HermeSys Laser Seam Welding System

The HermeSys® is the first motion subsystem to address the most complex requirements laser seam-welding applications. The compact, rigid platform increases weld quality while reducing part processing time.

Description

Specifications

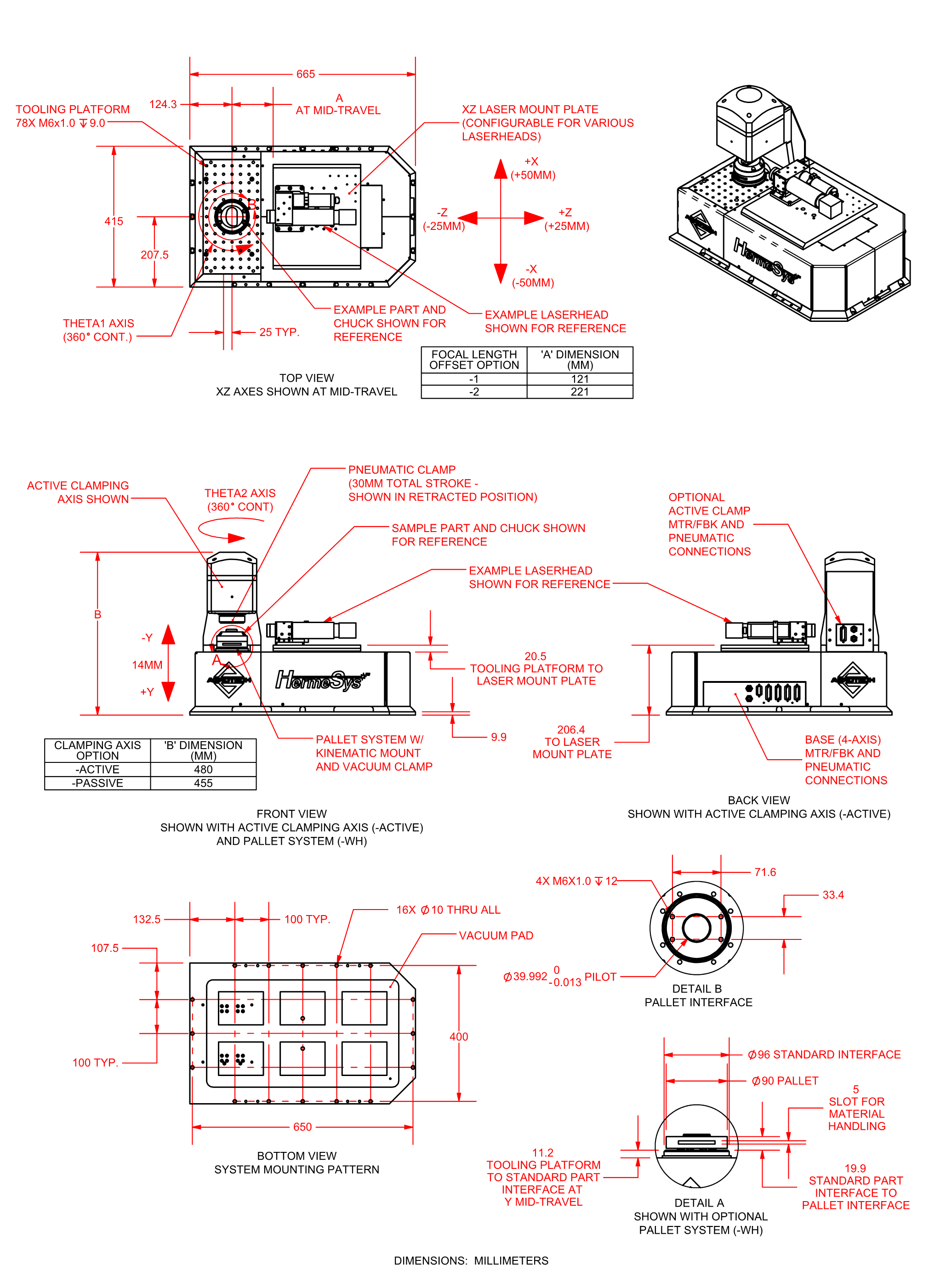

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Optimized motion subsystem for laser seam welding

- Standard 4-axis configuration supports 3D weld profiles

- Optional active drive or passive part clamping assembly

Direct-Drive Technology

Weld contours on implantable devices often have small features that result in large accelerations during the weld process. The direct-drive technology used on the linear and rotary axes of the HermeSys minimizes tracking errors through these complex contours. Directly coupled feedback devices are also used to ensure accurate placement of the part during the weld process.

Flexible Welding Platform

Devices intended for deployment in the body have strict limitations on the allowable package size. With travels that support package sizes up to 100 x 100 mm the HermeSys has the capacity to handle a wide array of package configurations.

3D Weld Profiles

Many weld profiles require motion in three dimensions to traverse around penetrations in the case. The HermeSys comes equipped with a 14 mm travel vertical axis that allows for non-planar weld profiles to be easily implemented.

Optional Clamp Assembly

The weld process can induce stress on the package due to localized heating of the case. This stress can result in separation of the case halves causing the weld seam to fail. The HermeSys has an optional passive or active driven pneumatic clamp assembly to ensure consistent contact between the case halves during the welding process. This clamp assembly can be calibrated to give accurate and repeatable clamping force.

Real-time Transformation

Aerotech's Automation 3200 control platform includes specialized real-time transformation capability that greatly simplifies path programming. Weld profiles are programmed directly in part coordinate space and transformed in real time to the HermeSys actuator coordinate space. This allows for on-machine modification of the program to optimize the weld profile. Advanced 2D and 3D path optimization tools can be applied to automatically adjust weld speed and laser power to ensure consistent weld quality over a wide range of part features.

Kinematic Part Fixture

An automated load/unload system is recommended to fully utilize the throughput enhancements that are available with the HermeSys system. Aerotech has designed a kinematic coupling system for precision registration of the devices on the rotary axis. The coupling system has wide acceptance angles on the mating interfaces that allow for low cost robotic or pneumatic material handling systems.

Ordering Information

HermeSys Four-Axis Hermetic Seam-Welding Platform

| Option | Description |

Focal Length (Required)

| Option | Description |

| -FL1 | Linear stage position set up for < 200 mm focal length |

| -FL2 | Linear stage position set up for >200 mm focal length |

Pneumatic Clamp Assembly (Optional)

| Option | Description |

| -CA1 | Passive pneumatic clamp assembly |

| -CA2 | Active pneumatic clamp assembly, equipped with motor and position feedback device |

Material Handling (Optional)

| Option | Description |

| -1 | Linear stage position setup for <200 mm focal length |

| -2 | Linear stage position setup for >200 mm focal length |

Material Handling (Optional)

| Option | Description |

| -MH1 | Pallet system with kinematic mount |

Integration (Required)

erotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system

Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components

Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |