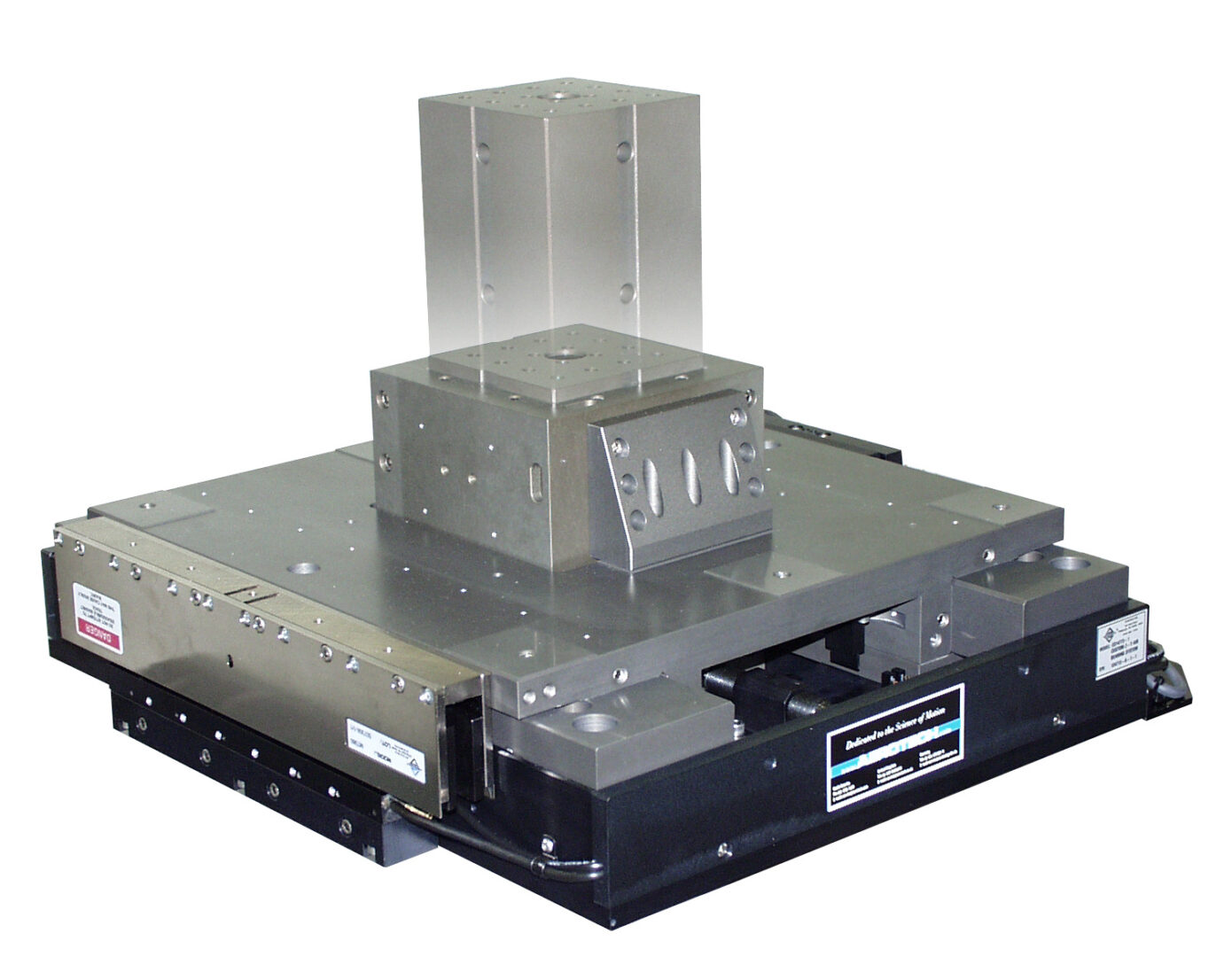

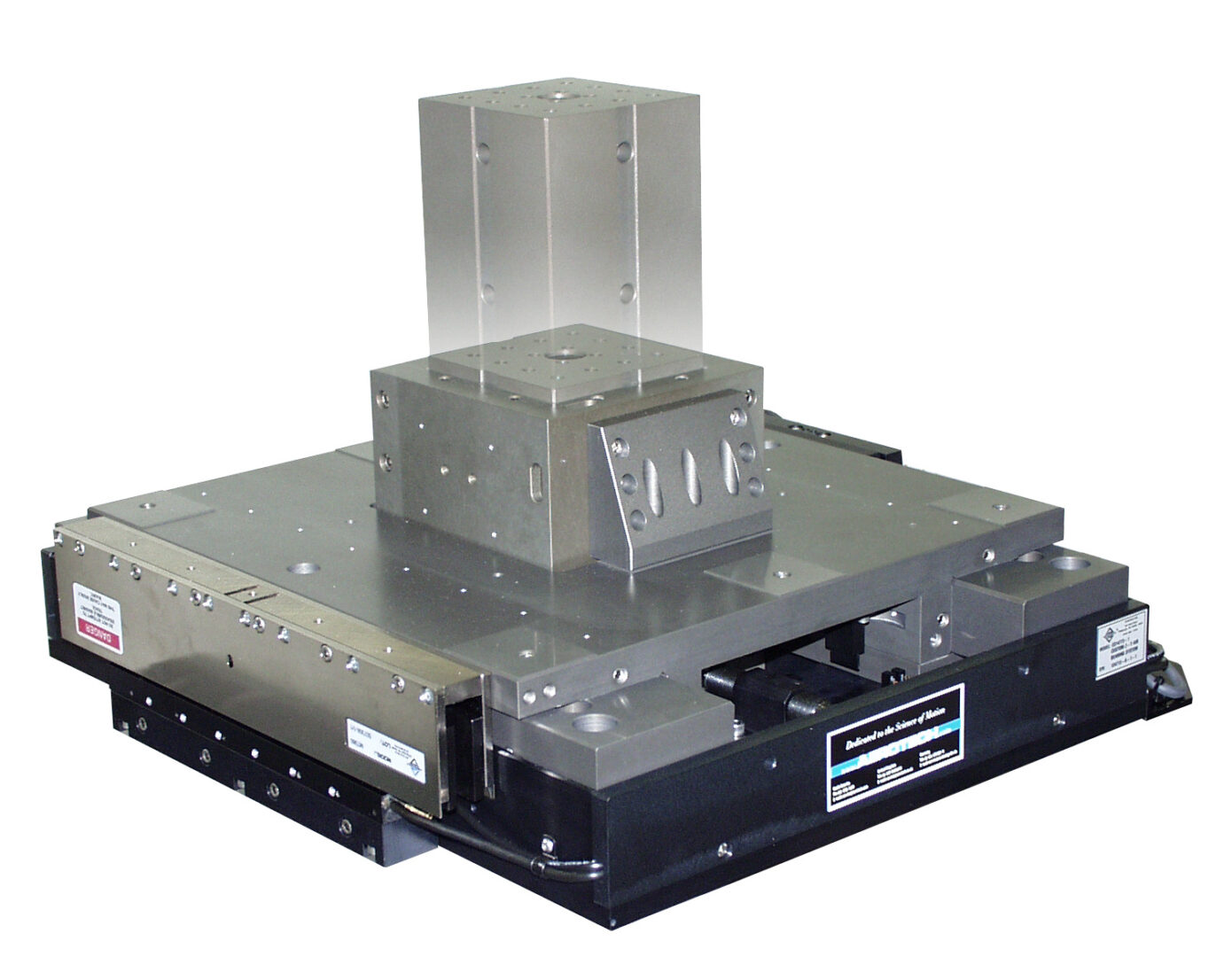

To achieve flawless bonds in advanced packaging, you need nanometer-level positioning accuracy plus arcsecond-level angular alignment and planarity. Our motion systems deliver the exceptional geometric performance you need — in all six degrees of freedom — to align dies and wafers and address the shrinking pitch demands of advanced hybrid bonding processes.

Advanced Controls Maximize Precision & Throughput

Achieving high throughput for delicate advanced packaging processes like hybrid bonding requires precise Z-axis force control, single-digit nanometer position stability and rapid step-and-settle performance. Combining integrated force feedback, advanced isolation systems, novel position-locking capabilities, superior stage dynamics and stiffness-optimized mechanics, we ensure your system meets quality and throughput targets.

Engineered for Ultra-High Vacuum & Cleanroom Environments

Advanced packaging processes require stringent environmental control. We perform integration and metrology in our 6,500 ft2 cleanroom with ISO Class 5 capability, qualifying our systems for use in demanding cleanroom and ultra-high vacuum (UHV) fabrication settings.