Automation1 GI4 Laser Scan Head Controller

Now with XY3-100 support! Control two- or three-axis laser scan heads with the Automation GI4 laser scan head controller. The GI4 commands industrial scan heads using the XY2-100 protocol or the new higher resolution XY3-100 protocol and connects inline with an Automation1 controller and drives over HyperWire—enabling powerful performance and simple synchronization with other axes of motion.

The GI4 adds power to your system by unlocking features like our infinite field of view (IFOV), marking on the fly (MOTF) and position synchronized output (PSO) technology alongside the Automation1 platform’s standard laser control functionality.

Description

Specifications

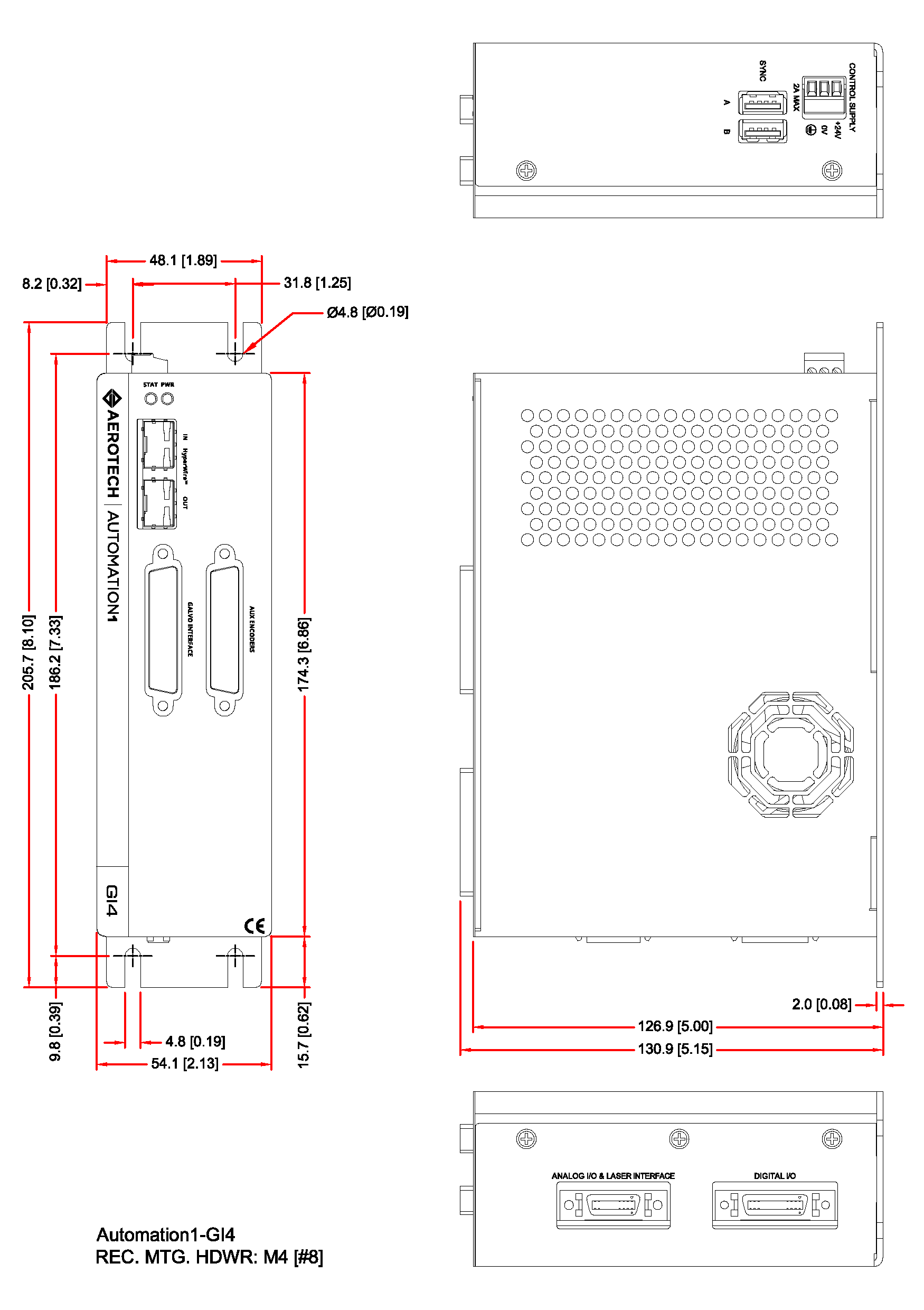

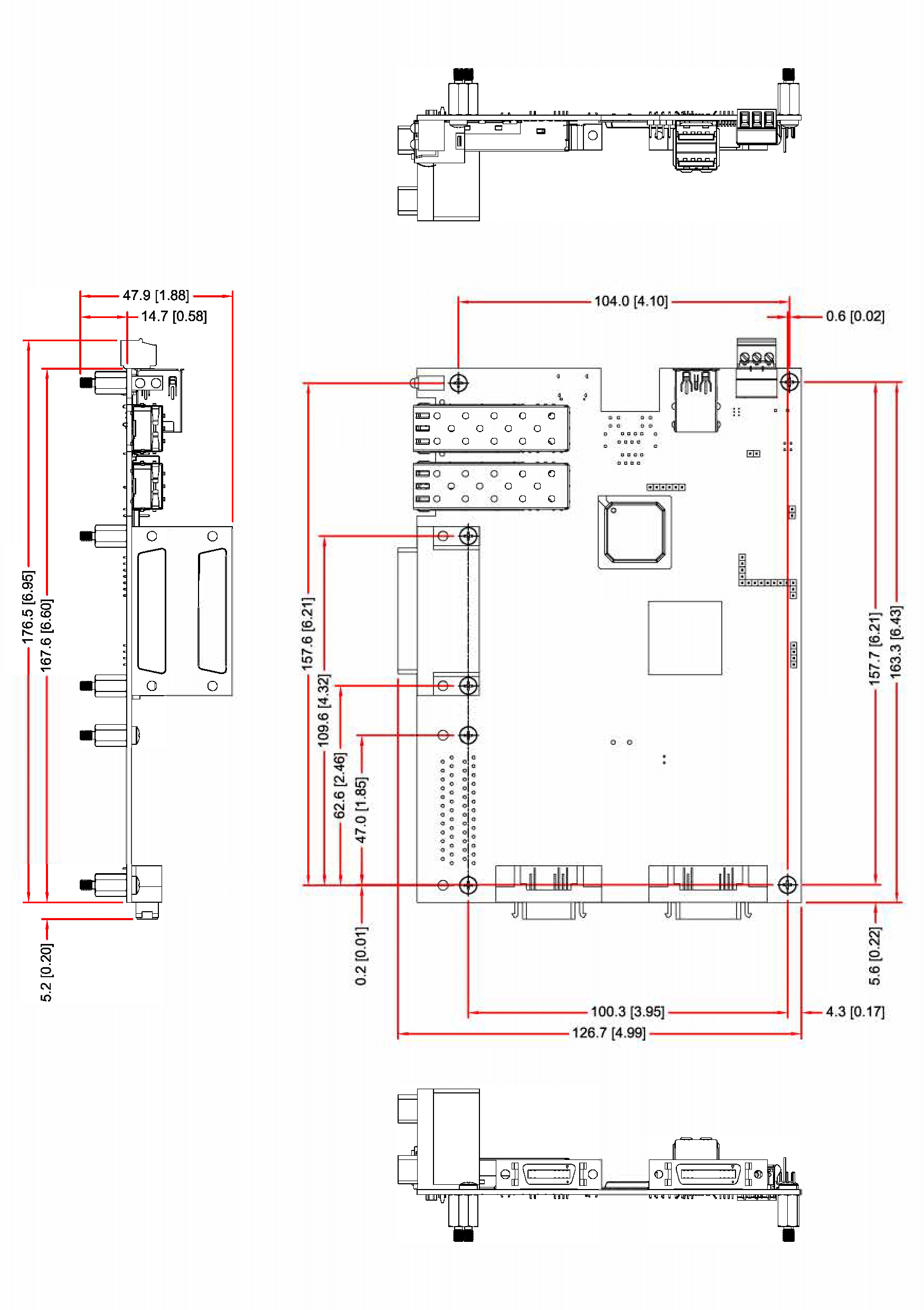

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Laser scan head control for two & three-axis XY2-100 and XY3-100 scanners

- Increases system performance with infinite field of view (IFOV), enabling optimized machine throughput & eliminating stitching errors while maintaining effective pixel resolution

- Minimizes spot distortion by using the central region of your focusing objective (enabled by IFOV)

- Offers marking on the fly for line-follower and other dynamic applications

- Manages laser spot placement with precision using Part-Speed PSO (position synchronized output)

- Features laser control interface with YAG, CO2 & general purpose operating modes

Automation1

The GI4 is a part of the user-friendly Automation1 motion control platform, which includes the following:

The GI4 is an ideal device for machine builders. Not only does it include multiple I/O points, it also connects to the Automation1-iSMC motion control via the HyperWire motion bus side-by-side with other Automation1 drive electronics. The iSMC’s default G-code support couples nicely with the GI4’s standard 3-axis XY2-100 or new higher-resolution XY3-100 support to make all types of laser systems easy to deploy. Even high-end 3D printing processes are implemented as simply as traditional 2D processes such as laser etching, laser engraving, laser cutting, laser welding and laser ablation.

The GI4 includes a data array with more than 67 MB of memory, which enables bitmap and grayscale processes. Simply download laser on/off control arrays or high-resolution grayscale values to the drive array, then call upon these values, synchronized with motion, to control laser firing and power. Use Part-Speed PSO to ensure accurate and consistent pulse-to-pulse spacing while calling on the drive array’s memory to control each laser firing event.

Do all of this while tracking the positions of your servo axes in combination with your galvo scan head axes using IFOV. Simply route your servo axes position feedback from the Automation1 servo drives to the GI4 and the GI4 will combine the galvo and servo positions to accurately control your process. Even if not a hard requirement, using IFOV can help improve throughput and quality by optimizing laser on time and limiting the scan head motion to the central region of the focusing objective.

See Infinite Field of View (IFOV) and Position Synchronized Output (PSO) to learn more.

Two HyperWire connections make it simple to connect the GI4 with other Automation1 drive hardware in a multi-axis configuration. The device is CE approved and EU 2015/863 RoHS 3 directive certified.

Category |

Specification |

| HyperWire Communication | 2x HyperWire small form-factor pluggable (SFP) ports |

| Control Output | Supports two- or three-axis XY2-100 galvo laser scan heads |

| Control Supply Voltage | 24 VDC |

| User Power Supply Output | 5 VDC |

| Modes of Operation | 2 axes, XY2-100 or XY3-100 3 axes, XY2-100 or XY3-100 |

| Protective Features | Output short circuit Control power supply undervoltage |

| Position Synchronized Output (PSO) | Standard: None. Optional: Two-axis Part-Speed PSO Three-axis Part-Speed PSO |

| 25-Pin Axis Connector | Channel 1, 2, and 3 scan head interfaces |

| 25-Pin Aux Encoder Inputs | 2x 40 million counts per second square-wave inputs |

| Digital I/O Connector | 8x optically isolated digital inputs (externally powered, 5-24 VDC) 8x optically isolated digital outputs (externally powered, 5-24 VDC) 1x optically isolated high-speed inputs 1x 5 VDC power supply |

| Analog I/O and Laser Interface Connector | Laser Outputs 1,2, and 3 (work with controller Galvo Functions) 1x PSO output 1x PSO external sync input 2x 16-bit single-ended ±10 V analog output 4x 16-bit differential ±10 V analog inputs |

| Sync Ports | 2x a bi-directional high-speed proprietary interface ports for transmitting encoder signals between drives, used for infinite field of view (IFOV) applications. |

| Drive Array Memory | 67.1 MB (16,777,216 32-bit elements) |

| High Speed Data Capture | Yes (50 ns latency) |

| Automatic Brake Control | Assignable digital output |

| E-Stop Sense Input | Assignable digital input |

| Position Command Update Rate | 100 kHz |

| Operating Temperature | 0 to 40 °C |

| Storage Temperature | -30 to 85 °C |

| Weight | 0.59 kg (1.30 lb) |

| Compliance | CE approved, Follows EU 2015/863 RoHS 3 directive |

Ordering Information

Automation1 GI4

| Option | Description |

| Automation1 GI4 | Automation1 GI4 Laser Scan Head Controller |

Packaging

| Option | Description |

| -P1 | Standard Packaging |

| -P2 | OEM Packaging |

PSO

| Option | Description |

| -PSO0 | No PSO firing (default) |

| -PSO5 | Two-axis Part-Speed PSO |

| -PSO6 | Three-axis Part-Speed PSO |