ALAR-LP Large Aperture Rotary Stages

The ALAR family of direct-drive, large-aperture rotary stages provides superior angular positioning and velocity control. ALAR-LP (low profile) offers a generous payload capacity with a short overall height, making it ideal for space-constrained applications. Featuring a large-diameter clear aperture and a non-cogging direct-drive motor, ALAR-LP stages offer a better-performing alternative to worm-gear stages.

Description

Specifications

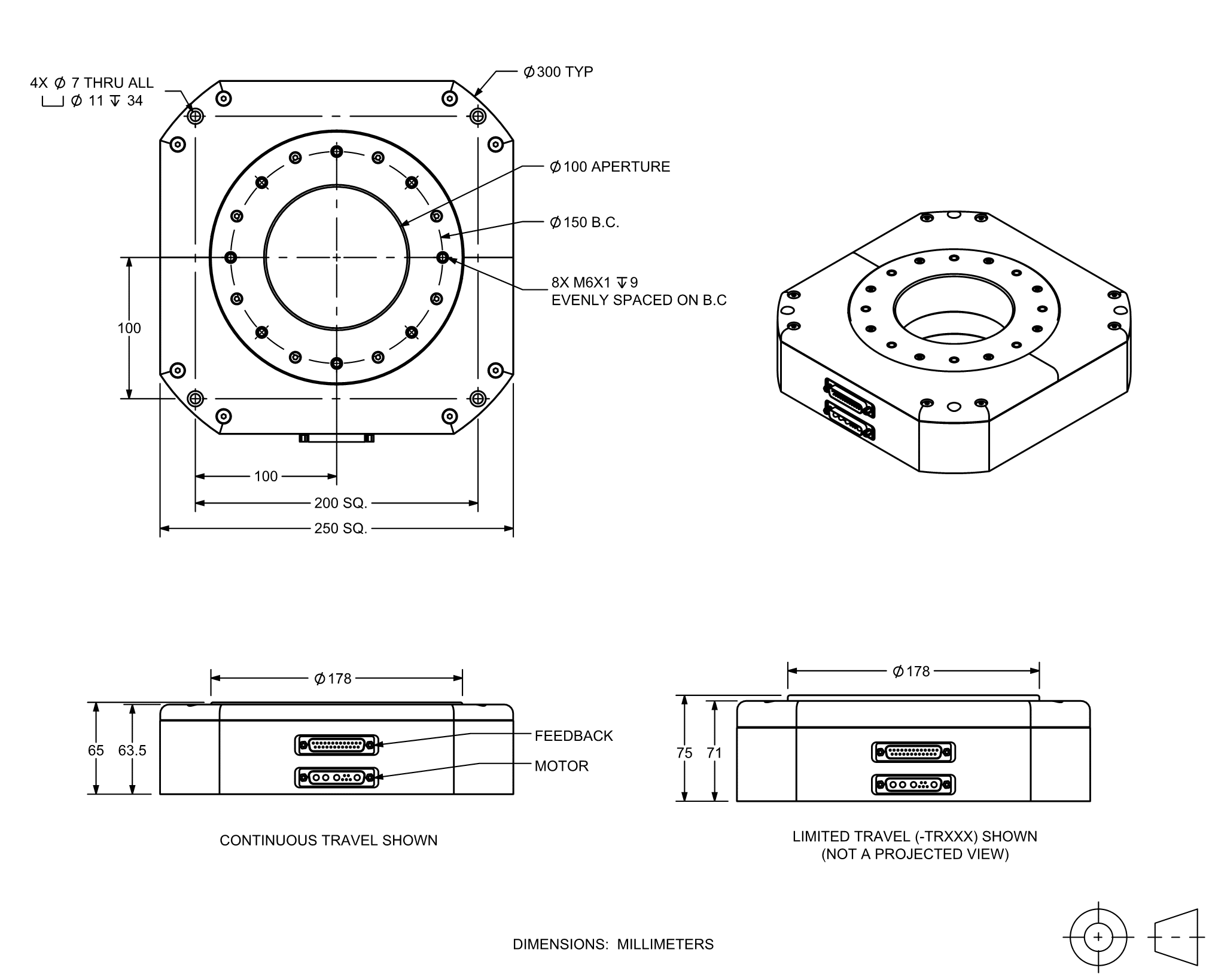

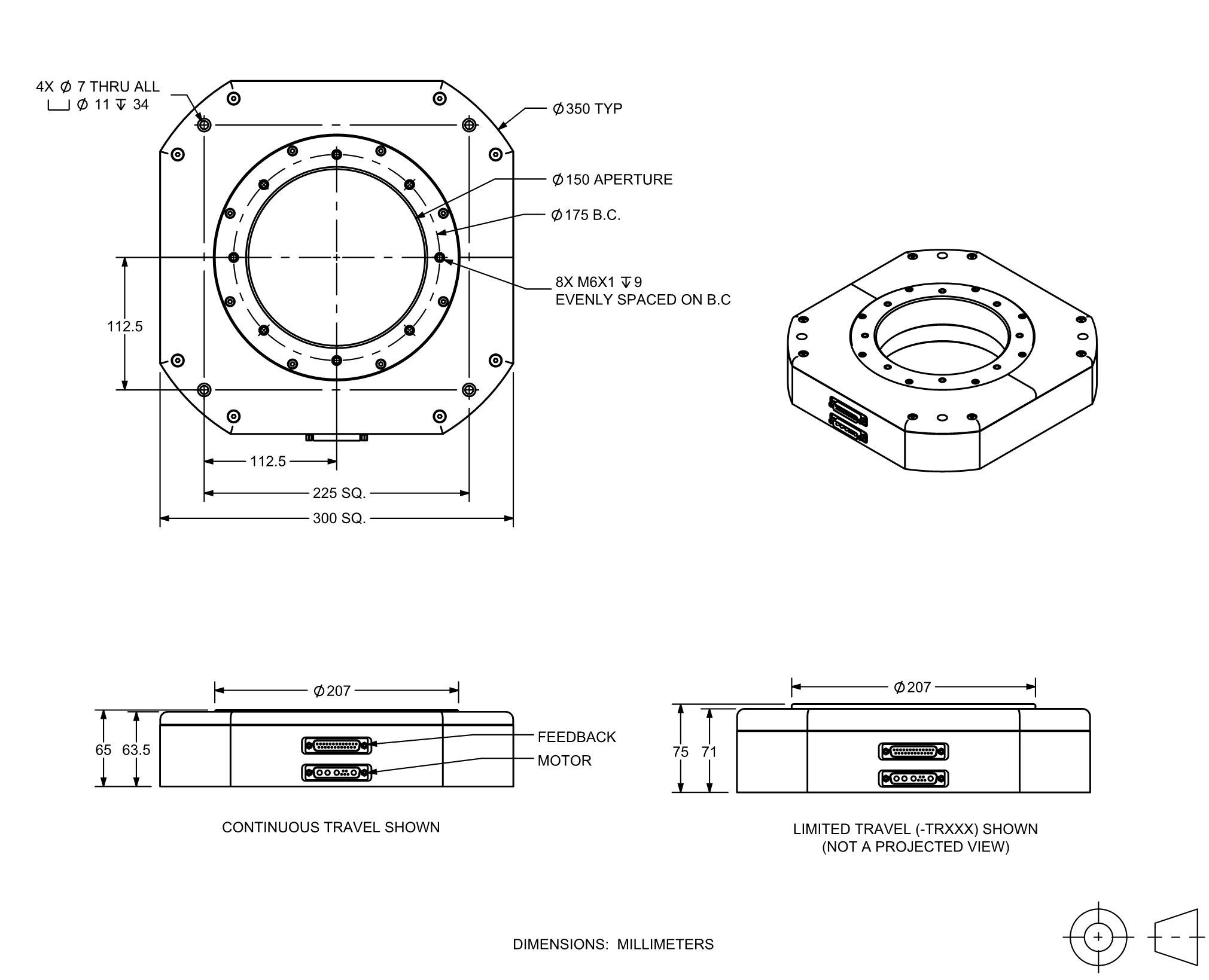

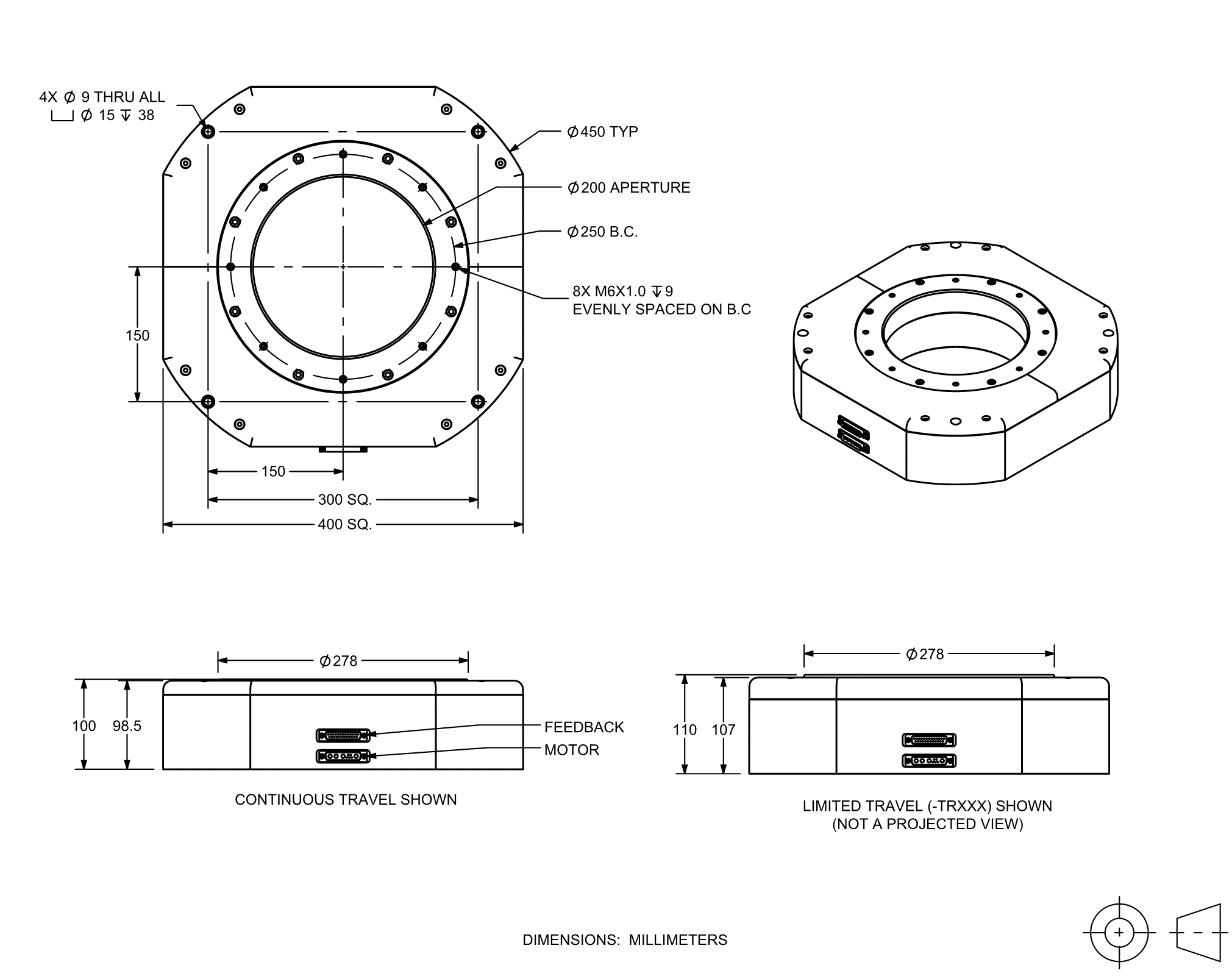

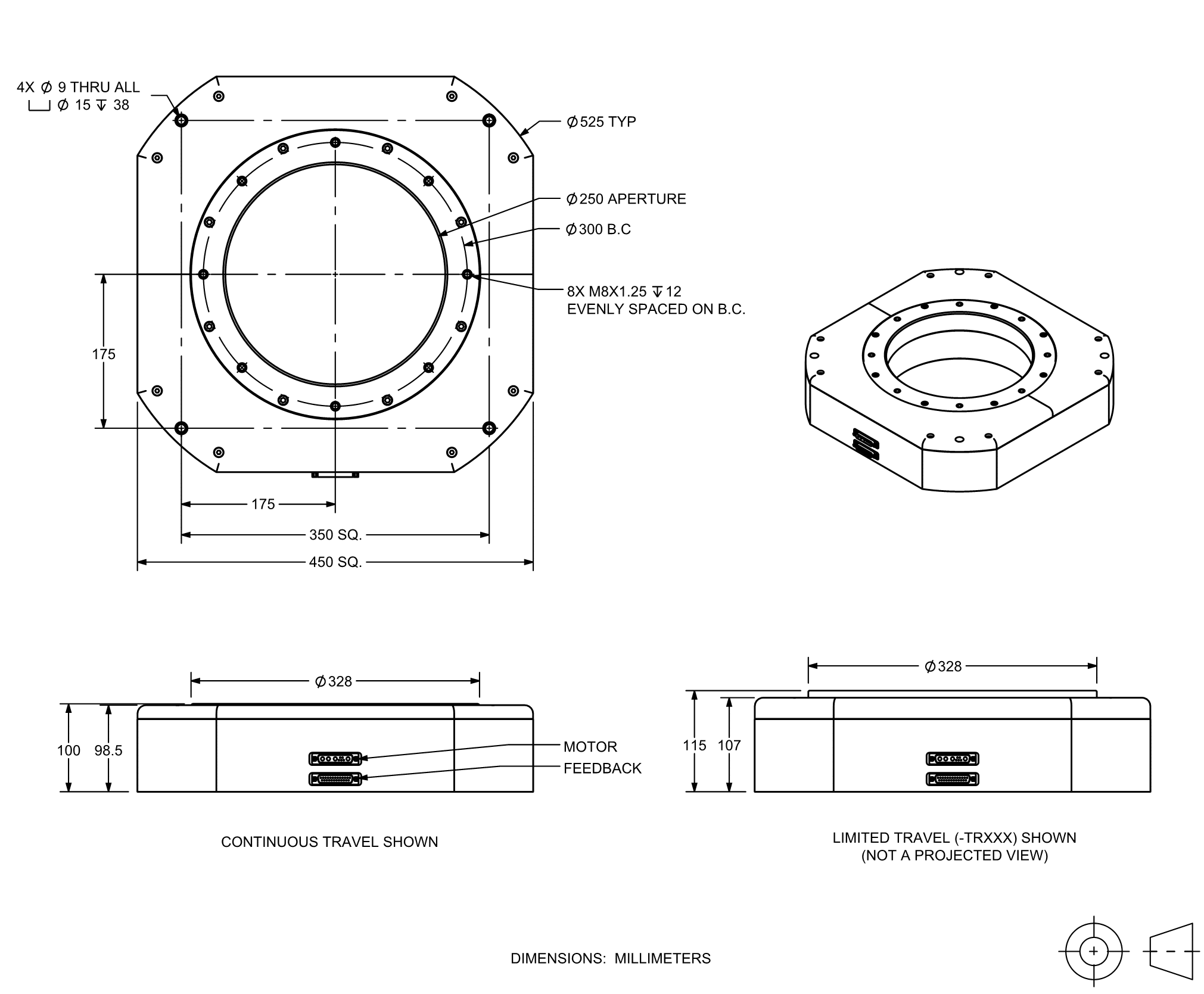

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

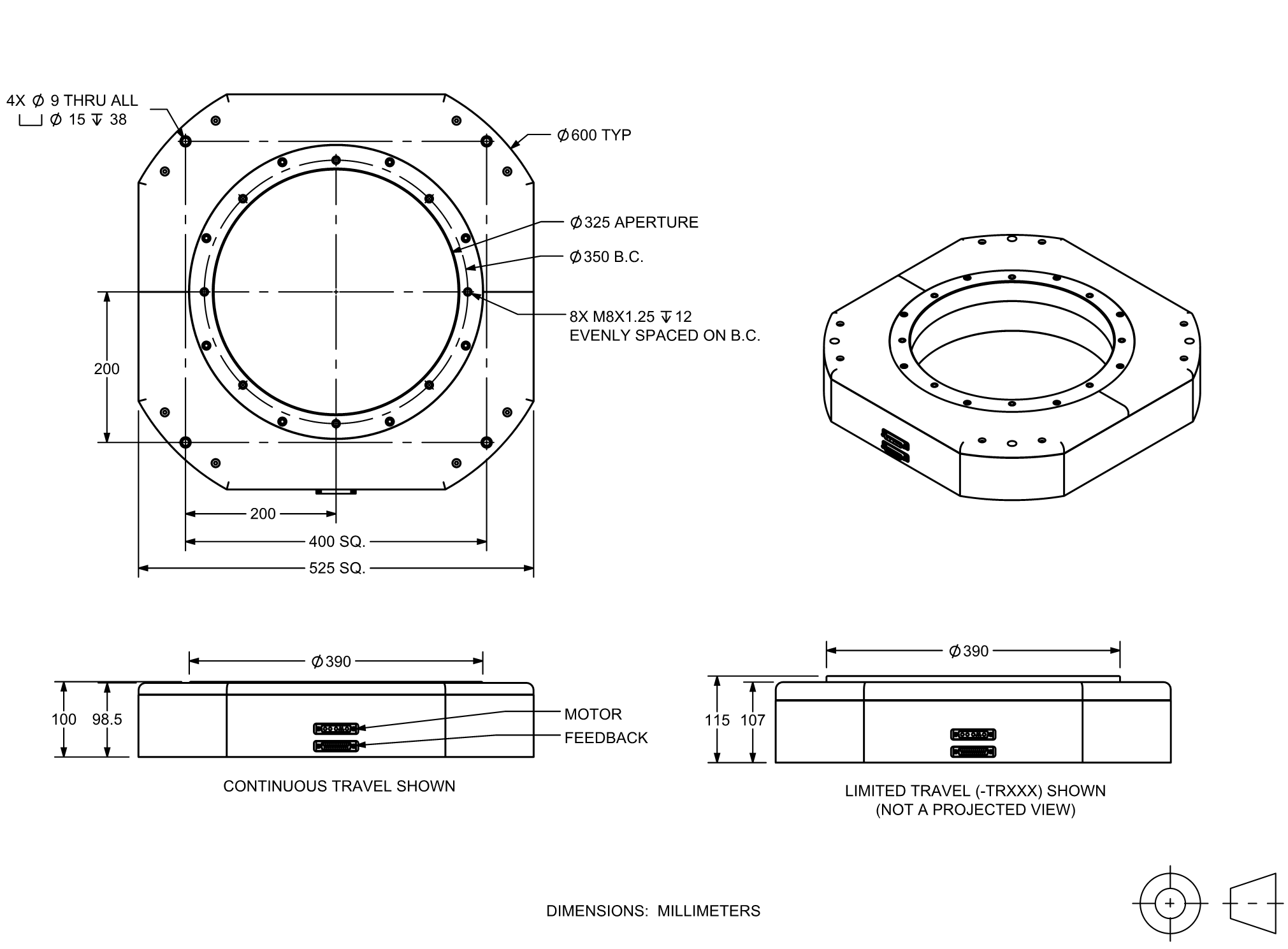

Dimensions

Ordering Info

Downloads

Description

Design Features

- Offers a low-profile form factor with overall stage height as short as 65 mm for space-constrained applications

- Integrates easily into systems & machines thanks to large-diameter clear aperture up to 325 mm

- Delivers extremely precise, smooth, cog-free rotation with direct-drive torque motor

- Supports large axial & radial loads, ideal for linear/rotary stage combinations & gimbal configurations

- Provides long service life & consistent performance over time

- Available with absolute encoder option & limited travel for maximum payload security

Key Applications

ALAR-LP stages are best suited for applications including:

- Single- and multi-axis sensor testing

- Inertial navigation device qualification

- Missile seeker testing

- Antenna testing

- Photonic component alignment

- High-accuracy laser processing

- Precision wafer inspection

- Custom gimbal assemblies

Advantage: ALAR

ALAR-LP offers numerous advantages over worm-drive stages. Because ALAR stages use direct-drive torque motors, they are free from backlash, vibration, and excessive wear commonly associated with gear-driven stages, and they are also capable of much higher speeds and accelerations. These advantages translate to higher system accuracy, repeatability, and longevity, as well as greater throughput. Users can more precisely manufacture, inspect, or process more parts in less time, leading to lower operating costs and higher profits.

Brushless, Slotless Direct-Drive Motors

Aerotech’s brushless, direct-drive motors are featured in all ALAR stages. Because there are neither brushes to wear, nor gear trains or couplings to maintain, ALAR stages are capable of high speeds and accelerations, plus consistent, stable performance over time with zero backlash, windup, or hysteresis. Further, ALAR motors are both slotless and ironless, thereby eliminating cogging and torque ripple to deliver exceptionally smooth motion. ALAR stages are ideal for applications requiring outstanding contoured motion, smooth scan velocities, and precise incremental steps.

Generous Payload Capacity with a Low Profile

Large-diameter angular contact bearings provide high axial- and radial-load capacities, maximizing positioning performance with respect to axis error motions, stiffness, and rotating friction. ALAR-LP is up to 40% shorter and up to 50% lighter than ALAR-SP, making this low-profile stage attractive in space- and weight constrained applications. ALAR-LP performs best when oriented with a vertical axis of rotation.

Flexible Configurations for Simplified Integration

ALAR-LP is offered with features and options that facilitate easy integration into multi-axis motion systems and subsystems. It is available with a range of clear aperture diameters from 100 mm to 325 mm, and also a variety of feedback options including analog 1 Vpp, digital RS422, and absolute encoders. Continuous 360-degree travel is standard, with available limited-travel options ranging from 10 degrees to 340 degrees. ALAR-LP stages can even be adapted for use in vacuum environments.

Applications

Common applications for ALAR-LP stages include single- and multi-axis sensor testing, missile seeker testing, antenna testing, inertial navigation device testing, photonic component alignment, high-accuracy laser machining, and precision wafer inspection. Due to their shorter height and lower mass, ALAR-LP stages are well-suited for linear/rotary stage combinations, and they can also be used as the azimuth axis in gimbal arrangements. The large-diameter clear aperture and direct-drive motor make ALAR a better-performing alternative to more traditional worm-gear stages.

Ordering Information

ALAR-LP Large-Aperature Rotary Stage

| Option | Description |

| ALAR100LP | Mechanical-bearing, direct-drive rotary stage, low profile, 100 mm aperture |

| ALAR150LP | Mechanical-bearing, direct-drive rotary stage, low profile, 150 mm aperture |

| ALAR200LP | Mechanical-bearing, direct-drive rotary stage, low profile, 200 mm aperture |

| ALAR250LP | Mechanical-bearing, direct-drive rotary stage, low profile, 250 mm aperture |

| ALAR325LP | Mechanical-bearing, direct-drive rotary stage, low profile, 325 mm aperture |

Travel (Required)

| Option | Description |

| Continuous travel (standard) | |

| -TR010 | Limited travel, ±5 degrees |

| -TR020 | Limited travel, ±10 degrees |

| -TR030 | Limited travel, ±15 degrees |

| -TR060 | Limited travel, ±30 degrees |

| -TR090 | Limited travel, ±45 degrees |

| -TR120 | Limited travel, ±60 degrees |

| -TR180 | Limited travel, ±90 degrees |

| -TR240 | Limited travel, ±120 degrees |

| -TR300 | Limited travel, ±150 degrees |

| -TR340 | Limited travel, ±170 degrees |

Feedback (Required)

| Option | Description |

| -E1 | Incremental encoder, 1 Vpp |

| -E2 | Incremental encoder, digital RS422, x4 interpolation |

| -E3 | Incremental encoder, digital RS422, x20 interpolation |

| -E4 | Incremental encoder, digital RS422, x40 interpolation |

| -E5 | Incremental encoder, digital RS422, x100 interpolation |

| -E6 | Incremental encoder, digital RS422, x200 interpolation |

| -E7 | Absolute encoder |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |