ABG10000 Air-Bearing Direct-Drive Gantry

The ABG10000 air-bearing gantry puts Aerotech’s core technologies and extensive manufacturing capability to work for you, providing outstanding performance and versatility in a wide range of automation applications. These systems are used in applications such as high-speed pick-and-place, automated assembly, vision inspection, dispensing stations and high-accuracy inspection.

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

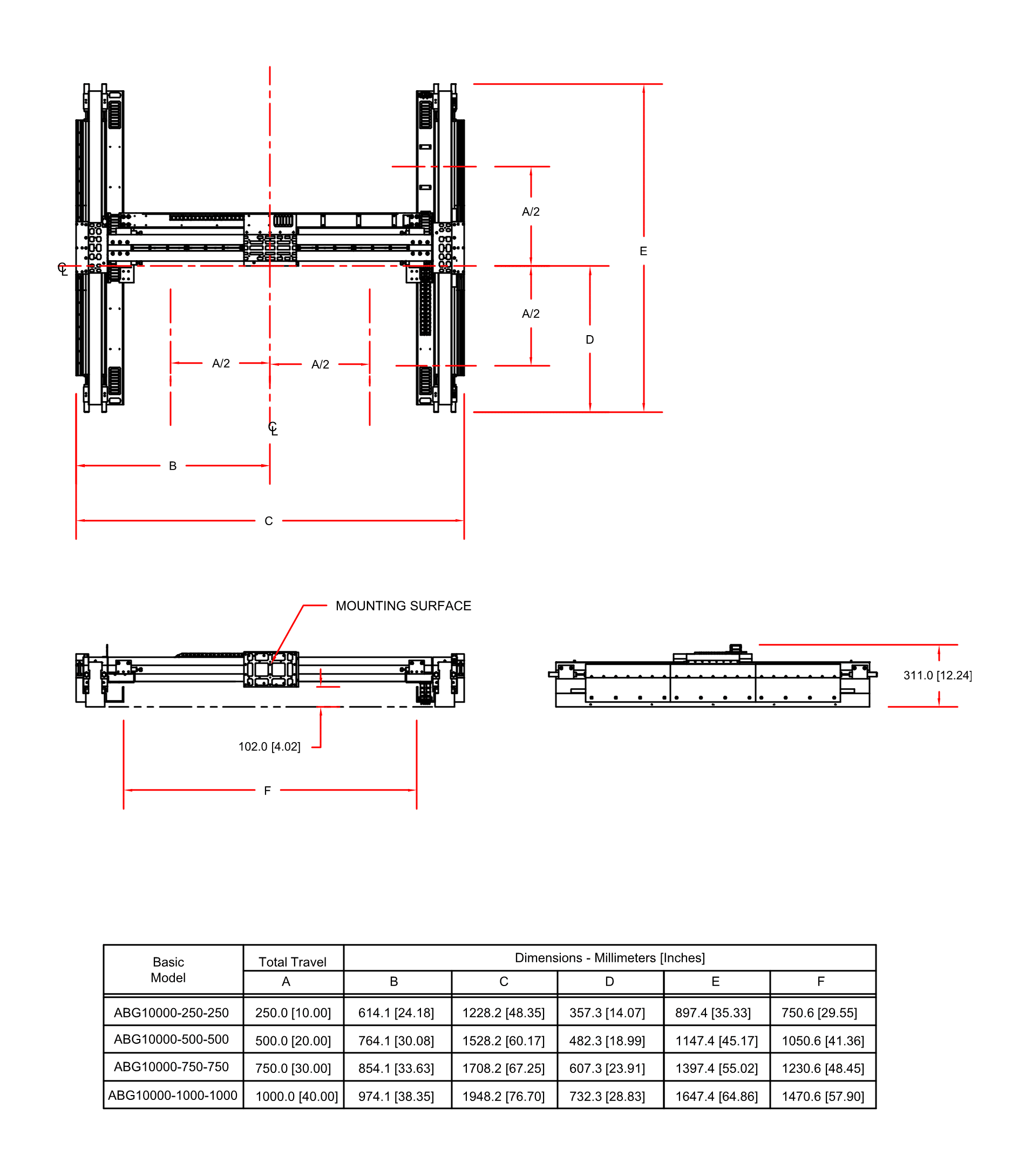

Dimensions

Ordering Info

Downloads

Description

Design Features

- Air bearings for ultra-smooth motion

- All axes are fully preloaded

- Dual linear-motor-driven lower axis

- Travel to 1 m x 1 m

- Options include Z axis, vibration isolation, machine base and control enclosure

The ABG10000 air-bearing gantry puts Aerotech’s core technologies and extensive manufacturing capability to work for you, providing outstanding performance and versatility in a wide range of automation applications. These systems are used in applications such as high-speed pick-and-place, automated assembly, vision inspection, dispensing stations and high-accuracy inspection.

Linear Motor/Linear Encoder

Aerotech’s high-performance BLM series brushless linear servomotors drive the ABG10000 to speeds of 1 m/s and accelerations of 0.5 g. Feedback is from a rugged noncontact optical linear encoder.

Air-Bearing Design

The ABG10000 incorporates an active preload on both vertical and horizontal surfaces. The opposing thin-film pressure maintains the bearing nominal gap tolerance. This design, in addition to the large air-bearing surface that distributes the load over a large surface area, results in a stage with outstanding stiffness that is ideal for heavy or offset loading.

Proprietary manufacturing techniques result in a stage with unsurpassed geometric characteristics. The air bearing has an inherent averaging effect that maximizes performance. The thin film will fill small surface voids and allow for other irregularities. This characteristic yields superior pitch, roll, yaw, straightness and flatness specifications.

Rugged Design

Since the linear motor is a noncontact device there is no backlash, wear or maintenance. The air bearings are magnetically preloaded and assembled to provide optimized stiffness and load distribution.

Cable Management System

Extensive R&D has resulted in an optimized cable management system (CMS) that has been field-proven to be the industry’s most reliable design. Large bend radii and high-flex cables ensure that the air-bearing gantry provides millions of cycles of maintenance-free operation. In the unlikely event of a component failure a modular design ensures that part replacement is fast and easy.

Turnkey Operation

Aerotech’s years of experience manufacturing precision positioning and control systems can be leveraged by acquiring a turnkey system. Typical options include a Z stage, vibration isolation, machine base and a control enclosure. Aerotech also manufactures a wide range of high-performance amplifiers and advanced motion controllers that are optimized for use with the ABG10000.

Custom Designs

Aerotech has engineered and manufactured custom high performance systems to meet customers’ needs and specifications for a variety of applications. We can draw on our vast motion control and positioning system experience to produce the ideal solution for your application.

Ordering Information

ABG10000 Air-Bearing Direct-Drive Cartesian Gantry System

| Option | Description |

| AGS10000-xxxx-yyyy | ABG10000 air-bearing direct-drive cartesian gantry system, XXXX mm lower-axis travel, YYYY mm upper-axis travel |

Feedback (Required)

| Option | Description |

| -E1 | Lower axis: dual incremental linear encoders; 1 Vpp amplified sine output (one per spar)

Upper axis: single incremental linear encoder; 1 Vpp amplified sine output |

| -E2 | Lower axis: dual high-accuracy incremental linear encoders; 1 Vpp amplified sine output (one per spar)

Upper axis: single high-accuracy incremental linear encoder; 1 Vpp amplified sine output |

Limits (Required)

| Option | Description |

| -LI1 | Normally-closed end-of-travel limit switches, 5 VDC |

| -LI2 | Normally-open end-of-travel limit switches, 5 VDC |

Metrology (Required)

| Option | Description |

| -PL2 | Standard performance - includes plots for accuracy and straightness/flatness |

| -PL6 | Standard performance - includes plot for accuracy only |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system

Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components

Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

Accessories (to be ordered as separate line item)

| Option | Description |

| ABF | Air bearing filtration kit |