Webinar

Dynamic Error Reduction via Galvo Compensation

About the Webinar

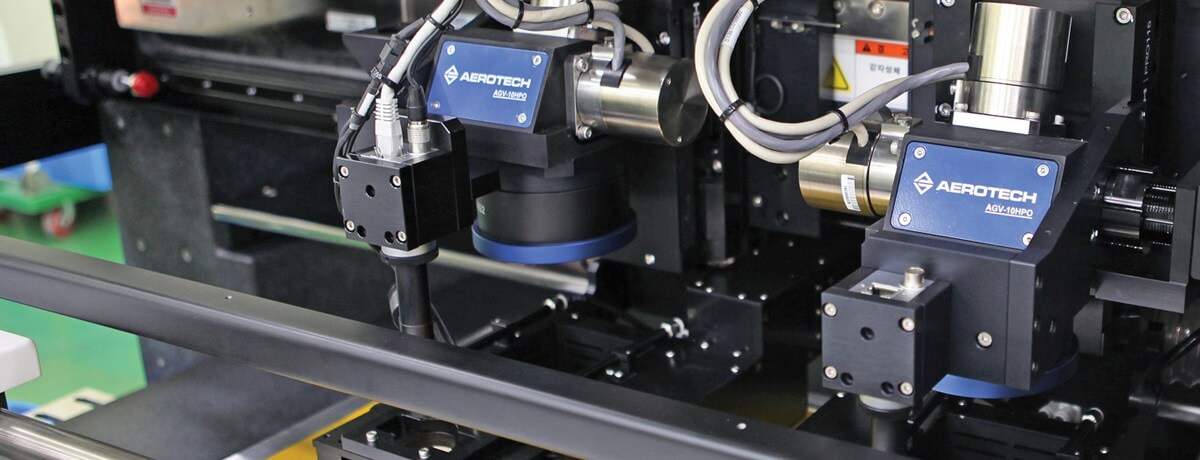

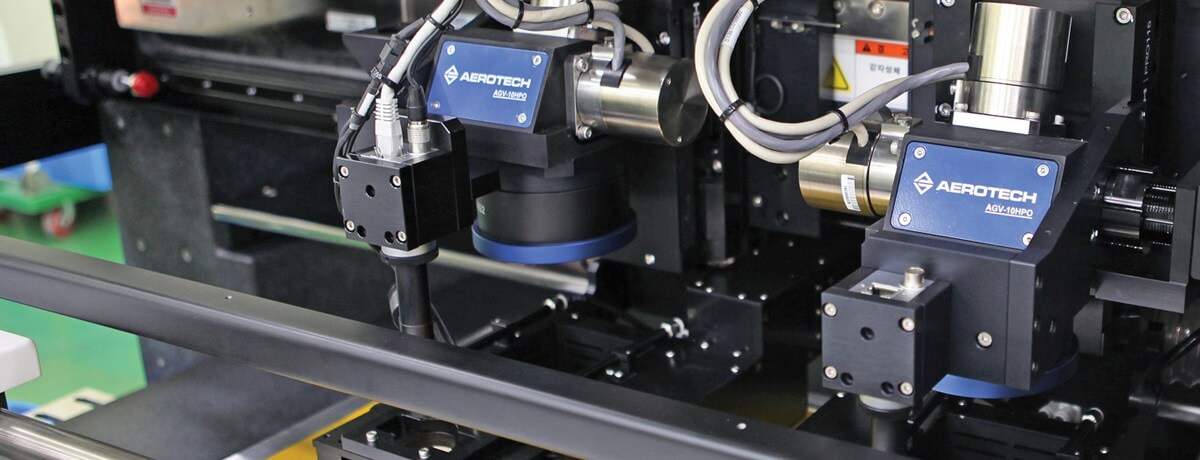

A common misconception is that high throughput implies higher speeds, but the real factor that impacts throughput is higher accelerations. This webinar will cover 1) problems that arise in fixed-beam positioning (i.e., moving load) where the large moving mass of a system becomes a difficult problem to solve and 2) how these challenges may be overcome with hybrid stage-scanner system architectures.

Learning Objectives

This webinar will provide insight into most dominant performance limitations in modern dynamic laser machining applications. You will also learn the advantages of using a galvo — including increased performance rates — made possible through the reduction of moving mass and increased frequency response. The presenter will offer an analysis of present error reductions and overall/systemic errors in these hybrid systems.

Who Should Attend

- Automation equipment engineers responsible for developing custom in-house tools for applications where off-the-shelf equipment isn’t adequate

- Anyone responsible for sourcing outside OEM equipment or who works with custom machine providers for laser processing

Scott Schmidt is an applications engineering manager at Aerotech Inc., where he has gained 17 years of experience with advanced laser processing and micromachining. He holds a bachelor's degree in electrical engineering from Penn State University and a master’s degree in electrical and computer engineering from the University of Massachusetts. Contact Scott at sschmidt@aerotech.com or +1.412.599.6483.