Automation1 GL4 Galvo Laser Scan Head Linear Drive

The Automation1 GL4 is a high-performance, closed loop 2-axis linear servo drive for controlling our AGV laser scan heads. With an effective scanning resolution of greater than 24-bit and advanced features like Infinite Field of View (IFOV), Position Synchronized Output (PSO) and Enhanced Scanner Control (ESC), the GL4 stands out as a superior scan head drive solution for your most demanding high-precision applications.

Description

Specifications

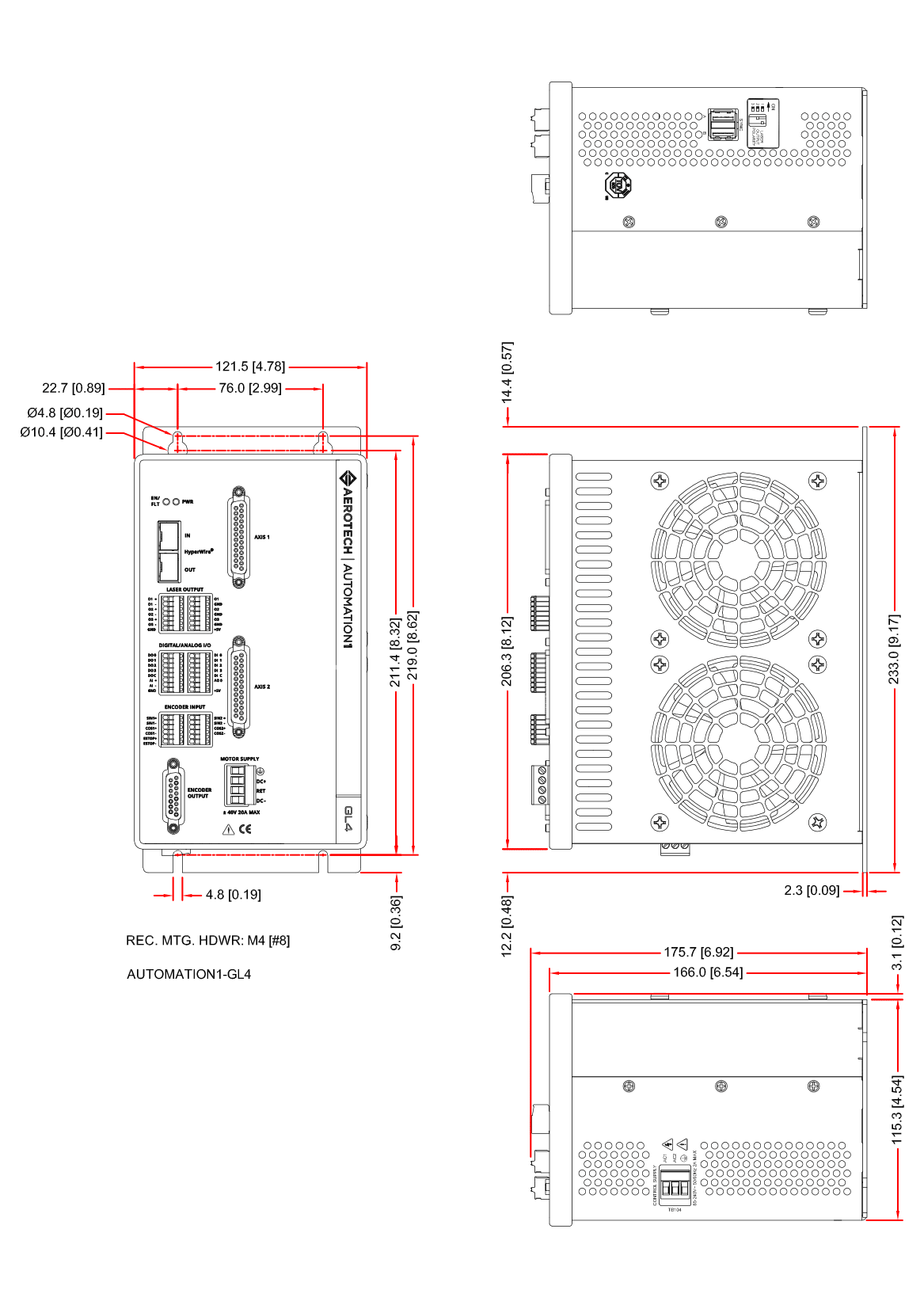

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- 100 kHz trajectory rate & 200 kHz servo rate eliminate speed-related part distortion such as necking on circles & rounding of corners

- Effective scanning resolution of >24 bit provides industry-leading resolution resulting in micron scale accuracy & repeatability for Aerotech AGV scanner products

- On-board real-time 2D calibration for both planar distortion & power correction enable accurate laser positioning & uniform power distribution

- External clock input for synchronization with mode-locked lasers

- Infinite Field of View (IFOV) combines standard linear & rotary motion to produce scanner trajectories with single-digit micron accuracy over most work area sizes

- PSO allows for commanded laser pulses at up to 12.5 MHZ & latencies as low as 80 nanoseconds, enabling real spatial domain pulse control

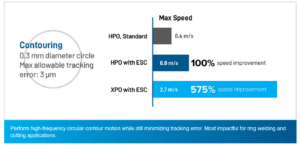

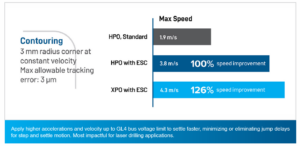

- Optional Enhanced Scanner Control (ESC) is a real-time trajectory optimization tool that dramatically improves tracking error for all motion types

Automation1

Powered by Automation1, the GL4 is more than a scan head drive – it’s a fully featured, real-time PC-based automation controller that can accommodate up to 32 servo axes or five scanners. Coordinate up to 64 active, simultaneous tasks and control an entire machine programmed with AeroScript™ – or use the .NET, C and Python APIs to create your own HMI. The low-latency hyperwire network allows all axes to perform low-latency motion, enabling complex kinematics such as 5-axis contouring with laser scan heads and servo axes – something no other scanner control solution on the market can do.

Driving the Industry’s Most Accurate & Dynamic Scan Heads

The GL4 2-axis linear servo drive is specifically designed for use with the AGV Scan heads listed below. Use it to drive a single 2D scanner or in concert with the Automation1 XL4 linear single phase servo drive for AGV 3D and 5D scan heads (all connect via a HyperWire communication bus).

- AGV-HP(O) - High accuracy 2D scanner

- AGV-XP(O) - Extreme dynamic, high accuracy 2D scanner

- AGV-3D - High accuracy 3D scanner

- AGV-5D - 5-axis micromachining precession scanner

Advanced Software & Electronics

The GL4 uses advanced interpolation electronics to provide up to 26 bits of effective resolution. With its 200kHz full servo state control, the GL4 uses closed loop position feedback to enable zero tracking error trajectories via feed forward velocity control. This Enhanced Tracking Control (ETC) software allows for precise motor tuning and trajectory mapping. Additionally, on-board real-time 2D calibration ensures accurate beam placement over the entire field of view.

Infinite Field of View (IFOV)

Our Infinite Field of View (IFOV) is a unique, industry-leading solution for the synchronization of linear or rotary servo axes with laser scanners. IFOV produces significant throughput improvements while eliminating stitching errors and part quality issues that result from overlapped and mismatched laser processing. By combining the high-dynamic capabilities of galvo scanners with the travel range of servo stages, parts significantly larger than a scanner’s traditional field of view can be processed continuously with no need to stitch individual working areas together.

Position Synchronized Output (PSO)

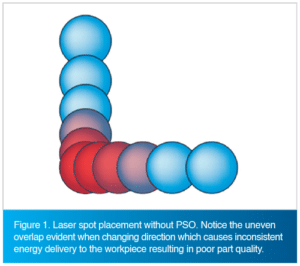

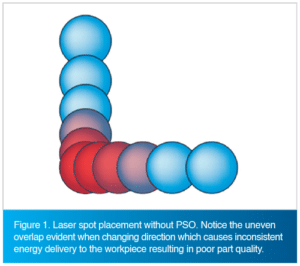

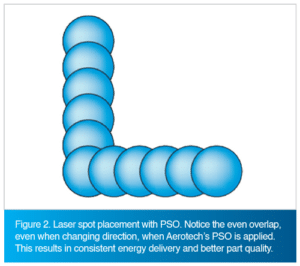

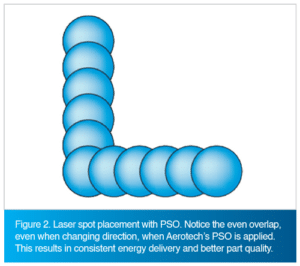

Our Position Synchronized Output (PSO) enables you to accurately place a laser spot as a function of X/Y axis position, and it’s a key feature of our linear positioning tables for laser processing applications (see Figures 1 and 2). The GL4 brings this functionality to scanner applications both within the scanner's effective area and within a larger infinite field of view, with IFOV driven by traditional linear and rotary motion. The ability to accurately trigger the laser as a function of position eliminates the need to program mark, jump and polygon delays, resulting in reduced programming complexity. This unique scanner feature enables commanded laser pulses at up to 12.5 MHz and with latencies as low as 80 nanoseconds, allowing for real spatial domain pulse control even under the highest acceleration trajectories.

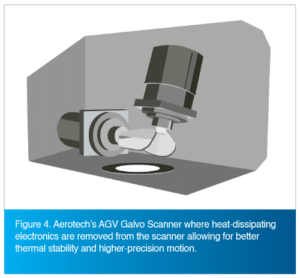

Remote Linear Amplifier & Drive Architecture

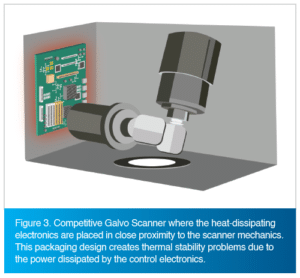

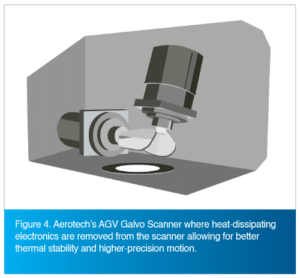

The GL4 uses linear amplifiers, which are the most stable high-performance method for driving galvo scan head motors and provide improved velocity control and position stability. The amplifiers and servo drive components are combined in the GL4’s chassis and intentionally separated from the galvo scan head (an AGV-HP(O), for example) to minimize thermal noise and drift and reduce the scan head’s mass and size. Removing the heat source from the scanner improves system accuracy (see Figures 3 and 4), maximizing performance and precision – and setting our scanner solutions apart from the rest.

Enhanced Scanner Control (ESC)

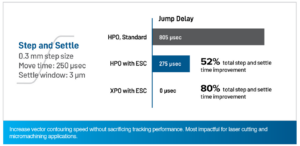

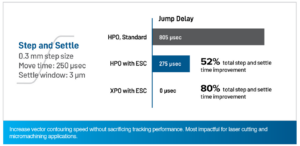

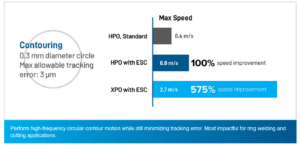

The GL4 offers optional Enhanced Scanner Control (ESC), a powerful drive hardware and firmware configuration that enables real-time trajectory optimization of all motion types when paired with an AGV-HPO, AGV-XPO, AGV3D or AGV5D product. It delivers dramatic throughput improvements for any motion profile that has a tangible impact on scanner throughput.

Perform step and settle motion that settles faster, enabling the minimization or elimination of jump delays for high frequency motion.

Perform high-frequency circular contouring motion at higher speeds without sacrificing tracking error. This enables faster welding, cutting and drilling scanner motion profiles.

Perform high-precision cutting profiles with vector motion that will exceed process throughput expectations.

Feature |

Description |

| Motor Supply | ±40 VDC max |

| Control Supply | 85-240 VAC; 50-60 Hz |

| Digital Inputs | Four Optically Isolated |

| Digital Outputs | Four Optically Isolated |

| Analog Inputs | One 16-Bit Differential; ±10 V |

| Analog Outputs | Two 16-Bit Single-Ended; ±10 V |

| Laser Outputs | Three Optically Isolated; 3 TTL |

| Emergency Stop Sense Input (ESTOP) | Standard; 24 V Opto-Isolated |

| Position Synchronized Output (PSO)(1) | Standard: - Three-axis PSO - Three-axis Part-Speed PSO |

| Enhanced Scanner Control (ESC)(2) | Optional: ESC-specific drive hardware & firmware configuration enables ESC feature. |

| Interpolated Feedback Output | Yes |

| Communication Bus | HyperWire® fiber-optic interface |

| Operating Temperature | 0 to 50°C |

| Storage Temperature | -30 to 85°C |

| Weight | 2.9 kg |

| Servo Loop Rate | 200 kHz |

| Compliance | CE approved, NRTL safety certification, EU 2015/863 RoHS 3 directive |

Ordering Information

GL4 Series (Required)

| Option | Description |

| GL4 | Single-phase linear amplifier |

Current (Required)

| Option | Description |

| -20 | 20 A peak; 5 A continuous |

Optional Drive Enhancements

| Option | Description |

| -ESC0 | without Enhanced Scanner Control |

| -ESC1 | with Enhanced Scanner Control (for use with the AGVHPO) |

| -ESC2 | with Enhanced Scanner Control (for use with the AGVXPO) |