Products

Built for durability and rooted in 50 years of expertise, our motion and positioning products are known worldwide for delivering superior precision, accuracy, consistency and throughput. Standard or custom, component or system – we have precisely what you need.

-

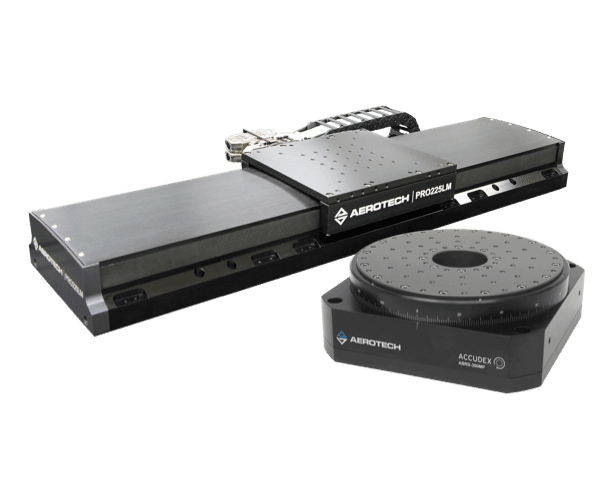

Stages & Actuators

Linear, Rotary, Lift & XY

-

Motion Control Platforms

Software, Controllers, Drives & Drive Racks

-

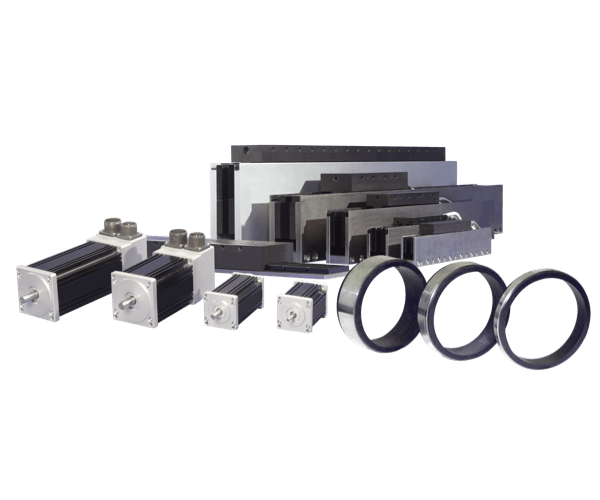

Motors

U-Channel, Flat, Rotary, Brushed & Brushless

-

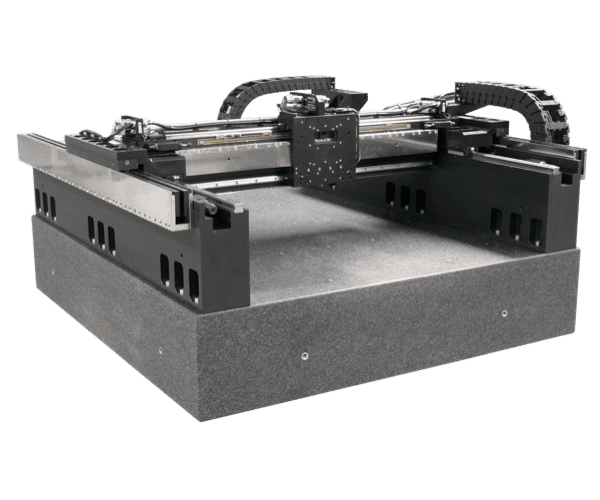

Gantries

Mechanical- or Air-Bearing, Large & Small

-

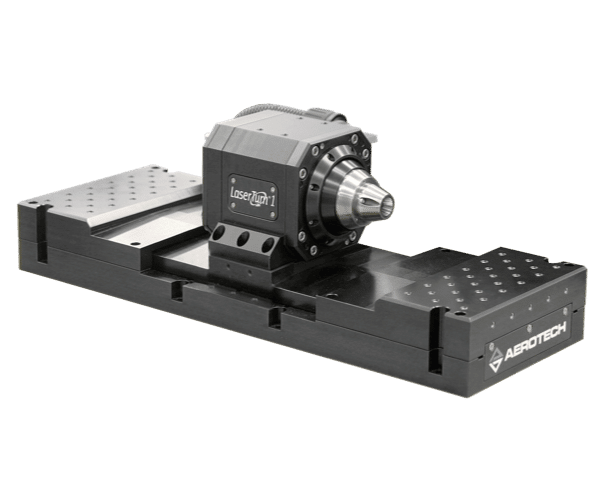

Laser Scan Heads

2D, 3D, 5D & Custom

-

Gimbals & Optical Mounts

Direct-Drive or Gear-Driven

-

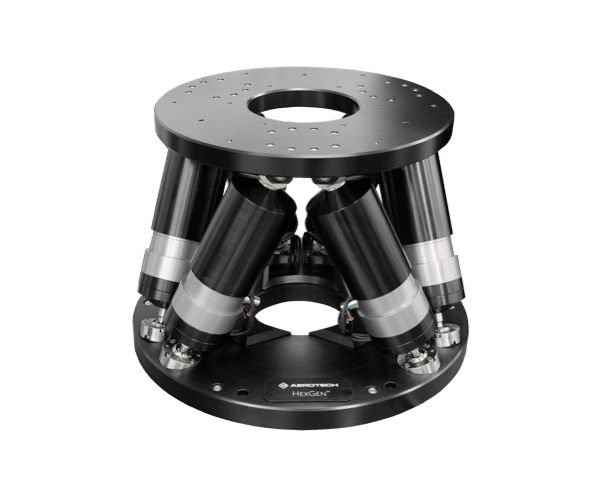

Hexapods

Ultra-Precise, Both Small & Large

-

Process-Specific Products

Medical, Photonics & Laser Processing

-

Custom Engineered Motion Systems

Customized Products, Complete Motion Subsystems

-

Integrated Automation Systems

Custom Automation Systems Built for Your Process