PRO225SL Mechanical Bearing, Ball-Screw Stage

The PRO225SL provides an optimal balance of positioning performance, payload capacity and size. Compared to the narrower PRO190SL, PRO225SL can carry considerably higher payloads due to its larger bearings and motor. Combining superior craftsmanship with the highest quality components, PRO225SL stages consistently and reliably deliver best-in-class positioning performance. Thoughtfully engineered features and options, coupled with competitive pricing, make PRO225SL stages the ideal choice for streamlined integration into a wide variety of precision systems, machines and processes.

Description

Specifications

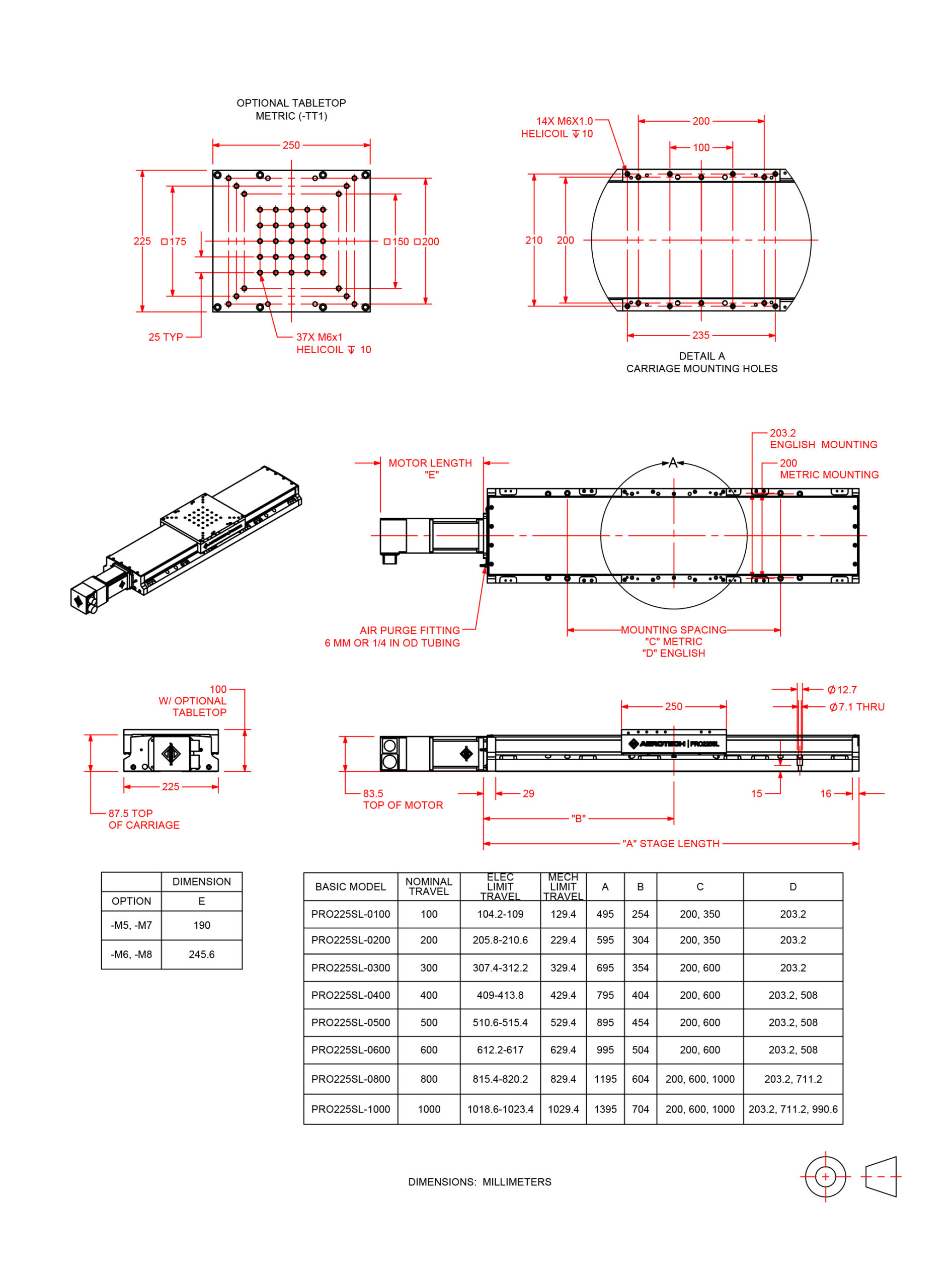

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Provides substantial payload-carrying capacity

- Best-in-class geometric performance ensures superior workpoint accuracy

- Excellent motion & positioning performance in a cost-effective package

- Rugged, reliable construction is ideal for versatile industrial use

- Hardcover & side seals offer protection against contamination & particulates

- Vacuum- & cleanroom-compatible versions available

Key Applications

PRO225SL mechanical bearing, ball-screw stages are extremely versatile, trusted and proven in medium- and high-performance applications, such as:

- Laser material processing

- Precision metrology, inspection & microscopy

- Electronics & circuit board manufacturing & inspection

- Display processing

- Synchrotron & light source experiments

- Medical device manufacturing

- Semiconductor fabrication

- Fiber optics & silicon photonics processing

- Additive manufacturing & precision assembly

Rugged & Reliable Mechanical Construction

A long-life recirculating linear guide bearing system, a precision-ground ball screw and a low-friction sealing solution make the PRO225SL an attractive choice for industrial applications such as laser machining, precision metrology, and electronics manufacturing and inspection. The PRO225SL’s durable construction provides protection from debris while the side seals prevent particulate matter from entering the stage. The curved hardcover design provides a natural shape that prevents excessive contamination from collecting on the stage. Capable of accommodating an ample payload range, PRO225SL stages are easy and intuitive to integrate, set up and operate. They also deliver an exceptionally long lifetime of consistent positioning performance.

Design & Integration Flexibility

The PRO225SL is designed with many standard features and options that make it incredibly flexible and allow it to be easily tailored to your specific application. The base mounting holes are accessible from the outside of the stage, allowing for easy horizontal or vertical mounting to both metric and English optical tables and other interfaces. The stage tabletop comes standard with a metric mounting pattern to accommodate your payload, process equipment or even another axis of motion.

Brushless servo motors are available with a variety of encoder feedback options, providing electrical resolutions ranging from 0.5 µm down to the sub-nm level. For vertical applications, the motor can be equipped with a fail-safe holding brake.

PRO225SL stages can be prepared for use in special environments by request. Contact us to learn about compatibility in vacuum chambers, cleanrooms and more.

Automate with Professional-Grade Motion

Our PRO-series stages are available in many sizes and configurations to accommodate an equally diverse range of user needs and application requirements. In addition to the PRO-SL series of ball-screw stages, we offer PRO-LM direct-drive linear stages, which are equipped with powerful linear motors for smooth, high-dynamic performance. PRO stages are offered in six widths ranging from 115 mm to 560 mm (depending on your application’s space constraints and payload requirements) plus travel lengths ranging from 50 mm to 1000 mm or longer. Also available in a vertical elevator-stage variant, our PRO-SV long-travel lift stages offer heavy-duty lifting capacity and can be easily mounted to PRO-SL and PRO-LM linear stages.

Aerotech PRO-series stages make it easier to build and integrate multi-axis assemblies and motion systems–whether you prefer to do it yourself or leave it to our motion and automation professionals.

Ordering Information

PRO225SL Series Linear, Ball-Screw Stage

Travel (Required)

| Option | Descsription |

| -0100 | 100 mm travel stage |

| -0200 | 200 mm travel stage |

| -0300 | 300 mm travel stage |

| -0400 | 400 mm travel stage |

| -0500 | 500 mm travel stage |

| -0600 | 600 mm travel stage |

| -0800 | 800 mm travel stage |

| -1000 | 1000 mm travel stage |

- Other travel options are available upon request. Contact Aerotech for more information.

Tabletop (Optional)

| Option | Description |

| -TT1 | Tabletop with metric dimension mounting |

- Other tabletop options are available upon request. Contact Aerotech for more information.

Motor (Optional)

| Option | Description |

| -M5 | BM250 brushless servomotor and 2500-line TTL encoder |

| -M6 | BM250 brushless servomotor, 2500-line TTL encoder, and brake |

| -M7 | BM250 brushless servomotor and 1000-line 1 Vpp encoder |

| -M8 | BM250 brushless servomotor, 1000-line 1 Vpp encoder, and brake |

- Other motor options are available upon request. Contact Aerotech for more information.

Motor Orientation (Optional)

| Option | Description |

| -2 | Bottom cable exit, optional orientation |

| -3 | Left-side cable exit, standard orientation |

- Other motor orientation options are available upon request. Contact Aerotech for more information.

Limits (Required)

| Option | Description |

| -LI1 | Normally-closed limit switches; 5 VDC with 9-Pin D connector |

- Other limit options are available upon request. Contact Aerotech for more information.

Coupling (Optional)

| Option | Description |

| -CP1 | Coupling for 0.500 inch diameter shaft |

Lifting Hardware (Optional)

| Option | Description |

| -LF | Lifting hardware |

- Lifting option only available on travels 300 mm and greater. Lifting should never be ordered on the upper-axis of an XY set (only order on lower-axis).

Metrology (Required)

| Option | Description |

| -PL0 | No metrology performance plots |

| -PL1 | Metrology, uncalibrated with performance plots |

| -PL2 | Metrology, calibrated (HALAR) with performance plots |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

Accessories (to be ordered as separate line item)

| Option | Description |

| ALIGNMENT-NPA | Non-precision XY assembly |

| ALIGN-NPAZ | Non-precision XZ or YZ assembly |

| ALIGN-PA10 | XY assembly; 10 arc sec orthogonality. Alignment to within 7 microns orthogonality for short travel stages. |

| ALIGN-PA10Z | XZ or YZ assembly with L-bracket; 10 arc second orthogonality. Alignment to within 10 microns orthogonality for short travel stages. |

| ALIGN-PA5 | XY assembly; 5 arc sec orthogonality. Alignment to within 3 microns orthogonality for short travel stages. |

| ALIGN-PA5Z | XZ or YZ assembly with L-bracket; 5 arc second orthogonality. Alignment to within 5 microns orthogonality for short travel stages. |

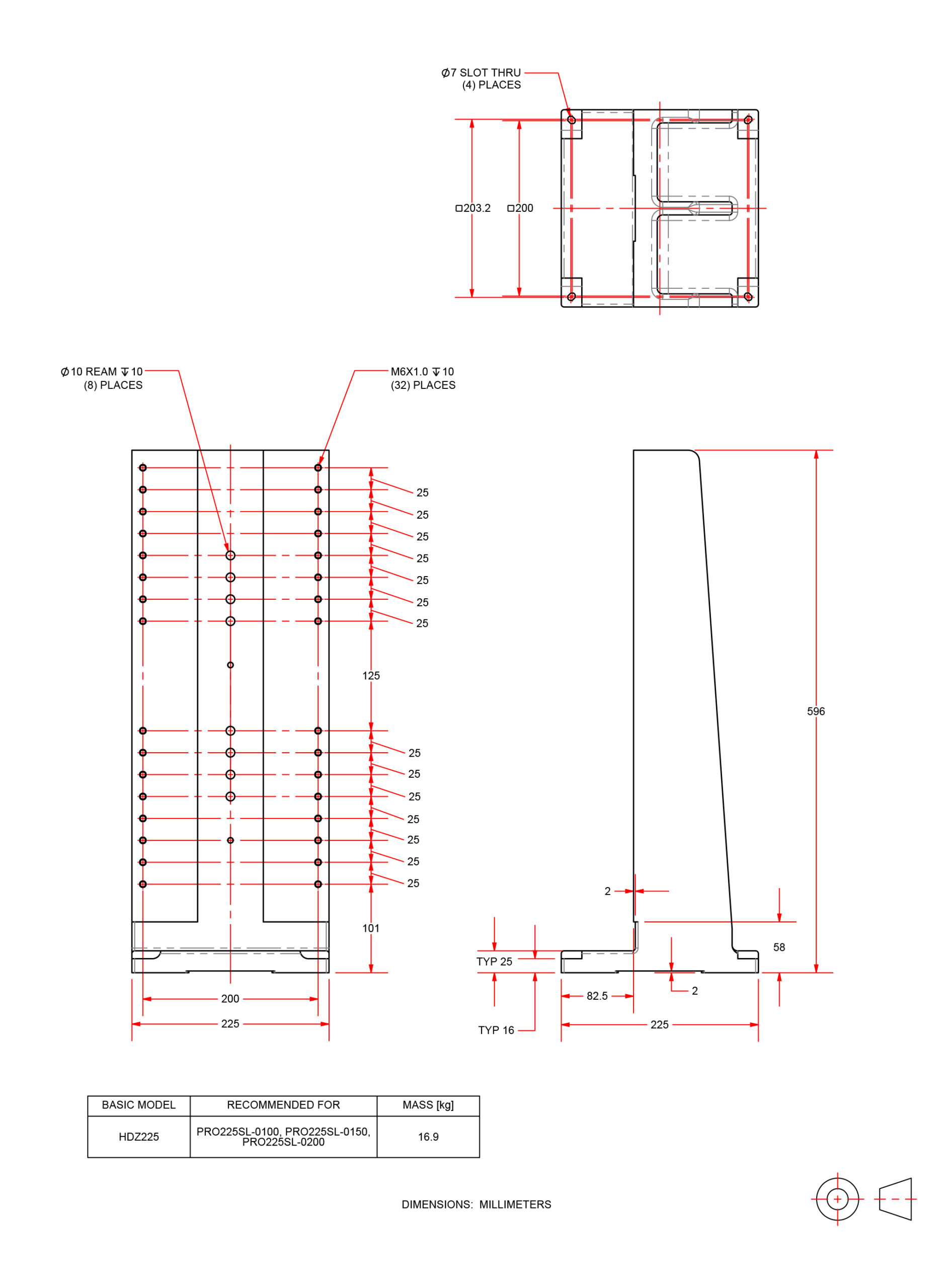

| HDZ225 | Right angle L-bracket for PRO225SL/SLE-100, PRO225SL/SLE-150, and PRO225SL/SLE-200 only. |