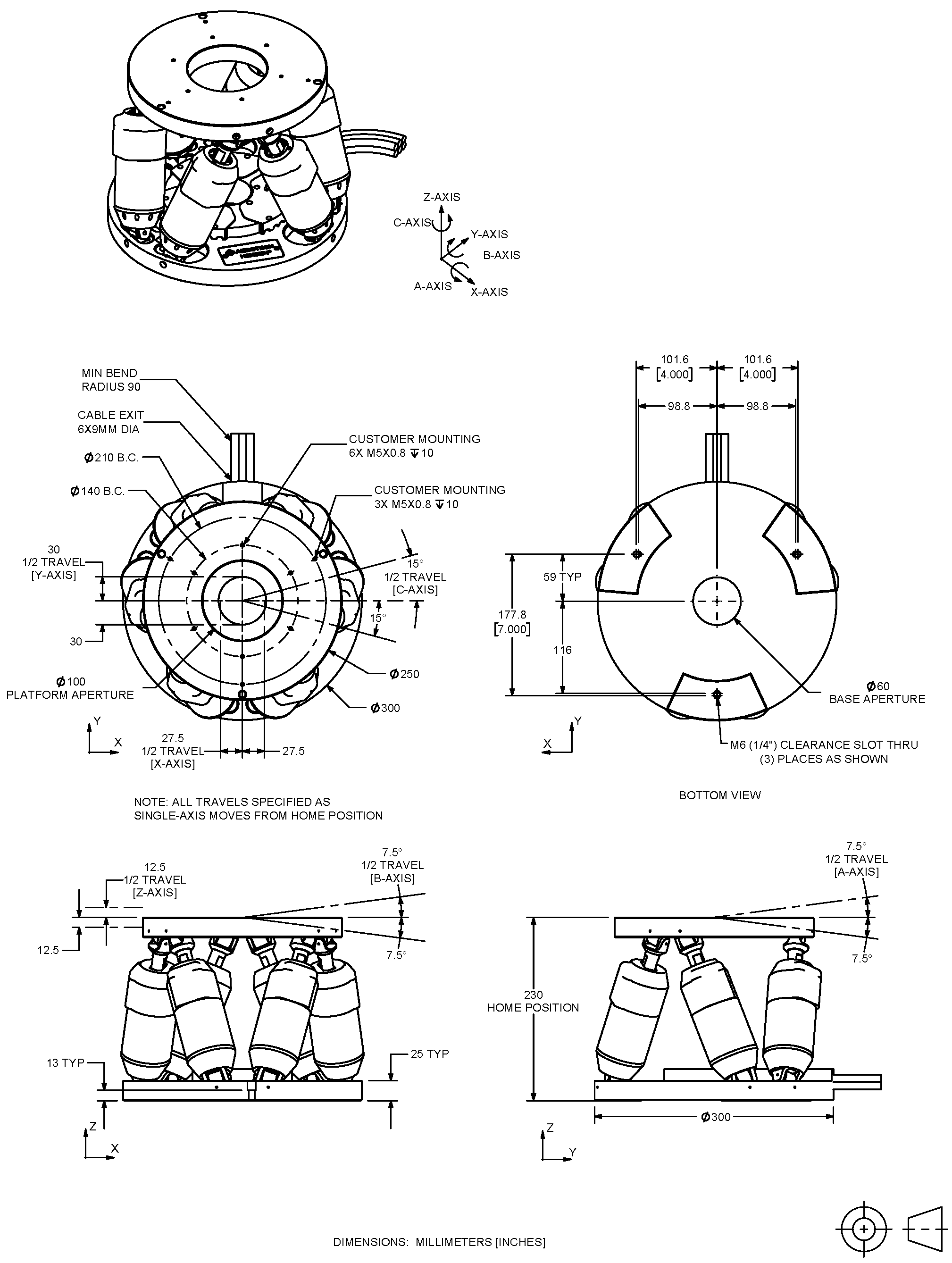

HexGen HEX300-230HL Hexapod Six-DOF Positioning System

Aerotech’s HexGen® hexapods represent the next-generation in six degree-of-freedom (DOF) positioning performance. The HEX300-230HL is the premier medium-load, ultra-precision hexapod for many applications ranging from sensor testing to synchrotron sample manipulation.

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Six degree-of-freedom positioning with linear travels to 60 mm and angular travels to 30°

- Precision design with guaranteed positioning accuracy specifications

- Minimum incremental motion to 20 nm in XYZ and 0.2 μrad in θxθyθz

- Flexible configurations and customization

- Vacuum preparation available upon request

- Powerful controls and software with visualization of work and tool coordinate systems

Performance Unique to the Market

Many trade-offs exist in the design and specification of a motion system. With its high speeds and sub-micrometer precision, the HEX300-230HL eliminates compromises on application specifications. Aerotech’s HexGen hexapods are the only hexapods on the market today that provide guaranteed positioning accuracy specifications below 5 μm.

Superior Structural Design

The HEX300-230HL is actuated with six high-accuracy struts built with precision preloaded bearings, ball screws, and drive components. Unlike competitive hexapods driven by DC brushed servomotors, the HEX300-230HL is driven by Aerotech’s AC brushless, slotless servomotors that maximize device lifetime and performance. Directly coupling the AC brushless servomotors to the ball screw enables increased drive stiffness, higher positioning accuracy, and better minimum incremental motion (20 nm in XYZ and 0.2 μrad for θxθyθz) when compared to competitive designs using belts, gearheads, or compliant couplings. Specially engineered strut pivot-joints provide low friction and high stiffness enhancing the overall hexapod performance.

Design Flexibility

The HEX300-230HL’s design optimizes flexibility and customization options for the user. The platform and base can be easily modified with user-specific features or mounting patterns. The HEX300-230HL features a 100 mm diameter clear aperture in the platform while a 60 mm diameter clear aperture in the base allows workpiece access from the bottom. The base mounting holes adapt directly to English or metric optical tables.

Vacuum Options Available

Aerotech hexapods can be vacuum prepared for demanding applications such as synchrotron sample or optics manipulation, semiconductor manufacturing and inspection, or satellite sensor testing.

Powerful Controls and Software

Driving the HEX300-230HL is Aerotech’s Automation1 Software-Based Machine Controller. Built on years of experience in difficult kinematics applications, the Automation1 controller allows simple programming and control of the hexapod in multiple user-defined coordinate systems with an intuitive interface and real-time motion visualization. Aerotech’s free HexGen™ sizing software provides the ability to easily simulate the available travel and workspace of the hexapod.

Ordering Information

Feedback (Required)

| Option | Description |

| -E1 | Incremental encoders |

| -E2 | Absolute encoders |

Performance Grade (Optional)

| Option | Description |

| -PL3 | Base performance |

| -PL4 | Ultra high-accuracy performance, ULTRA |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system

Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components

Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |