Automation1 iXC4 PWM Servo Drive with Motion Controller

The Automation1 iXC4 PWM servo motor drive with integrated motion controller is two solutions in one: it’s capable of complete machine control and provides sub-nanometer levels of servo motor control. The powerful Automation1-iSMC motion controller is loaded directly onto the same hardware that runs the drive, which in turn manages the trajectory of up to 12 axes of control over the HyperWire motion bus.

The iXC4 is the powerful center of your motion control architecture. It has a full motion controller, connects to other Automation1 drives over HyperWire and connects to other automation devices over EtherCAT, Modbus TCP/IP or a TCP Socket interface. Multi-axis Part-Speed PSO enables precision control of your industrial laser or process tool synchronized with your motion trajectory.

Description

Specifications

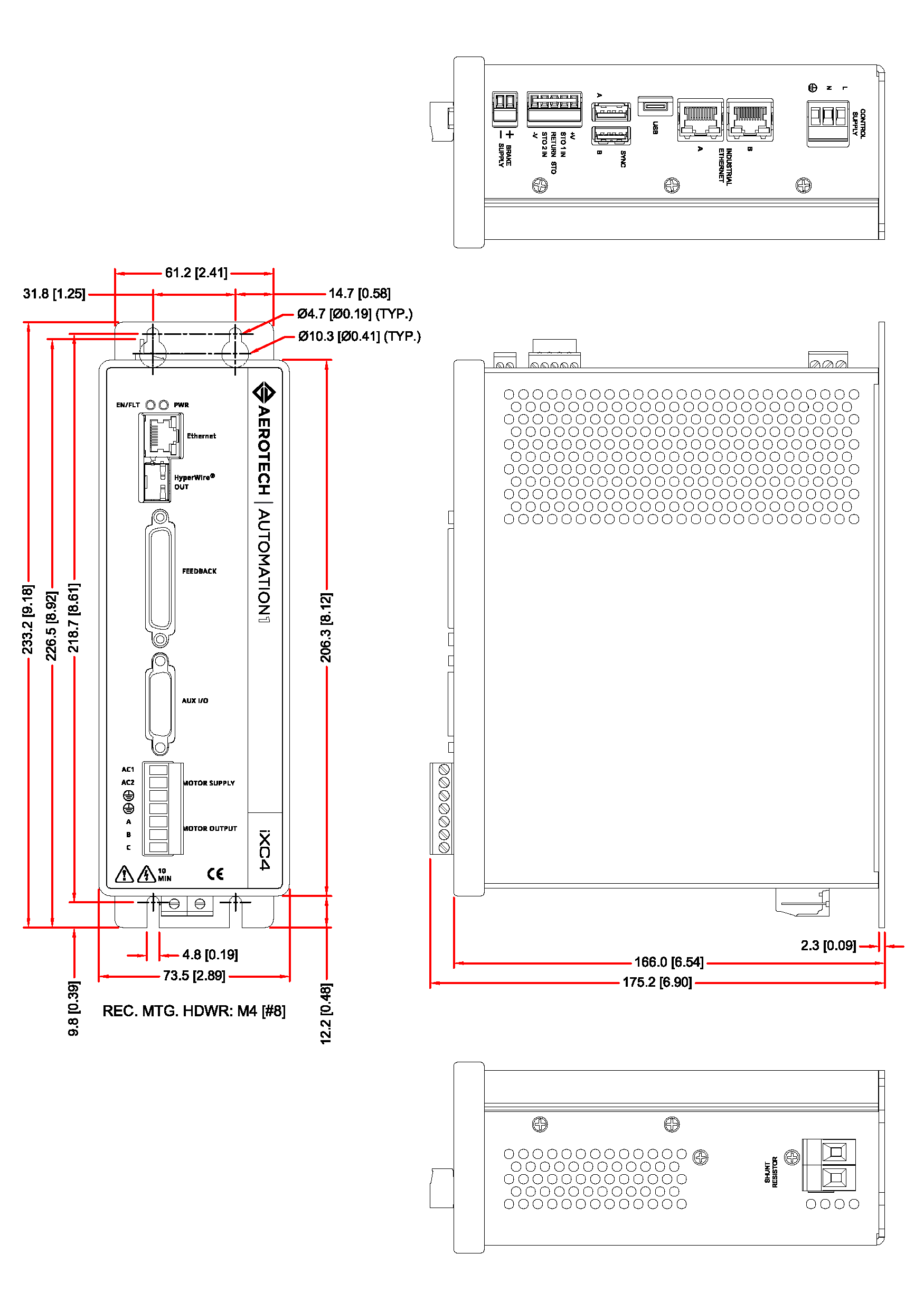

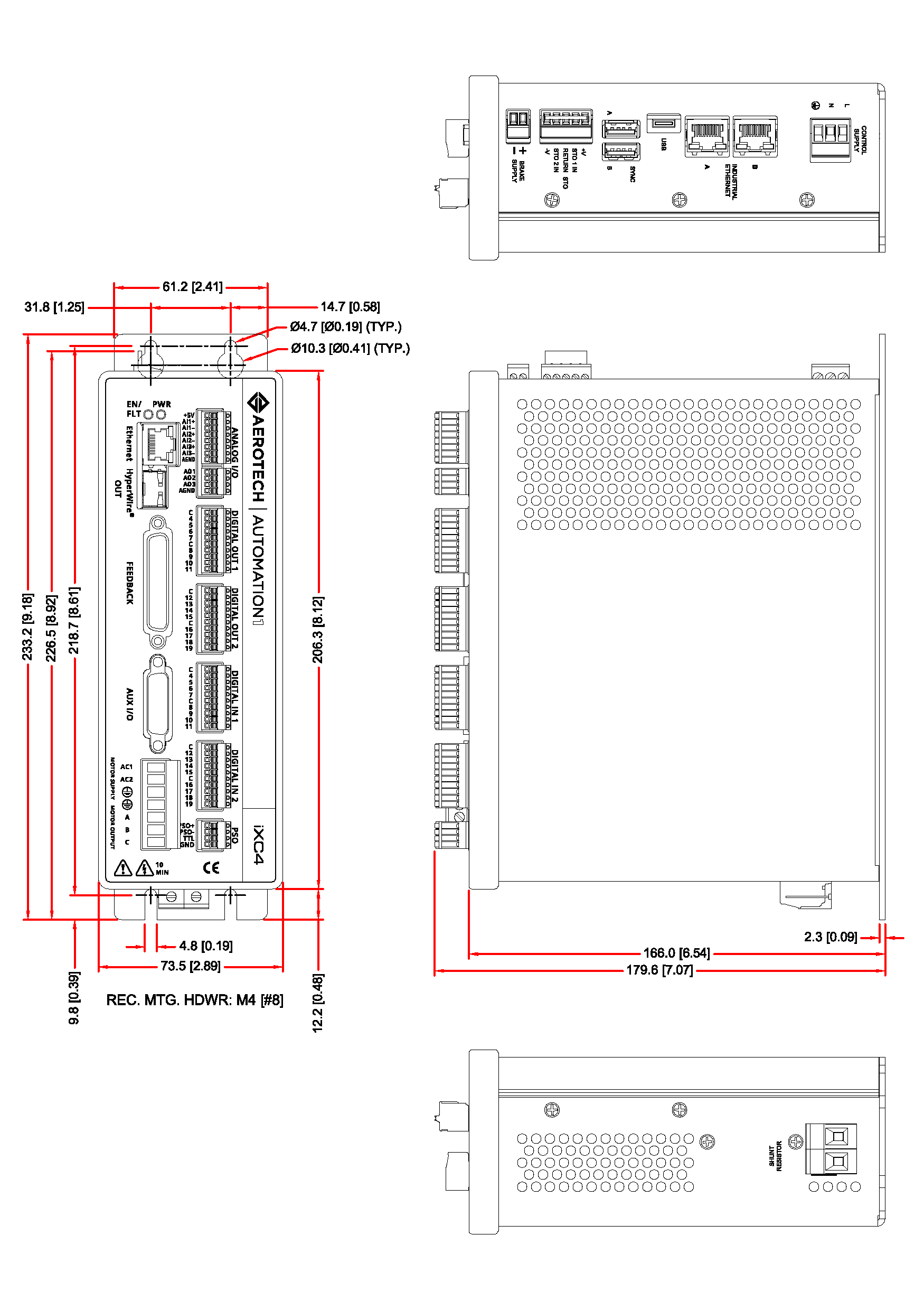

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Unlock the full motion control power of our Automation1-iSMC intelligent software-based motion controller

- Features complete configuration & performance capability of XC4 servo motor drive

- Connect to the controller using EtherCAT, Modbus or a Socket interface

- Enjoy up to 12 axes of control by connecting more Automation1 drives over the HyperWire fiber-optic bus

- Expand your I/O by adding expansion board to the iXC4 or to other connected drives

- Available with Multi-axis Position Synchronized Output (PSO) (Single-axis is standard)

Motion. Control. Together.

The Automation1-iXC4, a hardware platform for running the Automation1-iSMC intelligent software-based motion controller, features a servo motor drive. That means it has the ability to run your entire machine’s control, act as a servo drive for a single axis and control up to 11 added axes of motion over our fiber-optic HyperWire motion bus. The supported EtherCAT, Modbus TCP and Socket interface enable true full machine and motion system control. Combining this technology on a single hardware device lowers your machine costs, reduces machine size and increases reliability.

The iSMC, which runs on the iXC4, is programmable in AeroScript from the Automation1 Studio application and several available APIs.

Automation1

The iXC4 is a part of the user-friendly Automation1 motion control platform, which includes the following:

The iXC4 PWM servo drive with motion controller is the right choice for your precision machine or system. It begins with superior motion control technology. The Automation1-iSMC (configured separately and installed on the iXC4) contains technology once reserved for high-end PC-based architectures.

That’s not the only reason the iXC4 is a game-changer. It also contains our XC4 single-axis PWM digital drive -- within the same compact package. You can also add up to 11 additional axes of control over the HyperWire® fiber-optic motion bus.

The iSMC controller can connect to, command and control any other Automation1 servo motor drive. The iXC4 and additional servo motor drives can be configured with I/O expansion boards, giving the iSMC controller the connectivity required to take full control of your machine or system.

The iXC4 PWM amplifiers control brushless DC, brush DC, voice coil or stepper motor types at up to 340 VDC operating voltage and 30 A peak current capability. The current loop and servo loop are closed digitally at 20 kHz, assuring the highest level of positioning accuracy and repeatability. Digital and analog data collection and position capturing occur at the same 20 kHz rates. Axis and process data is quickly communicated to the motion controller for processing in real time.

Standard drive features for the iXC4 include safe torque off (STO), a data array consisting of over 4 million 32-bit elements (16.7 MB), digital and analog I/O (see table), one-axis Position Synchronized Output (PSO), dedicated home and end-of-travel limit inputs, and an enhanced current sense device. Encoder support includes squarewave, sine-wave and absolute encoders.

The standard iXC4 accepts square-wave encoder feedback at rates of up to 40 million counts-per-second. Sine-wave encoders can be multiplied by up to 16,384 -- producing high resolution position feedback -- with the optional encoder multiplier feature. Each single-axis iXC4 can be configured with the MX1 encoder multiplier, enabling higher levels of position and velocity control.

Each drive-based controller has an optional I/O expansion board, significantly increasing the number of I/O points. This I/O board includes a dedicated PSO output and a PSO synchronization input, which are often used to synchronize process control with an external mode locked frequency. Upgrade the drive’s PSO capabilities by adding Three-axis Part-Speed PSO.

Platform Power

More than just hardware, the iXC4 gives you access to the complete power of the Automation1 motion control platform. This includes the Automation1 motion development kit (MDK), the intelligent software-based controller (iSMC) and the powerful AeroScript™ programming language with integrated RS-274 G and M code support. The Automation1 iSMC can also be programmed by various controller APIs, providing flexible methods of integrating the iXC4 and the machine and axes it controls into your system architecture.

Specification |

Description |

| Motion Controller(1) | Aerotech’s Automation1 iSMC Intelligent Software-Based Motion Controller (version 2.00 and above) |

| Motor Style | Brush, brushless, voice coil, stepper(2) |

| Motor Supply | Single-phase 0-240 VAC; 50/60 Hz |

| Control Supply | 100-240 VAC; 50/60 Hz |

| Bus Voltage(3) | 0-340 VDC |

| Peak Output Current (1 sec)(4) | 10 Apk | 20 Apk | 30 Apk |

| Continuous Output Current(4)(5) | 5 Apk | 10 Apk | 10 Apk |

| Position Synchronized Output (PSO) | Standard: One-axis PSO (includes one-axis part-speed PSO)(6) Optional: Three-axis part-speed PSO |

| 25-Pin Motor Feedback Connector | High-speed differential inputs (encoder sin, cos and marker) CW and CCW limits Hall effect sensor inputs (A, B and C) Analog motor temperature input (accepts digital) Brake output |

| 26-Pin Auxiliary Feedback Connector | High-speed differential inputs (encoder sin, cos and marker)* 4x optically isolated digital inputs 4x optically isolated digital outputs 1x 16-bit differential ±10 V analog input 1x 16-bit single-ended ±10 V analog output 2x optically isolated high-speed inputs *This channel is bidirectional and can be used to echo out encoder signal |

| Multiplier Options | MX0 Option: Primary Encoder: 40 million counts-per-second square-wave input Auxiliary Encoder: 40 million counts-per-second square-wave input MX1 Option: Primary Encoder: 2 MHz / 450 kHz (bandwidth selectable) sine-wave input, encoder multiplier up to x16,384* Auxiliary Encoder: 40 million counts per second square-wave input *Encoders multiplied with this input cannot be echoed out. |

| I/O Expansion Board (-EB1) | 1x additional PSO connection point 1x PSO synchronization input 16x digital inputs, optically isolated 16x digital outputs, optically isolated 3x analog inputs, 16-bit, differential, ±10 V 3x analog outputs, 16-bit, single-ended, ±10 V |

| Drive Array Memory | 4,194,304 32-bit elements (16.7 MB) |

| High-Speed Data Capture | Yes (50 ns latency) |

| Safe Torque Off (STO) | Yes, SIL3/PLe/Cat 4 |

| HyperWire Connections | 1x HyperWire small form-factor pluggable (SFP) ports |

| Automatic Brake Control | Standard; 24 V at 1 A |

| Absolute Encoder | Renishaw resolute BiSS; EnDat 2.1; and EnDat 2.2 |

| Current Loop Update Rate | 20 kHz |

| Servo Loop Update Rate | 20 kHz |

| Power Amplifier Bandwidth | Selectable through software (85-95% efficiency) |

| Minimum Load Inductance | 0.1 mH |

| Operating Temperature | 0 to 40°C0 to 40°C |

| Storage Temperature | -30 to 85°C |

| Weight | 2.36 kg (5.20 lb) |

| Compliance | CE approved, NRTL safety certification, EU 2015/863 RoHS 3 directive |

Ordering Information

Controller Configuration

| Description |

| To configure and load the motion controller on the iXC4 drive, please use configure and order an Automation1-iSMC intelligent controller with your iXC4 drive. The Automation1-iSMC configuration should include the iXC4 as the “hardware platform.” |

Automation1 iXC4

| Option | Description |

| Automation1 iXC4 | PWM Servo Drive with Motion Controller |

Peak Current

| Option | Description |

| -10 | 10 A peak, 5 A cont. current (default) |

| -20 | 20 peak, 10 A cont. current |

| -30 | 30 A peak, 10 A cont. current |

Expansion Board

| Option | Description |

| -EB0 | No expansion board |

| -EB1 | IO expansion board |

Multiplier

| Option | Description |

| -MX0 | No encoder board (default) |

| -MX1 | 2 MHz / 450 kHz (bandwidth selectable) x16384 multiplier (primary), no multiplier (auxiliary) |

PSO

| Option | Description |

| -PSO1(1) | One-axis PSO (includes One-axis Part-Speed PSO) (Default) |

| -PSO6 | Three-axis Part-Speed PSO |

- 1. Encoder feedback-based PSO requires the -MX0 multiplier option.

External Shunt

| Option | Description |

| -SX0 | No 2-pin connector for external shunt (default) |

| -SX1 | 2-pin connector for external shunt |