GANTRIES

High-performance gantries for inspection and manufacturing.

When your application demands high accuracy, repeatability, throughput and precision, Aerotech gantries deliver.

Our gantries are trusted worldwide in applications that require high throughput and precision.

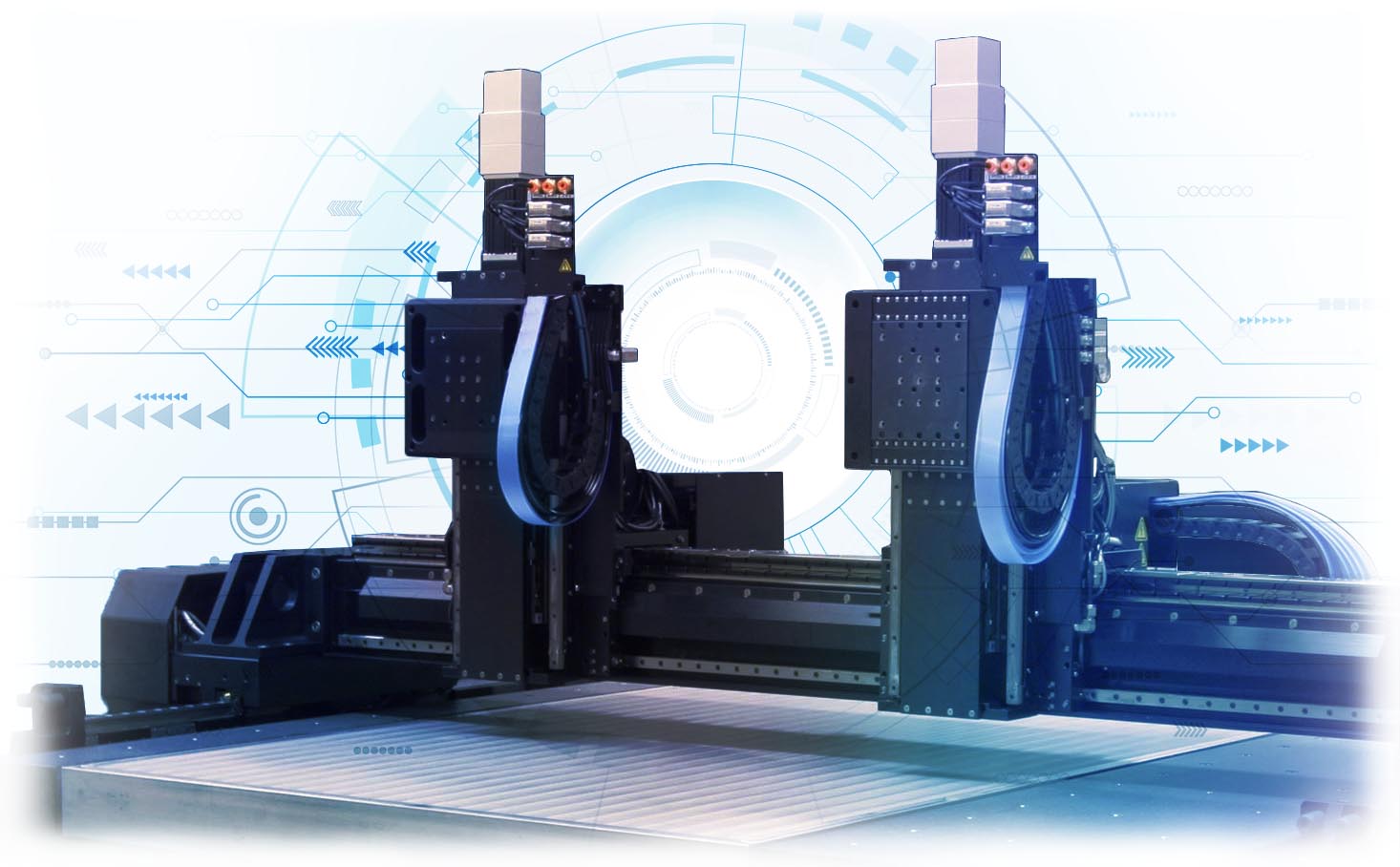

Every Aerotech gantry system relies on our industry-leading brushless linear servo motors and delivers the highest performance for applications like precision assembly, micromachining, optical inspection, flat panel processing, laser material processing and more.

Because we design our systems to use a unified motion controller for all types of motion axes, you’ll easily synchronize all axes of motion and implement your process faster – and with the highest possible degree of accuracy.

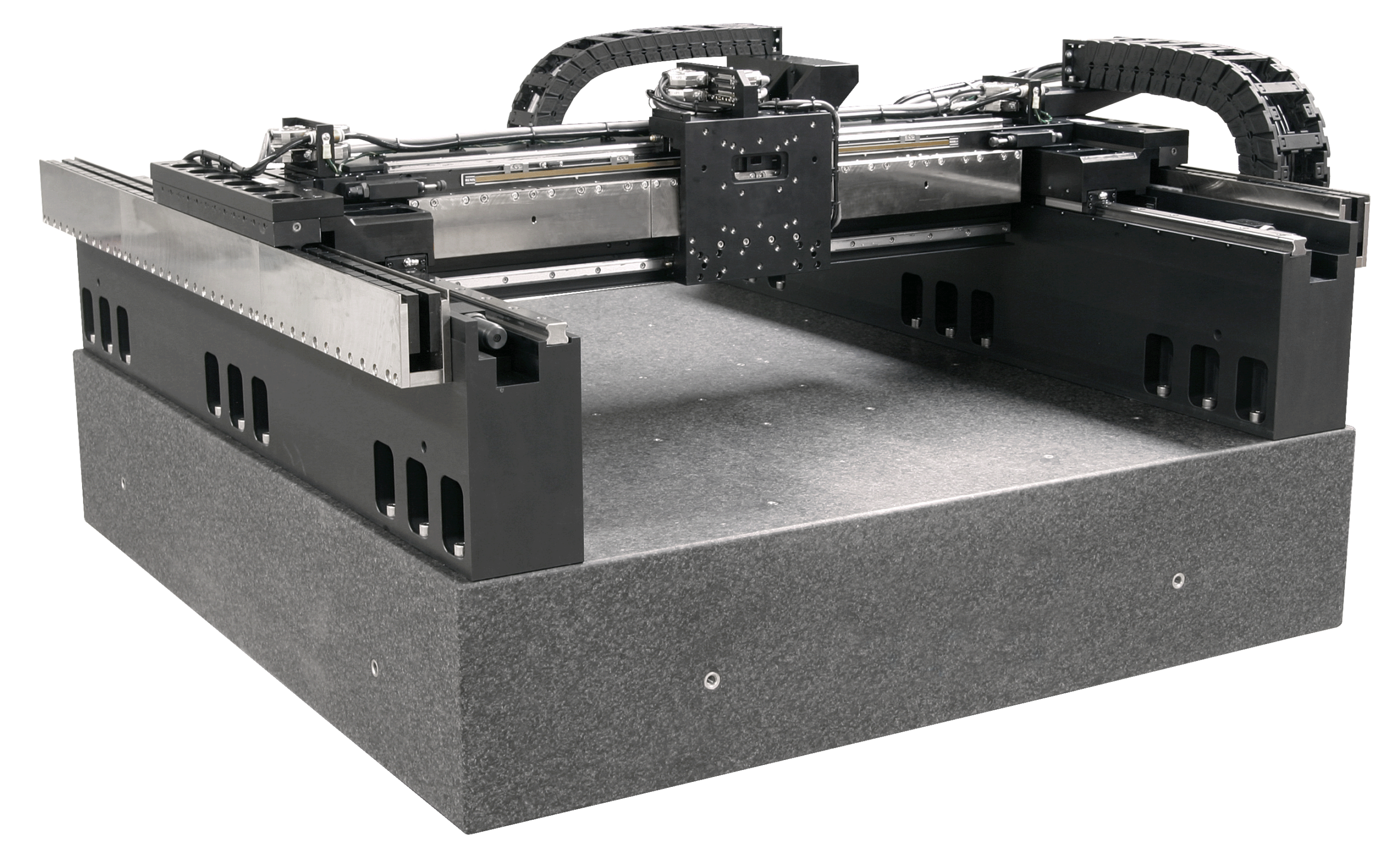

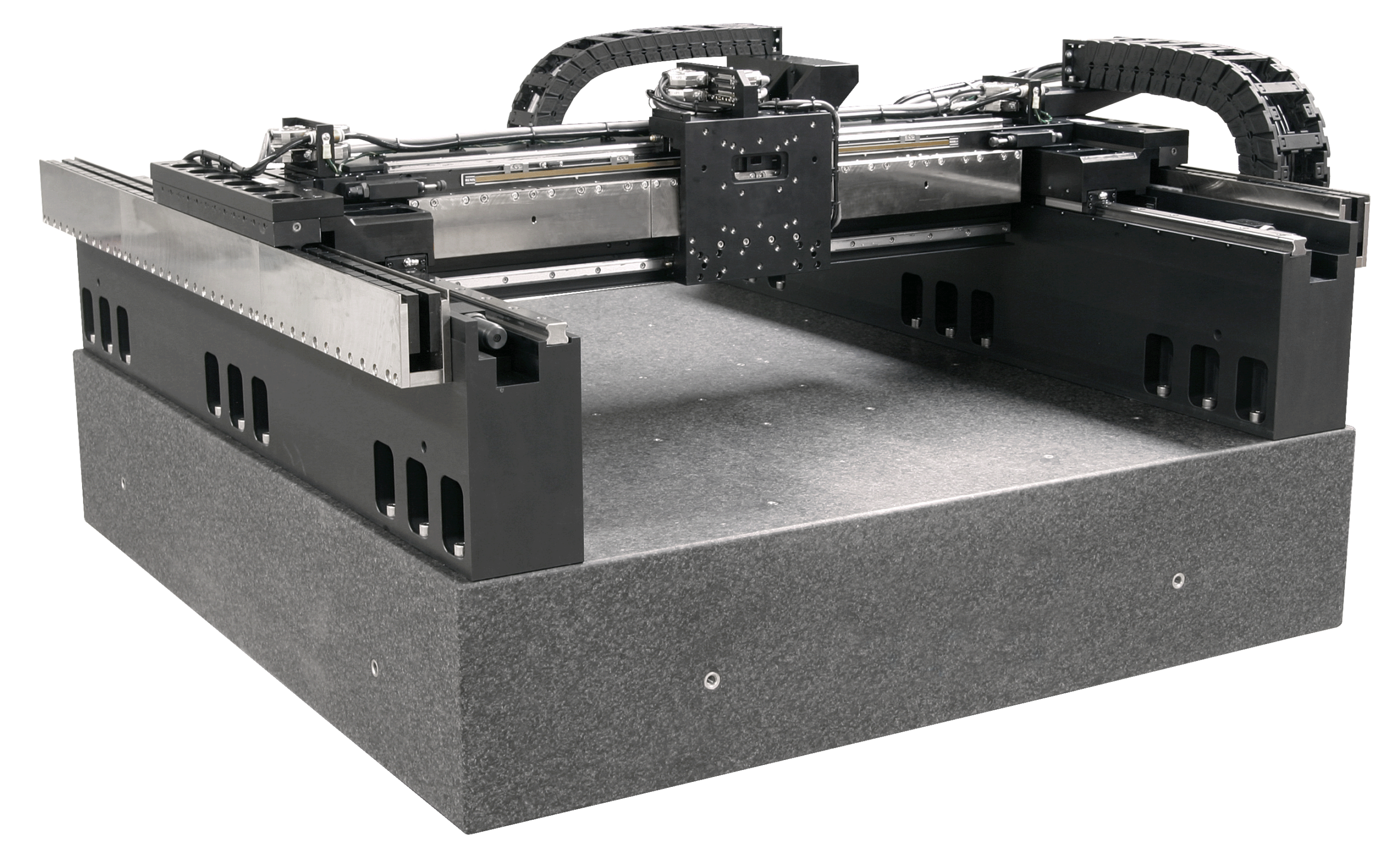

FEATURED PRODUCT

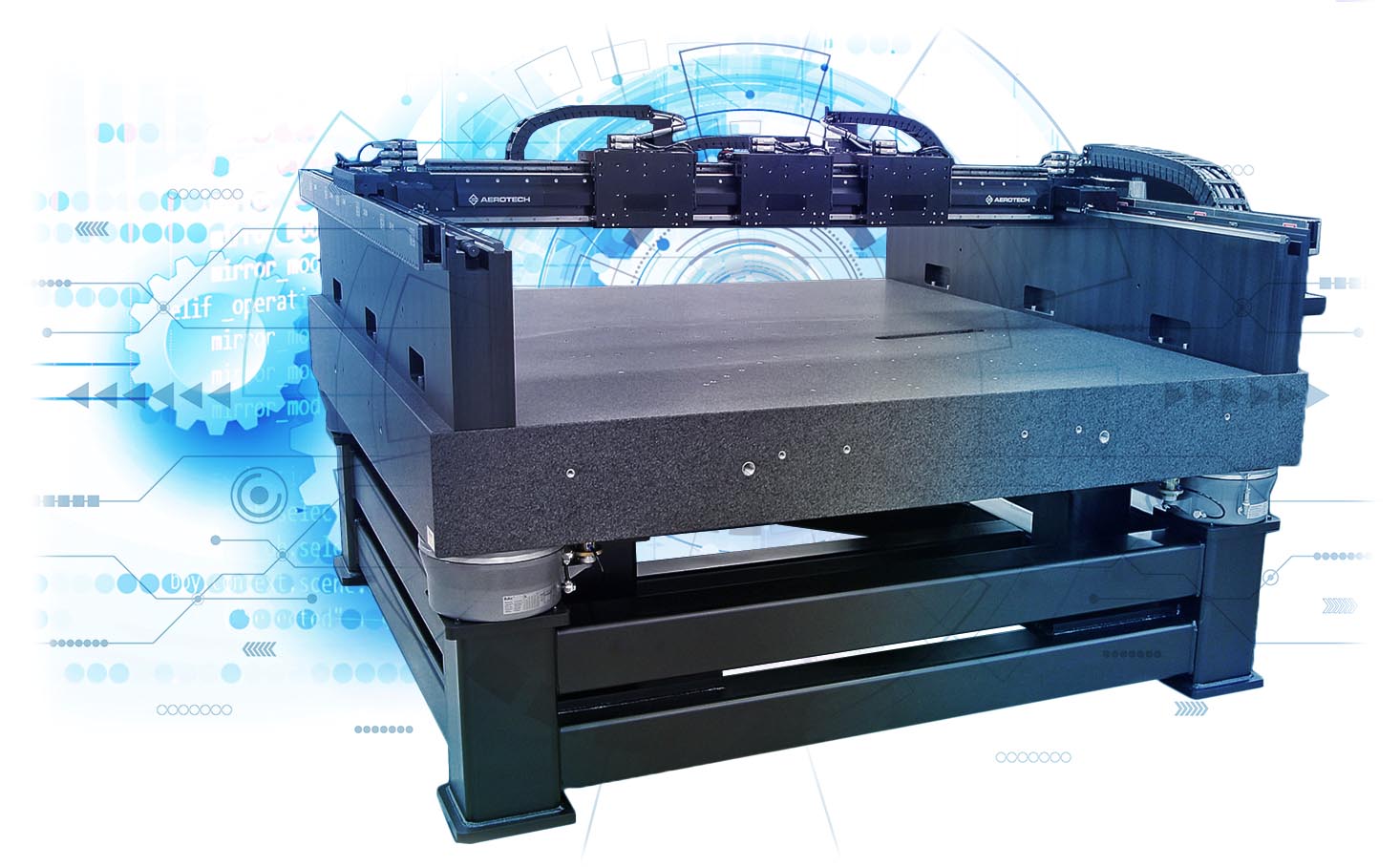

The AGS15000 series is optimized for precise contouring and high accuracy.

Our AGS15000 Cartesian gantry systems are designed for ultra-precise, high-dynamic contouring. Industry leaders worldwide use them for precision micromachining, stencil cutting, fuel cell manufacturing, printed electronics and more.

Maximum Precision

Built with micron-level positioning accuracy and repeatability for 24/7 production operations.

High Dynamics

Designed with high speed, high acceleration and process throughput in mind.

Controller Features

Standard and optional controller features designed specifically for gantries.

Industry-leading Performance

Our Cartesian gantry systems, also known as XY gantry systems, are built to handle high speeds and large payloads without compromising on accuracy, repeatability or throughput. Powerful linear motors enable the highest speed and acceleration available, while encoder feedback and control features like Gantry Mode and the Enhanced Throughput Module maintain precision.

Customized Solutions

From accommodating a wide range of travel sizes – ensuring safe motion that doesn’t compromise on speed, accuracy or throughput – to cable management, machine bases, isolation systems and more, our in-house system design team is ready to create a high-precision gantry solution that meets your precise needs. Contact us to learn how our gantry positioning systems can amplify your industrial automation process.

Resources

Selected Products

AGS1000 Direct-Drive Gantry

The AGS1000 series of Cartesian gantry systems puts Aerotech’s core technologies and extensive manufacturing capability to work for…

View

AGS1500 Direct-Drive Gantry

The AGS1500 series of Cartesian gantry systems is designed for ultra-precision and high-dynamic contouring, providing outstanding performance and…

View

AGS10000 Direct-Drive Gantry

The AGS10000 series of Cartesian gantry systems puts Aerotech’s core technologies and extensive manufacturing capability to work for…

View

Custom Gantries

Aerotech has decades of experience designing and building custom gantries to meet your unique needs. Whether you need…

View