PlanarDLA Two Axis Mechanical-Bearing Direct-Drive Stage with Aperture

Our PlanarDLA-series stages offer a clear aperture, high dynamics and exceptional geometric performance in a compact, low-profile package. These stages are essential for applications ranging from two-sided LED wafer processing where high dynamics and micrometer-level straightness are required to quasi-static optical metrology where high accuracy and precise geometric performance are necessary. Regardless of the application, the PlanarDLA is designed to meet a variety of needs with an array of configurable options.

Description

Specifications

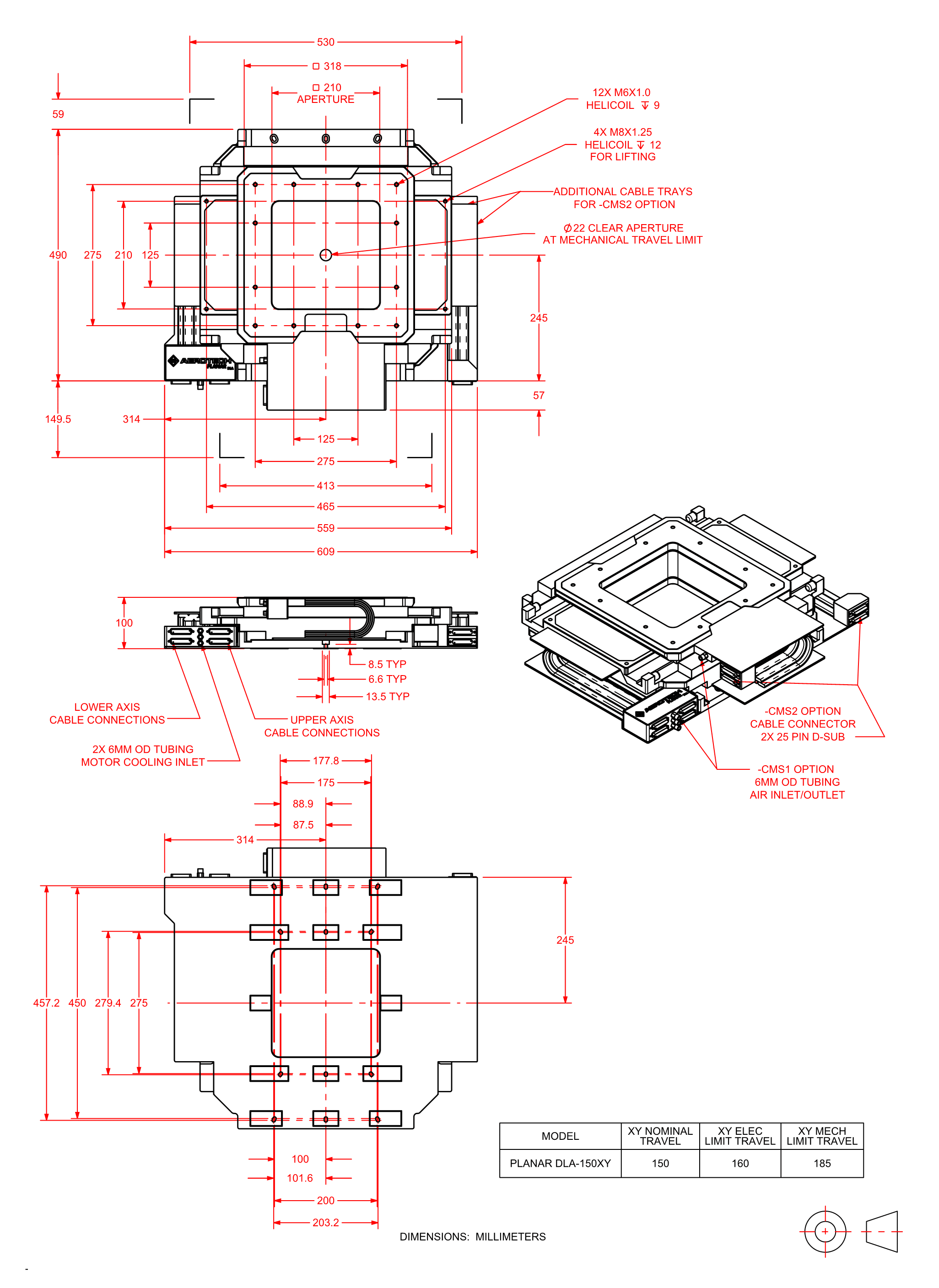

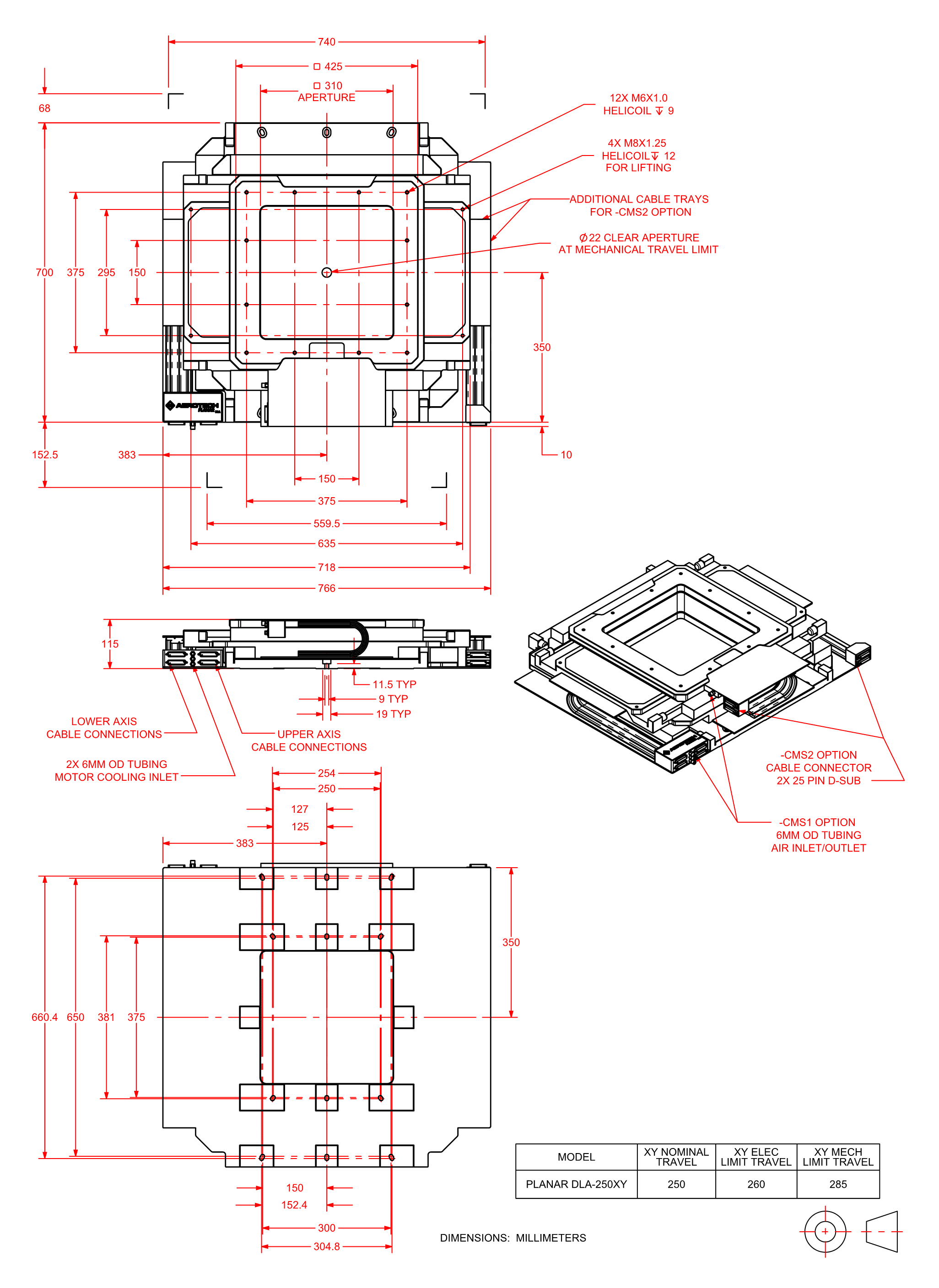

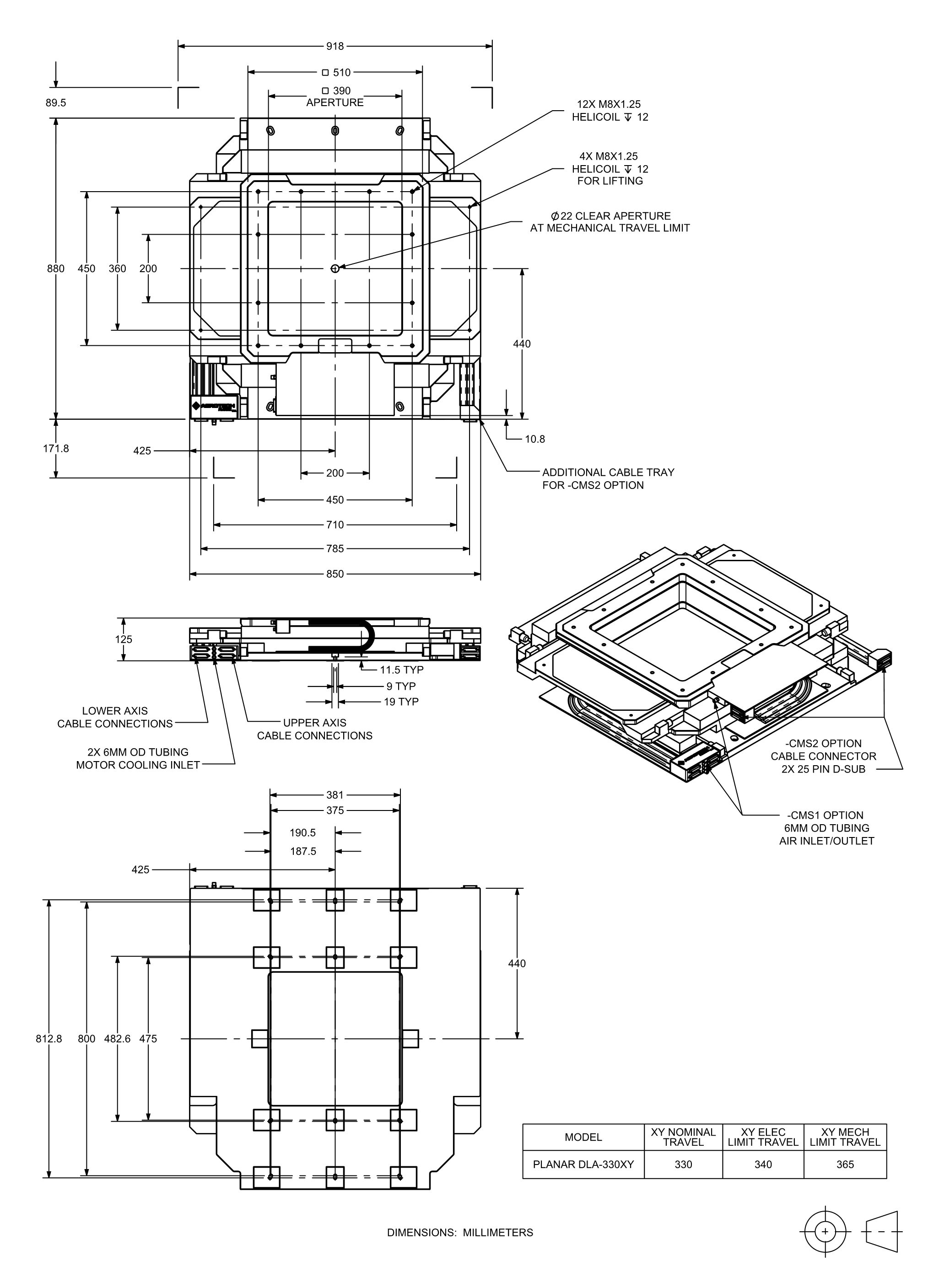

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Integrated, low-profile, XY, linear-motor stage with clear aperture

- Excellent geometric performance (straightness to ±0.5 µm, flatness to ±1.25 µm)

- Optimized for high-dynamic applications

- Speeds to 2 m/s and accelerations to 2g

- Integrated cable management

- Large selection - nine models in travel and accuracy

Ultra-Precise Stage Design

The PlanarDLA XY design provides for unparalleled planar geometric performance in applications where straightness and flatness of motion are critical. High-precision roller bearings, precision-machined surfaces, and noncontact direct-drive linear motors driving through the axes’ center-of-stiffness result in a positioning stage with exceptional geometric tolerances (straightness to ±0.5 µm and flatness to ±1.25 µm).

The PlanarDLA structural elements are optimized for high dynamics and high stiffness for the most demanding dynamic applications. With this optimized design, the PlanarDLA achieves high servo bandwidths while at the same time maximizing the clear aperture available and keeping the overall height to a minimum. Capable of achieving 2 m/s velocities and 2 g accelerations, the PlanarDLA enables high-throughput, high-accuracy processing resulting in superior process yield, and a low total cost of ownership.

Noncontact Direct-Drive Technology

Only noncontact, direct-drive technology offers high speed and accurate positioning coupled with maintenance-free operation and long service life. At the heart of the PlanarDLA is Aerotech’s proprietary direct-drive technology. This drive technology allows for unmatched performance compared to other competitive screw-based and linear motor designs.

All PlanarDLA stages are available with one or two motors per axis allowing optimization of each individual axis for the specific application and process. With two motors, the resulting drive force acts through the centers of friction and stiffness resulting in superior geometric performance and accuracy, while one motor per axis provides for a more economical choice if high-throughput and the strictest positioning performance is not required.

Variety of Cable Management Options

The standard cable management system on the PlanarDLA is integrated into the stage and optimized for long life and performance. Several standard options are available for additional servo axes, air/vacuum lines for vacuum chucks, or other process pneumatics.

Extreme Positioning Performance

The PlanarDLA is available in three positioning performance options. Relying on decades of experience in system-level design including not only positioning mechanics, but also software and electronics, Aerotech has developed advanced technologies to push the envelope of precision. High-performance -PLUS and -ULTRA options are available to enable accuracies and straightness values down to ±500 nm and orthogonality down to 5 µrad.

Ordering Information

PlanarDLA Two Axis Mechanical-Bearing Direct-Drive Stage with Aperture

| Option | Description |

| PlanarDLA-150XY | Linear motor XY table w/clear aperture; 150 mm x 150 mm travel |

| PlanarDLA-250XY | Linear motor XY table w/clear aperture; 250 mm x 250 mm travel |

| PlanarDLA-330XY | Linear motor XY table w/clear aperture; 330 mm x 330 mm travel |

Motor (Required)

| Option | Description |

| -M1 | 1 motor on lower axis; 1 motor on upper axis |

| -M2 | 1 motor on lower axis, 2 motors on upper axis |

| -M3 | 2 motors on lower axis, 1 motor on upper axis |

| -M4 | 2 motor on lower axis, 2 motors on upper axis |

Feedback (Required)

| Option | Description |

| -E1 | Incremental encoders, 1 Vpp on upper and lower axes |

| -E2 | Incremental encoders, 0.1 um TTL on upper axis, 1 Vpp on lower axis |

| -E3 | Incremental encoders, 1 Vpp on upper axis, 0.1 um TTL on lower axis |

| -E4 | Incremental encoders, 0.1 um TTL on upper and lower axes |

Cable Management (Optional)

| Option | Description |

| -CMS1 | Cable management for air/vacuum line |

| -CMS2 | Cable management for air/vacuum line and 3rd axis motor/feedback |

Performance Grade (Required)*

| Option | Description |

| -PL1 | Base performance |

| -PL3 | High-performance, PLUS |

| -PL4 | Ultra-high accuracy 2D performance, ULTRA |

- -PL3 and -PL4 performance grades require Aerotech controller.

Integrated (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |