MPS130LZS Low-Profile Z Linear Motor Stages

MPS-LZS stages define a new benchmark for high-quality vertical motion that breaks the traditional tradeoff between precision and price. For demanding applications that require a careful balance of performance and cost, you no longer have to compromise on core technology. MPS130LZS stages feature anti-creep, crossed-roller bearings; ironless linear motors with exceptionally high force density; and an adjustable pneumatic counterbalance to offset up to 12 kg payload – so you get smooth, precise motion. Plus, MPS-LZS stages are form-factor compatible with our industry-leading ANT-LZS vertical nanopositioning stages, giving OEMs an easy and efficient means to scale.

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

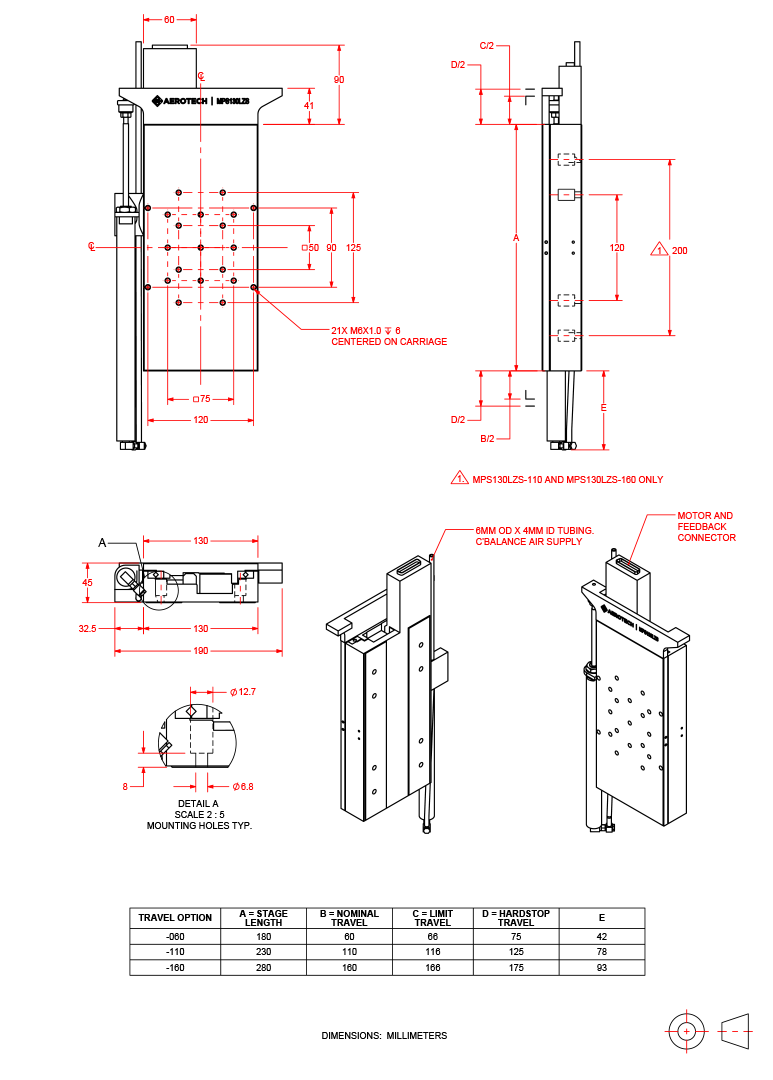

Dimensions

Ordering Info

Downloads

Description

Design Features

- Constructed with an ironless linear motor & crossed-roller bearings for smooth, precise motion

- Includes integrated, user-adjustable counterbalance to offset up to 12 kg payload for precise performance in the vertical direction

- Drop-in compatibility with Aerotech ANT130LZS nanopositioners offers seamless scalability for OEMs & machine builders

- Guaranteed performance specifications, including repeatability down to ± 0.2 µm

- Exceptional price-to-performance ratio contributes to low total cost of ownership

- Integrates easily into multi-axis assemblies & motion systems

Key Applications

MPS-LZS stages are ideal for cost-sensitive applications that require high precision, including:

- Photonics assembly & inspection

- Fiber alignment & optimization

- Wafer probing

- Optics manufacturing, testing & inspection

- Sensor testing & qualification

- Semiconductor processing & inspection

- Research & laboratory applications

Noncontact Direct-Drive Technology

Only noncontact direct-drive technology offers the robust, accurate and high-speed positioning necessary for mass production of precision devices. Compared to traditional screw-driven vertical and lift stages, MPS-LZS stages can move and accelerate faster and more precisely. This is because MPS-LZS stages use an ironless linear motor that eliminates cogging effects that would otherwise cause position errors and disturbances. Coupled with anti-creep, crossed-roller bearings, MPS-LZS delivers smooth, consistent vertical motion with outstanding dynamic characteristics to enhance your process capability at an attractive price point. The optimized drive and bearing combination, packaged in a compact form factor, offers distinct performance advantages in many applications such as high-precision positioning, fiber alignment, optics manufacturing and inspection, sensor testing and scanning processes that demand smooth and precise motion.

Flexible System Design

MPS-LZS stages feature convenient mounting patterns in the base and tabletop to allow for easy system integration. Multiple stages can be assembled together for flexible system designs and application-specific, multi-axis configuration. Because MPS-LZS stages are form-factor, drop-in compatible with our industry-leading family of ANT nanopositioners, you can effortlessly combine MPS-LM and ANT stages into multi-axis systems to achieve a balance of extreme performance and cost effectiveness.

Integrated Counterbalance

MPS-LZS stages are equipped with a minimally influencing pneumatic counterbalance to offset the gravitational forces from the carriage and payload. It includes a precision regulator for the exact dialing-in of the counterbalancing force. Unlike spring or magnetic counterbalance designs, the pneumatic counterbalance can be easily adjusted to exactly offset your payload’s weight—no ballast or counterweights needed. The counterbalance is installed standard on the left side of the stage; however, you can easily reconfigure it for right-side operation.

Advanced Control Architecture

MPS-LZS stages are best paired with Aerotech’s Automation1 Software-Based Machine Controller (iSMC). The Automation1-iSMC is a part of the Automation1 high-performance motion control platform, which also includes the Automation1 Motion Development Kit (MDK). Automation1 drives are networked to the controller over the HyperWire® fiber optic communication bus. This ultra-fast bus and premium servo motor drive hardware enable extreme levels of optimization across several axes of motion. Advanced trajectory generation capabilities such as multi-block lookahead minimize geometric errors in tight profiles by transparently regulating the motion profile. Advanced features such as Position Synchronized Output (PSO) improve process throughput and quality by triggering your process tool based on distance traveled—not time—to avoid errors stemming from acceleration and velocity changes.

Lowest Total Cost of Ownership

When your priority is a faster return on investment, MPS-LZS stages are an excellent choice. They combine a budget-friendly acquisition cost with the high precision and reliability you expect from Aerotech. We use reliable, high-quality core components and design elements — all engineered to minimize maintenance and maximize uptime – to ensure long-term value. Plus, MPS-LZS stages are perfectly paired with our Automation1 controller and cost-effective servo drives such as the iXA4, offering a comprehensive one-stop shop with minimal risk.

Ordering Information

Travel (Required)

| Option | Description |

| -60 | 60 mm travel |

| -110 | 110 mm travel |

| -160 | 160 mm travel |

Feedback (Required)

| Option | Description |

| -E1 | Incremental linear encoder, 1 Vpp amplified sine output |

| -E2 | Incremental linear encoder, digital RS422 output, 5 nm electrical resolution |

Mounting Plate (Optional)

| Option | Description |

| -MP | Mounting Plate |

Metrology (Required)

| Option | Description |

| -PL0 | No metrology performance plots |

| -PL1 | Metrology, uncalibrated with performance plots |

| -PL2 | Metrology, calibrated (HALAR) with performance plots |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |